Effect of Lighting and Photoperiod on Broiler’s & Layer’s Production and Performance

Greenlight stimulates the growth of birds at an early age and switching to a different light color at 10 or 20 days of age may further stimulate growth.

The colour of light is a vital exogenous parameter and is now considered an important management tool in poultry production. Different colors have different effects on the performance of chickens depending on whether a given color of light is used continuously throughout the production cycle or alternated with other colors.

Generally, birds prefer to consume their feed under white light because it helps them identify texture differences that they cannot see under other colors. The feed intake response and growth performance of chickens reared under other light colors may not always be as good as with white light. Better results could be obtained, however, when light colors interact with other factors, such as light intensity and feed color. The choice of a lighting color system, therefore, should be made based on the intended production target or the production problem to be solved.

In some studies feed intake and growth performance were improved under blue or green lights provided at a high – rather than low – intensity. In other studies, an improvement was also obtained with red-dyed feed given under blue light, but no other combinations of light and feed colors have yet been examined.

Growth rate and carcass weight

Recent studies have examined an alternate lighting system in which the birds are exposed to one hour of light followed by three hours of darkness, with the cycle being repeated six times in a day. Shown in Table 3 are the results from broilers kept under the alternate or continuous lighting patterns. Although feed intake was reduced under the alternate lighting system, the birds here had better feed efficiency and greater body weights than the control group with continuous light. The improvement in performance was attributed to the birds resting during the dark period, thus lowering maintenance energy requirement and allowing more feed energy to be used for growth. It is also thought that feed is better utilised by birds after their digestive tracts are emptied during the periods of darkness.

The colour of lighting also affects feed utilisation and growth performance. Generally, birds prefer to consume feed under white light because it helps them identify texture differences they cannot see under different colours. In some cases, however, poultry producers may be prompted to use other light colours in order to alleviate a variety of production problems. Red light, for example, may be used for control of cannibalism, because birds cannot see the blood stimulant under red light. In other cases, blue or green lights may be used to keep birds calm by reducing hypothalamic gonadotropin production, and hence alleviate much of the losses caused by hyperactivity.

The feed intake response and growth performance of chickens reared under such light colours may not always be as good as with the white light. Better results could, however, be obtained when interacting colours of light with other factors such as light intensity and feed colour. In some studies, feed intake and growth performance were improved under blue or green lights provided at high- rather than low intensity. In other studies, improvement was also obtained with red-dyed feed given under blue light, but no other combinations of light and feed colours have yet been examined.

Greenlight stimulates the growth of birds at an early age and switching to a different light color at 10 or 20 days of age may further stimulate growth. It was recommended that shifting green light to blue and blue to green improved growth and performance in broilers. Birds raised under blue light had the highest carcass weight, while birds raised under green light had the lowest carcass weight. Birds raised under red and white light treatments showed similar carcass weights (see Table 1).

Behavioral problems

Blue or green light may be used to keep birds calm by reducing hypothalamic gonadotropin production and hence reducing hyperactivity, pecking damage, and energy costs, without compromising the welfare of the birds. In other cases, poultry producers may be prompted to use red light to control cannibalism because birds cannot see the blood stimulant under red light.

Red light, however, should not be used as the sole basis for alleviating cannibalism problems. Rather, other management and feeding strategies should also be adopted for better control; including beak trimming, lowering the brooding temperature, removal of severely injured birds, providing access to feed and water at all times, and balancing the diet appropriately for age and type of chickens reared, etc.

Immune response

Immune response data are presented in Table 2. The total NDV antibody titer showed the highest concentration in the alternative green-blue light group compared to other groups, while no difference was noted in the circulating thyroid hormones (T3) and (T4) among birds reared under different light colors. The increased concentration of NDV should protect from clinical Newcastle disease, although it may not prevent virus shedding from the trachea.

