UTILIZATION OF DAIRY BYPRODUCTS FOR ECONOMIC RETURN

,Serlene Tomar1, Annada Das2, Kaushik Satyaprakash3 and Narendra Tomar4

1 Department of Livestock Products Technology, College of veterinary Science and Animal Husbandry, Rewa, M.P.

2Department of Livestock Products Technology, West Bengal University of Animal and Fishery Sciences, Belgachia, Kolkata, West Bengal.

3Department of Veterinary Public Health & Epidemiology, Faculty of Veterinary and Animal Sciences, Banaras Hindu University, Mirzapur, Uttar Pradesh

4Veterinary Assistant Surgeon, Rewa, M.P

A dairy by-product may be defined as a product of commercial value produced during the manufacture of a main product (De, 2001). Examples: whey, butter milk, skim milk, ghee residues etc. The aggregate of dairy by-products are enormous. For every pound of butter made there are 15-20 pounds of skim milk (from cream used for butter) and about 3 pounds of butter milk and for every pound of cheese nearly 9 pounds of whey. If not properly utilized, may create acute problem of environmental pollution. The high protein, fat, and sugar content in them give a substantial organic load and biochemical oxygen demand (BOD). Proper utilization of dairy byproducts leads to profit/economic return.

Current scenario

- A low per capita availability of milk, higher proportion of buffalo milk, poor quality of raw milk, lack of organized manufacture of products, lack of adequate technology, high cost of new technologies, lack of in-house R & D, lack of proper infrastructure, lack of indigenous equipment and plants etc. have been the problems mainly associated with the production and utilization of dairy by-products in India.

- It is only after economic liberalization and de-licensing of the dairy industry in 1993, that dairy by-products, which were mostly neglected by the dairy plants earlier started receiving due attention.

- A number of by-products based dairies with large automatic and continuous manufacturing plants have been set up.

- In India, the major source of whey (above 70%) is from the production of chhana and paneer, the production of which is mostly scattered over numerous small holdings.

- In the absence of systematic surveys/statistics, the predicted value for total whey production in India is estimated at 5 million tonnes per annum.

- The exact amount of buttermilk production in India is not estimated. However, based on conversion of 6.5% of total milk production into creamery butter, it can be estimated that over 0.4 million tonnes of buttermilk is produced in organized sector annually as a by-product.

- In addition, a substantial amount of lassi (sour buttermilk) is also produced during the manufacture of makkhan directly from fermented milk (curd). Total annual production of buttermilk in India is estimated at 35 million tonnes.

- Taking an average yield of ghee residue as one-tenth the quantity of ghee produced, at present level of ghee production (30.4 million tonnes), the GR produced works out to more than 3 million tonnes per annum.

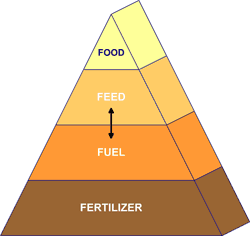

The 4 F pyramid

The 4 F pyramid represents the hierarchy of dairy byproducts utilization. Following human consumption, the highest potential market value has been for supplemental animal feed application, followed by fuel and fertilizer.

Classification of dairy byproducts & their uses

Important by-products available from the dairy industry and their principles of utilization:

| S.No | Main Product | By Product | Processing method | Products Made |

| 1 | Cream | SKIM MILK | Pasteurization | Flavoured milk |

| Sterilization | Sterilized flavoured milk | |||

| Fermentation | Cultured Buttermilk | |||

| Fermentation and Concentration |

Concentrated sour skim milk | |||

| Concentration | Plain and Sweetened Condensed skim milk | |||

| Drying | Dried skim milk or Skim milk powder or Non Fat Dry Milk (NFDM) | |||

| Coagulation | Cottage cheese, Quarg, edible casein | |||

| 2 | Butter | BUTTERMILK | Fermentation and Concentration |

Condensed buttermilk |

| Concentration and drying | Dried buttermilk | |||

| Coagulation | Soft cheese | |||

| 3 | Cheese, Casein, Channa, Paneer |

WHEY | Fermentation | Whey beverage, Yeast whey |

| Concentration | Plain and sweetened condensed whey, whey protein concentrate, whey paste, lactose | |||

| Drying | Dried whey | |||

| Coagulation | Ricotta cheese | |||

| 4 | Ghee | GHEE RESIDUE | Processing | Sweetmeat, Toffee, Sweet paste |

- SKIM MILK

Skim milk is that portion of whole milk which remains after the removal of the cream. According to PFA (1997), fat from the skimmed milk has been removed mechanically and shall not contain more than 0.5% milk fat and not less than 8.5% milk solid- not fat. It is rich in solid-not-fat content and has high nutritional value. It may be utilized for manufacturing of main dairy products or preserved by removing moisture in spray dried form to obtain skim milk powder. When skim milk is consumed in any of these two products then it is not considered as by-product. It is considered as by-product when it is either not economically utilized or utilized for derived product like casein, co-precipitate, protein hydrolysate etc.

