Feeding Total Mixed Ration (TMR) to High Yielding Dairy Cattle

Now a day it’s the time for organized and big farms which needs feeding of animals precisely. Precise nutrition is possible with the help of TMR feeding concept. Organised farms should be converted to TMR feeding concept for improving the production performance of animals and also for economic rearing. While comparing the advantages and disadvantages of TMR feeding, always advantages are staying high. A carefully designed TMR feeding system in farms really payoff a lot. Good management of the farm should be coupled with TMR feeding for better productivity. With the dairy farmers struggling to tackle the rapidly increasing production cost, a group of veterinary doctors says that the recent introduction of Total Mixed Ration (TMR) can effectively reduce the production cost in the sector.

Feed accounts to be more than 50-60% of total cost in livestock enterprise. Various systems of feeding have been developed for optimum utilization of feed resources for sustainable livestock production. India possesses a huge livestock population contributing to about 24.7% share in agriculture GDP (GOI, 2011) providing livelihood to 70% rural families. In the recent years, the allocation of land for fodder cultivation has been decreasing tremendously because of intense urbanization. Also, the cost of concentre feed ingredients has gone up because of competition with human food chain (Ramachandra et al, 2007). Therefore, the farmers are unable to provide balanced feed to the livestock resulting in the sub-optimal performance. This leads to the exploration of alternate feed resources which do not compete with the human food chain. Fibrous crop residues and agro-industrial by-products play an important role as a source of feed for ruminants, but the utilization of these feeds is limited because of poor nutrient content and digestibility. Furthermore, the availability of straws is widespread and they play a strategic role particularly in times of scarcity. Another advantage of crop residues is separate land allocation is not required for production and they obtain as a by-product from the main agriculture produce. The feeding value of these crop residues can be increased by incorporating them into total mixed rations (TMR) by fortifying them with required nutrients (Sharma et al., 2010). TMR can be defined as a mixture of both the roughages and the concentrate ingredients, formulated and mixed thoroughly to form a balanced feed. It can form a sole feed source for a 24 hour period and can be offered ad libitum for best results. The TMR is a best option for landless and small farmers for feeding their animals a balanced feed.

The surplus residues i.e. total residues generated minus residues for various purposes are typically burned in the fields or used to meet household energy needs of the farmers. The CP (%) content of crop residues ranged from 2.3 to 14.7 with an average of 5.6. Most of the crop residues are fibrous and are of low to moderate in nutritive value. The special physical and chemical characteristics and low levels of one or more nutrients limit the utilization of crop residues. Most of the crop residues are high in silica and lignin preventing the action of digestive enzymes leading to reduced nutrient digestibility. Hence, suitable processing methods have to be employed to enhance the utilization of crop residues. The most promising method proved to be best is the incorporation of crop residues in total mixed rations.

Preparation of total mixed ration (TMR)

TMR is prepared by using agriculture wastes, crop residues (Table 1) like wheat straw, paddy straw, maize/jowar stover, red gram/black gram/green gram/bajra straw, dry grasses and by-products like oil seed cakes, brans and molasses. The crop residues are first made into small pieces with the help of chopper and then they are ground to small particle size with the help of hammer mill type grinder and then the roughage and concentrate are mixed together in mixer to have a uniform blend. TMR can be fed either in mash form or pelleted by using expander-extruder technique.

Table 1. Ingredients (%) in total mixed ration

Roughage 50-70

Energy supplement 3-30

Protein supplement 5-20

Cereal by-products 0-30

Urea 0-1

Molasses 5-10

Mineral mixture 1-2

Salt 0.5-1.0

Vitamin supplement 10g/100kg

Different combinations of roughages and concentrate feeds can be used to prepare TMR for lactating cows, growing heifers and dry animals. Crop residues and locally available by-products can be used in the formulation in proportion as per the requirement of the animals. The proportion of roughage in TMR depends on the animal productivity and type of fibre (Table 2).

Table 2. Level of inclusion of some crop residues in total mixed rations

Agricultural crop residue Level of inclusion

Paddy straw 40-60

Wheat straw 30-60

Sorghum straw 20-60

Red gram straw 40-60

Soybean straw 30-40

Bajra straw 20-30

Sugarcane bagasse 15-40

Dried mixed grass hay 30-70

Cotton seed hulls 40-60

Red gram bhoosa 30-40

Ground nut haulms 40-50

Sunflower heads 30-50

Formulation of total mixed rations for dairy cattle and buffaloes The roughage level, particle size of roughage, fibre characteristics of the roughage are the important factors in maintaining animal productivity. Four combinations are given as an example for different levels of animal productivity (Table 3). In growing calves and lambs the roughage could constitute 40-60% of TMR, while in lactating animals the straw inclusion should be between 30-40% for high and medium yielding animals and 40-60% for low yielders. The increased intake and improved nutritive value of fibrous agricultural crop residues in TMR is due to mechanical processing attributed to particle size reduction.