Hematological traits

Hematological measurements (red blood cells, white blood cells, hematocrit value, hemoglobin, and platelets) under different light treatments are shown in Table 3. An increase in the red blood cell count was seen under the yellow light treatment with a resulting increase in the hematocrit value that was ultimately reflected in a better growth response at 5 weeks of age compared to the other light treatments. The improved performance under the yellow color treatment may also be attributed to the higher platelet level found in this case, helping to improve the general condition of the bird by acting on digestion, destroying bacteria, increasing the secretion of chemicals that attract neutrophils and monocytes to sites of inflammation, as well as growth factors to maintain the lining of blood vessels.

Other management factors

Another study was conducted to examine the performance of chickens reared under 5 different color lighting schemes with 3 bird densities. It was shown that broilers reared under mixing blue-green light at the density of 12 bird/m2 had significant positive effects on growth performance compared to other lighting programs and bird densities (see Table 4). The reduced performance under high stocking density for each light color treatment, even with the blue-green light, may be attributed to the following factors:

- A general tendency toward a reduced growth rate with increasing stocking density, not only because of the reduced feed intake under such conditions but also because of the loss of feed energy due to immunological responses and other physiological adjustments. The reduced growth rate may further be attributed to the disruption in gut microflora that aids in digestion, the absorption of nutrients, and improvement of the intestinal micro-architecture.

- High stocking density affects the microbial profile of the litter with more toxins produced. Toxins affect the utilization of feed nutrients for growth and other biological functions.

- Increased stocking density leads to increased levels of airborne dust and hence more respiratory disease challenges which can lead to the incidence of other problems.

In these situations, the birds may not exhibit their full production potential, especially when reared under monochromatic light conditions. The same applies to other factors which can negatively affect performance, such as poor nutrition, an adverse microclimate, disease outbreaks, or inadequate biosecurity plans.

PHOTOPERIOD

Photoperiod is defined as the hours of light to which the birds are exposed in a period of 24 hours. It is very important in poultry farming, since the metabolic activity and, consequently, the productive parameters, as well as the appearance of certain alterations, will depend on it.

Through lighting, suitable biorhythms can be obtained, which will have an important impact on the regulation of water and feed consumption, on hormonal production, as well as on the distribution of animals in the shed and on the homogeneity of the batches.

Therefore, the implementation of lighting systems that optimize biorhythms and, consequently, cause an improvement in production parameters and a reduction in mortality and certain pathologies is essential.

HOW DOES LIGHT INFLUENCE INDUSTRIAL BROILER BREEDING?

Prolonged periods of illumination in the photoperiod provide birds with more time for feed intake and digestion, which speeds up metabolism and growth, a desired effect in industrial farming.

However, excessively prolonged periods of light excessively accelerate the metabolic rate, which can lead to cardiovascular problems, such as ascites, that consequently increase mortality rate and locomotor problems, among others.

- Cardiovascular problems

In extended light periods (long photoperiods), the metabolic rate increases and so does feed and water intake, which helps to accelerate fattening. In this case, requirements for high oxygen levels also raise up.

As a consequence, the cardiac output is increased and, sometimes, the physiological capacity of the animal to provide oxygen levels can be exceeded, causing ascites syndrome and mortality increase. Therefore, proper lighting management becomes important, so that, on the one hand, animals grow as fast as possible and, on the other, prevent a metabolic excess that leads to death due to ascites. For this, it is necessary to maintain lighting that favors growth, but also to restrict it the minimum necessary to avoid increased mortality and the appearance of other alterations.

- Musculoskeletal disorders

Due to the fast growth of the broilers, musculoskeletal disorders can appear, mainly in the legs, such as tibial dyschondroplasia. In order to reduce these problems, it is very important to adjust the photoperiod and reduce the number of hours with light, because, in the dark, growth is limited. In addition, it is shown that a reduction of the light hours of the photoperiod during weeks two and three of the cycle leads to a reduction in musculoskeletal disorders, although the mechanisms are not fully defined.