Casein is the major protein in milk and constitute 80% of total protein content and about 20% is whey or serum protein. Casein is commercially made from skim milk by precipitation by acid to make acid casein & coagulation with rennet to make rennet casein. In addition to these there are other commercial casein products: coprecipitate & caseinates.

SKIM MILK AS HUMAN FOOD-

The best use to which skim milk can be applied is as human food, in its uncooked state as flavoured milk. The use of skim milk instead of whole milk as food, in its natural state, is simply a matter of taste and habit. A quart of skim milk contains more proteins than the whole milk and the former is cheaper and better than the latter as a substitute for meats and other animal feeds. A report upon dietary studies made at University of Tennessee in 1987 said that the nutrients in milk are equal in physiological value to those of meats and are far less expensive.

Skim milk as a substitute for water in preparing various dishes–

There is no waste and a gain in food value. This is especially true for making bread. Bakers have long known the value of skim milk in bread making, and they give the reasons for using skim milk instead of water:

- It keeps the loaf moist for a longer time

- It makes a closer loaf

- It improves the eating quality of bread

- The sugar in milk caramel in baking and browns the crust

Cheese made of skim milk –

Skim milk may be made into cheese having high food value, and may be used to advantage in cooking. In Europe both hard and soft cheeses, and several varieties of these, are made from the skim milk. Cottage cheese also called pot cheese or smear case, is made from skim milk. Skim milk is converted to Filled cheese in Europe it is known as ‘Margarine cheese’. In this, to the skim milk is added some cheap form of fat, usually of animal origin, but sometimes vegetable, to replace the original fat of milk.

SKIM MILK AS FEED FOR DOMESTIC ANIMALS/BIRDS:

Next to human food, the most profitable use to which skim milk can be applied is in feeding domestic animals/birds. Some important facts which proved skim milk as a good livestock/poultry feed are:

- Skim milk gives the best return when fed to very young animals, constituting the greater part of their food.

- It next best for animals making rapid growth but which need food other than milk and mainly of a more carbonaceous character

- Except for the very young, skim milk gives much better results when used in combination with other materials, generally grains, than when fed alone. It gives a better return for poultry than livestock.

FERTILIZER FROM SKIM MILK-

Skim milk possesses a positive value as a fertilizer.

Skim milk has not higher value as manure, if directly applied to growing crops.

CASEIN FROM SKIM MILK AND ITS USES –

Casein when combined with the oxides and salts of the metals of calcium group, casein forms a cement-like compound, insoluble in water.

- Paper dressed with casein

- Use of whey from casein as hog feed

- Fertilizer from casein

- Casein as a substitute for celluloid

SKIM MILK IN WHITEWASH AND WOOL MANUFACTURE-

The use of skim milk in whitewash has been known to prevent the coating from peeling off. It is mixed with hydraulic cement, or water lime, so as to make a thin paint, and laid on with a broad, flat brush. One pound of cement to a gallon of milk is the usual mixture, and should not be stirred much, because more stirring can cause hardness. This makes an excellent, durable, and inexpensive covering for any structure of wood or stone. If nothing but cement and milk are used, the color will be light, yellowish brown, but other colouring material can be added in form of dry pigment. Emulsion of olive oil and skim milk are used in wool manufacture as a dressing for the wool.

- BUTTER MILK

Buttermilk is an important by-product obtained during the manufacturing of butter. Normally, in our country three types of buttermilk are produced:

- Sweet cream buttermilk

- Sour buttermilk

- Desi (lassi) buttermilk

The sweet and sour buttermilks are produced in organised sector and lassi at household levels in small quantities. Buttermilk has high phospholipid content that has a significant function as emulsifiers in food systems and makes this dairy ingredient interesting for use as a functional ingredient in an array of food products like chocolate, cheese seasonings, margarine, bread, ice cream mixes, or yoghurt. The buttermilk concentrate rich in phospholipids has been utilized in processed cheese spread to improve its organoleptic, rheological, and functional properties. It is used in processed cheese spreads makes this dairy product useful as a functional food.