Table 3. TMR formulations for cattle (For 100 kg feed)

S.No –Ingredient Type 1 Type 2 Type 3 Type 4

1 Maize/Sorghum/Bajra grains 10 –—–4——————– 5 ————-6

2 Groundnut/Soybean meal 15 ———15 ———–10 ————–6

3 De-oiled Sunflower cake 10———- 5 ————4 —————-5

4 Rice bran/DORB ———22 ———–23 ————-18 ———–10

5 Molasses————— 10——— 10 ————10 ————-10

6 Maize/wheat/jowar straw/dry grasses 30— 40 —-50 —-60

7 Mineral mixture 2—————– 2 ——————–2 ———2

8 Salt———————— 1 —————–1 ———-1 ————–1

Type 1 : For high producing dairy animals (more than 20 kg milk/day)

Type 2 and 3 : For medium producers, growing heifers and pregnant animals

Type 4 : For dry animals

Forage fibre characteristics and level in TMR

Several studies have shown that fibrous crop residues can be successfully used as a sole roughage source in the preparation of TMR for optimum growth and milk production (Reddy, 1988).The pattern of VFA production in the rumen and the animal performance is highly influenced by the characteristics and level of forage in TMR. Chewing activity dictates the rate and amount of saliva production which in turn is influenced by the source of roughage (Okine et al, 1997). Chewing activity is a good measure of the roughage characteristic and is related to the functioning of the rumen and fermentation activity. Dietary NDF is negatively associated with digestibility and dry matter intake which is associated with feed intake depression, chewing activity etc. It is observed that different forage sources with different NDF concentrations altered the nutrient supply and resulted in changes in milk composition. But the roughage source with different NDF concentrations had no effect on milk yield because the energy output from various substrates was similar among the sources of forage (Khorasani et al., 1993). Several scientists made an attempt to develop TMR using sunflower heads, lucerne hay (Mohan et al., 1997), corn gluten feed (Bernard et al., 1991), cotton seed hulls/stalks and sorghum straw (Reddy and Reddy, 1999), wheat straw (Singhal and Mudgal, 1980) etc. and reported the suitability of the crop residues as a source of roughage and improved nutrient utilization. The results opined that agro-industrial by-products used in the TMR preparation can be enriched by adding urea for effective utilization. Further, the inclusion of ammoniated wheat/jowar/bajra straw to the extent of 60% in TMR reported to be more economical in the diet of the buffaloes.

Particle size of roughage in TMR

Particle size reduction in forages results decreased chewing activity and depression in milk fat even the animals receives adequate NDF (Grant et al., 1990). Milk fat depression is a consequence of lowered forage to concentrate ratio in the diet or restricting the amount of forage fibre (Woodford et al., 1986). The minimum recommended NDF is 25-28 %, of which 75% should be supplied by forage. The extent to which particle size needs to be reduced for improving intake, for increasing density of feed, higher growth and maintaining milk fat level at the minimum processing costs are the important factors to be considered in processing TMR. Several studies reported variations in the particle size i.e. 12 mm sieve (1740 µ size) in sheep for cottonseed hulls (Reddy, 1990), 8 mm sieve in case of crossbred bulls for maize cobs (Murali et al, 1989) etc. The paddy straw ground by 8 mm sieve was optimum to be incorporated in TMR and reduced the cost of feeding compared to when ground at 12 mm and 16 mm sieves. In-sufficient particle size decreases the ruminal acetate to propionate ratio and the pH, which in turn lowers milk fat percentage. Reduced particle size increases dry matter intake, decreases digestibility and retention time of solids in the rumen (Martz and Belyea, 1986; Uden, 1987). This results in an increase in the fractional turnover rate of the ruminal dry matter and increased dry matter intake. Smaller forage particles spend less time in the rumen giving little scope for microbial digestion resulting in decreased fibre digestibility.