LIGHT PROGRAMS IN BROILERS

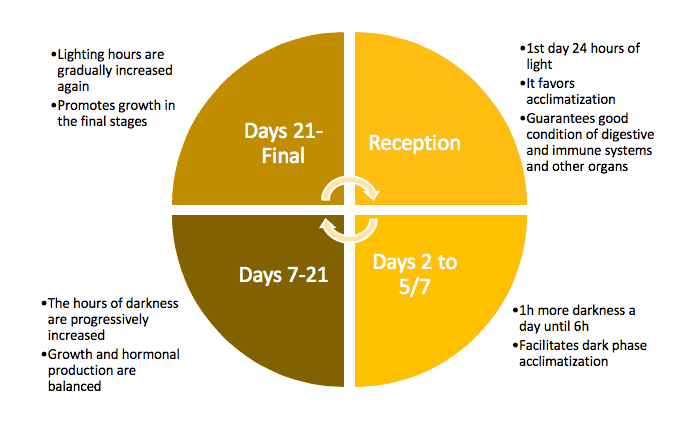

The most common is that, during the first days, birds are provided with continuous light. In this way, the cycle begins with 24-hour photoperiods of continuous illumination in the reception of the chicks, which stimulates feed and water intake and, consequently, a good start of the breeding is guaranteed along with a good development of the digestive and immune system, as well as other organs. On the second day, an hour of darkness is applied, so that birds start to get used to the dark phase of the photoperiod.

Between days 5 and 7, when the chicks quadruple the birth weight, the dark hours are increased to about 6 hours, and the dark phase is progressively increased until about the third week. Then, the lighting hours are increased progressively again to promote growth in the final stages.

FACTORS TO TAKE INTO ACCOUNT IN LIGHTING PROGRAMS

When implementing a lighting program, several factors must be considered, some of them are included in the different international regulations. For example, regulations mention aspects related to light intensity, which should be at least 20 lux in 80% of the farm surface, although it is more important not to exceed maximum levels, to avoid causing stress to the birds. The obligation to maintain certain hoursof darkness, approximately 4 to 6, is also regulated, although this time differs according to international regulations.

The most important of these factors are:

- Light intensity

Light intensity is an important factor, since a high intensity is related to a greater activity of the birds. This greater activity is desired in the reception and acclimatization of the chicks to the farm and facilitates the fattening the first days of life. Therefore, in this initial phase the light intensity should be higher, and it will be reduced in later periods, once the birds have been acclimatized, so that they are more static, with less movement, which promotes fattening in the growing phases.

- Colour

Traditionally, to implement the different photoperiod programs in industrial broiler breeding, white, warm or cold light has been used. However, there are studies that show that green and blue spectra favor the fattening of birds, as well as immunity. Although, the color of the light in broiler chicken is not as important as in layers, where the red spectrum light produces an important hormonal stimulation that induces a higher egg production.

- Distribution

It is very important that the lighting systems are well distributed, so that the light reaches all parts of the shed. This avoids grouping of the birds in certain areas of the farm and competition for feeders and drinkers, which affects growth and homogeneity of the batches, as well as predisposes to the appearance of pathologies or locomotor disorders.

TYPES OF LIGHTING SYSTEMS

There are many types of lighting systems for poultry farms, all of them aimed at maintaining the lighting programs determined by the technician responsible for the farm.

There are different types of lamps such as incandescent, discharge or LED type, among others. All of them have different advantages and disadvantages, but the choice of one or another will depend on the availability and the decision of the technician, which should always be aimed at maintaining a homogeneous distribution of the lighting, as well as the intensity and spectrum required in each phase or each type of production.

For this, not only the type of equipment or lamps must be taken into account, but also the design and layout (the distance between the points of light and to the walls, the height, the number of lighting lines) and the characteristics for each phase, such as the spectrum or the intensity.