Sweet buttermilk, condensed by heat and vacuum, supplemented at levels of 4 or 6% in regard to cheese milk improved the yield of pizza cheese with the contribution of denatured WP. Buttermilk has been verified as an ingredient in buffalo milk-derived chhana, an indian-style soft cottage cheese analogue. Substitution of milk with variable proportions of sweet buttermilk (from 0 to 50%) was technologically tested in cream cheese and the authors revealed that the progressive increase of buttermilk percentage was followed by increase in moisture and yield. Buttermilk has been added to reduced-fat cheese up to 40% and was found to improve the sensory scores in comparison to the control.

Utilization of Sweet cream buttermilk-

- Sweet cream buttermilk can be used in beverage form and in fluid milk industry as a milk extender.

- Sweet cream buttermilk resembles skim milk in gross chemical composition and is usually admixed with bulk of skim milk for further spray drying or even product manufacture in dairy plants.

- Buttermilk is also used to manufacture soft varieties of cheese, paneer, fermented milks and traditional milk products.

- Beverage: Butter milk is consumed in plain and spiced form throughout the year and used as refreshing drink in summers.

- Market milk: Sweet cream buttermilk produced in in organized dairies is partly admixed with whole milk for fluid milk supply. It has been observed that use of sweet cream buttermilk in market milk for toning of buffalo milk improves the palatability, viscosity, and heat-stability.

- Fermented milk product: Curd is prepared by incorporating sweet cream buttermilk into whole milk has soft body which is probably due to change in electric charge on casein during churning, the presence of phospholipid and free fat in buttermilk.

- Paneer : Good quality of paneer can be prepared by from low fat milk by incorporating buttermilk solids to buffalo milk.

- Cheese: the replacement of skim milk with sweet cream buttermilk results into softer body due to the presence of higher amount of fat globule membrane materials in buttermilk.

- Other material: Sweet cream buttermilk can also be used to manufacture products like: khoa, kheer, rabri. Buttermilk can replace the skim milk powder in manufacture of gulabjamun mix powder.

Utilization of desi and sour cream buttermilk –

Desi buttermilk, on the other hand, has long been an important domestic beverage in India. It has high nutritive and therapeutic value. It also finds its way in the preparation of a host of items such as kadhi, dhokla and idli. Also a number of state dairy federations and private plants sell salted and spiced buttermilk in 200 ml pouches. Surat-based Sumul does business out of selling buttermilk (chhach) in and around the city.”Sumul chhach” in 500ml packs reaches practically every nook and corner of Surat, covering over 850 retail outlets. In the summer, an average sale of chhach is around 45,000 litres a day.

- GHEE RESIDUES

Ghee residues are the by-products of ghee manufacturing industry and is produced in large quantities in India. About 30–35% of the milk produced in India is converted into ghee. A blackish brown residue mainly the SNF part of cream was coagulated out during ghee preparation as a by-product when cream is heated is known as ghee residue. It is obtained as moist brownish sediment after molten ghee has been strained out.

Nutritional property: Ghee residue is rich in protein and fat apart from containing considerable amount of mineral and can be used as human dietary supplement.

Antioxidant property: Ghee residue is rich in natural antioxidant and its antioxidant properties are due to its constituents affected by various technology parameters. Its antioxidant properties are due to lipid and non-lipid constituents.

Flavouring properties: Ghee residues are also rich and natural source of flavour compounds like FFA, carbonyls, lactones.

UTILIZATION OF GHEE RESIDUES –

Most dairy plants in India have not been utilizing GR except for fat extraction. Most of the ghee residues goes to the waste. In dairy plants, attempt has been made to recover as much ghee as possible from ghee residues. Two recovery methods are there: pressure technique and centrifugal process. Ghee residues can be utilized in number of products like chocolate, burfi, samosa filling, chapatis etc. Physico- chemical properties of processed ghee residues are suitable for preparation of confections like:

- Preparation of candy

- Preparation of chocolate

- Preparation of edible paste

- Preparation of burfi type sweet

- Preparation of bakery products

- WHEY

When cheese is made from milk, whether the milk be skimmed or not, the only byproduct is whey. Whey also results from separating the casein from skim milk. From every hundred pounds of milk is converted into cheese, about 90 pounds of whey is obtained. Whey is a watery, highly perishable, semitransparent liquid in appearance, composed of about 93% of water and 7% of solid (albumin, sugar, ash, casein, fat) and is a useful resource of nutrients.