TMR versus separate feeding

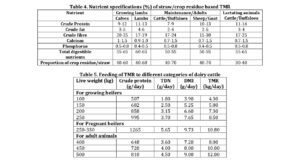

TMR feeding has been the most significant feature of dairy cattle feeding systems in the developed countries. The merits and demerits of this system have been summed up by Coppock et al. (1981). TMR comprising 45 % cotton straw, 47 % mixed grass hay or 35 % sunflower straw maintained milk production of 6-8 litres with normal fat content compared to conventional or individual feeding system (Reddy and Reddy, 1983). The merit of TMR is related to stable rumen environment for optimum rumen fermentation, minimal fermentation losses, minimal fluctuation in the release of ammonia and stabilization of acetate to propionate ratio, which favours normal fat synthesis and enhancement of low grade roughages (Sharma and Singhal, 1988). TMR has to be formulated to meet the nutrient requirements for the targeted functions i.e. Maintenance, Growth, Milk production (Table 4 and 5). The experiments indicated that incorporation of poor quality crop residues in TMR improved the voluntary feed intake, nutrient digestibilities, nutritive value and performance of various species of live stock in terms of growth, milk and meat production compared to conventional system of feeding.

Lactation and growth performance with TMR

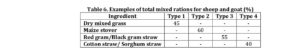

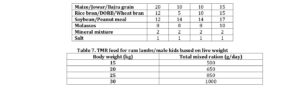

Several workers reported increased milk production in animals fed TMR compared to conventional method. This is because of the steady state of rumen environment conduce to continuous rumen function and digesta flow achieved by TMR feeding. Animals fed with TMR reported a trend for more milk and higher efficiency of use of metabolizable energy for milk production. Blending reduces the individual animal variation in feed consumption and results in better balance of nutrients than feeding the same ingredients individually (Holter et al., 1977). In on-farm trial increased milk production was reported in lactating Murrah buffaloes fed maize stover based TMR compared to conventional system of feeding (Raja Kishore et al., 2013). Number of studies has been reported regarding the impact of TMR on growth performance. Jaiprakash (1999) in buffalo calves fed wheat straw based TMR, Reddy and Reddy (1988) in crossbred calves fed wheat straw based TMR, Suresha et al. (2009) in goats fed red gram and bengal gram straw based TMR, Raja Kishore et al. (2014) in Nellore ram lambs fed black gram straw based TMR reported improved weight gain compared to conventional system of feeding. Formulation of TMR for sheep and goat Ram lamb rearing which is gaining importance in the recent years is best suited to feed lambs with TMR based on tree leaves, legume crop residues or hays and concentrate in the ration of 50:50 or 60:40 (R:C). In lambs fed TMR, an average daily gain (ADG) of 100-150g, finishing body weight of about 25-30 kg at 6- 9 months was reported. Several least cost rations based on TMR have been developed for economic production in sheep and goats (Table 6 and 7).

Cost economics in animals fed TMR

In the recent years TMR feeding is becoming increasingly popular. This system supports equal or even higher milk production in case of high yielding animals compared to conventional system with lower labour and feed costs. Further, TMR proved to be a best feed particularly in the ram lamb rearing maintained under intensive system. Several workers reported Decreased cost of feeding was reported in lactating Murrah Buffaloes fed TMR per kg 6 % fat corrected milk (FCM). The improvement in net benefit over feed cost was about 24 % due to feeding of complete ration over conventional system of feeding (Raja Kishore et al., 2013). The reports corroborated with the findings in lactating cross bred cows (Khan et al., 2010) fed TMR. Similarly, Chopade et al. (2010), Suresha et al. (2009) and Afzal et al. (2008) reported decreased cost of feed per kg live weight gain in kids, goats and sheep, respectively.

Advantages of TMR

- Provides balanced supply of feed to animals

- Reduction if feed wastage

- Effective utilization of agricultural crop residues

- Reduces environmental pollution and methane emission

- Best supporting feed during the times of natural calamities.

- TMR is cheaper, easy to transport and requires less space for storage.

- Provides steady supply in all seasons

- Improved animal health, productive and reproductive efficiency

- Better economic returns

- Huge scope of extended research on value addition.

TMR feeding tips

- Chopping of fodder should be given due importance as fine chopping had to be avoided and also grain particles also should not be so coarse. Silage or haylage should have a particle size of ¾ inch. · Dry matter intake of TMR should be given utmost importance. Low intake of dry matter should be checked and immediate action should be taken to correct the same. Large changes in the dry matter of forages affect the total dry matter of TMR and also intake by animals. · Groping of animals based on production not only improve the efficiency of TMR feeding but also reduce the feed cost because feeding of expensive ingredients to lower producing cows causes extensive loss to the farmer · In a big farm ideal grouping can be done as follows 1. Lactating animals – High, medium and low producing 2. Dry animals – Early and close to calving 3. Heifers – Pre and post breeding 4. Calves · The left off TMR not taken by the animals should be only 5%.

Source- Raja Kishore K*, Srinivas Kumar D and Raghava Rao E *Assistant Professor, Department of Animal Nutrition Sri Venkateswara Veterinary University NTR College of Veterinary Science, Gannavaram, AP-521 102, INDIA, https://bepls.com/