WHEY PROTEINS-

Ultrafiltration is one of the most potential technologies for processing of whey to recover whey proteins in India. In India, all the lactose, the total production capacity being about 15,000 tonnes per annum, is produced from UF permeate. These whey proteins are separated and purified from the liquid whey in an efficient membrane filtration process and subsequent spray drying to obtain either whey protein concentrate (65–80% protein in dry matter) or whey protein isolate (90% protein in dry matter)

UTILIZATION OF WHEY

Modern industrial processing technique such as ultrafiltration, reverse osmosis, new drying methods, hydrolysis, electrodialysis, ion-exchange, fermentation etc. have converted whey into major source of ingredient with different functional and nutritional properties. Presence of lactose, protein, minerals and water soluble vitamins make the whey highly nutritious product.

- Being a rich source of lactose, whey is good fermentation media for number of fermented product.

- In many applications, lactose in whole or deproteinised whey is hydrolysed to glucose and galactose, thereby increasing its sweetness, such lactose syrups are used sweet confectionery product and ice cream.

- Whey cheeses like Mysost, Gjetost are produced in Norway & Greece. Ricotta cheese is popular in Italy.

- A small percentage of whey is demineralised to produce dry demineralised whey for specialized uses, these include whey protein based infant formulas and other medical and nutritional product that require lactose, special nutritional quality of whey protein and low mineral content.

- Demineralised sweet whey is also used in coffee whitener, milk shakes, citrus drinks, animal feed, confectionary, bakery goods, whey drinks, salad dressings.

VALUE OF WHEY AS FEED FOR HOGS

Numerous records shows whey has considerable value as food for swine, when mixed with other material. Several trials indicates that whey has same feeding value for hogs as half the same weight of skim milk. A number of comparative trials have shown that sweet whey to be more valuable than sour whey for feeding pigs.

WHEY FOR CALVES AND COWS

Some trials with calves shows whey to have about half the value of skim milk. Sweet whey has also been fed to milch cows, in an experiment and satisfactory results obtained where 10-20 pounds were given to each animal, in addition to other food.

WHEY FOR HUMAN INVALIDS

Ordinary whey is considerably used for invalids, especially in case of lungs and chlorotic diseases, mainly as an aid to digestion. An article known as “wheyn” has been patented, which is a purified and sterilized whey, free from albumen and fat, and constitutes a nourishing and mildly stimulating beverages.

Other uses of dairy byproducts

- Dairy by-product as fuel : High strength dairy by-products contain significant concentrations of organic compounds that can potentially be converted to renewable energy like Biogas.

- Whey protein-based edible films are a viable alternative packaging process for food and improvement of shelf life.

- Ghee residue is a good source of proteins, and about 100,000 tonnes of proteins can be recovered annually from GR only, and this can help in combating severe problem of protein-energy malnutrition.

- Potential uses of either crude or purified caseins include the production of plastics, adhesives, gels, composites and films.

Biotechnological advancements in dairy byproducts utilization

- Biomass production

- Bioplastics

- Biofertilizer

- Biofuels

- Single cell protein production

- Organic acid production

- Bioactive peptides

- Polysaccharides

- Biosurfactants (BS)

CONCLUSION

- During the manufacture of different dairy products, the inevitable problem of utilization of by-products is encountered. Because of their unique and important nutrients available in the by-products, they have to be utilized in a proper manner considering the welfare of the general masses.

- The newly acquired economic importance of a by-product will make it a main product in the future.

- During the last few years a considerable amount of attention has been centered on the industrial utilization of some of the by-products of the dairy industry.

- The profitability of the dairying can be greatly improved by economically utilizing the dairy by-products and it can be considered as a prerequisite to profitable dairy business.

- With the advancement in technology, the scope is wide open for creating newer channels of utilization of the by-products arising from dairy processing.

- https://www.pashudhanpraharee.com/utilization-of-slaughter-house-by-products-for-sustainable-meat-industry/

- https://gcwgandhinagar.com/econtent/document/15871824941FSTSE0601_ByProductsOfDairyIndustryAndTheirUtilization.pdf