LIGHT PROGRAMS IN LAYERS

Role of light on egg production

The egg production is associated with the length and intensity of the light received by the bird daily. Light stimulates the anterior lobe of the pituitary gland through optic nerve for the release of FSH and LH. Light energy also penetrates through the skull, skin and feathers. FSH increases the growth of the ovarian follicles. Upon reaching maturity, the ovum is released by the action of LH.

Important points regarding light

- Wavelength between 400 and 700 millimicrons (nanometer) ® Visible to eye

- The longer wavelengths (Red) of visible light are more capable of reaching the brain than shorter wavelengths.

- The intensity of sun’s light rays varied due to

-

- Position of the sun

- Cloudiness

- Dust and moisture in the air

-

- Length of day light varies ® due to the relative position of the earth to the sun

- In Northern Hemisphere,

-

- June 21st ® Longest day of the year

- December 21st ® Shortest day of the year

- (In southern hemisphere it is reversed)

-

- Day light occurs from 15 to 30 minutes before sunrise and darkness occurs 15 to 30 minutes after sunset is due to the curvature of earth’s surface and thus the length of light day is somewhat longer than the hours between sunrise and sunset. But the time between sunrise and sunset is usually considered as the “light day”

Light management

The manner in which lights are installed in the poultry house has a role on their efficiency. Some of the important points regarding fixing bulbs in poultry houses are,

- The distance between bulbs should be 1½ times the distance from the bulb to the bird level.

- The distance from the bulbs to the outer edges of the house should be only ½ the distance between bulbs.

- In cage system, the bulbs should be placed in such a way that their rays fall on the feed and on the birds.

- Clean reflectors increase the light intensity at bird level by 50%, compared with no reflector.

- Avoid cone shape reflectors since they confine the light rays to limited area. Better to use flat type reflector with rounded edge.

- In case of deep litter system, the bulb is to be placed at 7-8’ height whereas in cage house, keep in aisle.

- Avoid hanging bulbs by a cord in open houses

- Very dirty bulbs emit about 1/3 less light than clean bulbs.

- Light bulbs should be cleaned once in two weeks.

Light effects during growing period

Decreasing the length of light day during growing period will lead to

- Increase the age at sexual maturity

- Increase the number of eggs laid during the first half of the egg production (but not in total number of eggs laid)

- Increase the size of the first eggs produced.

Light restriction alone delays the sexual maturity at the maximum of 3 weeks. If feed restriction is combined with light restriction we can delay up to 4 weeks period.

Light effects during laying period

Birds reared under increased day-light produce more eggs due to the release of FSH and LH from the pituitary. Brightness of light also has influence on egg production. On practical conditions, 1 ft candle light intensity is needed in layer houses. In multi-duck cage system, minimum of 0.5 foot candle light intensity is needed at the lower deck. For maximum egg production, 16 hours light is needed during peak egg production period. Reducing photoperiod during laying period seriously affects egg production. The artificial light can be given either in the morning, evening or both morning and evening.

Combination growing-laying light programs

Two important points to be consider regarding lighting are,

- The length of the light day should never increase for growing pullets.

- The length of the light day should never decrease for laying pullets.

In-season flocks

Those birds grown during a period when the length of the natural light day is decreasing, at least during the last part of their growing cycle are called in-season flocks. As a general rule, chicks hatched between March 1st and August 31st in the Northern Hemisphere is called in-season flocks.

Out-season flocks

Chicks hatched between September 1st and February 28th are called out-season flocks since their growing period falls on increasing light-day.

Instructions for growing and laying light programs in open-sided houses

a) In-season flock

No artificial light is needed up to 20 weeks (in case of meat-type breeders 22 weeks). At 20 weeks of age increase the light to 13 hours. Then add 1 hr per week until it attains 16 hours light.

b) Out-season flock

Two methods can be adopted

i) Constant light-day program

Determine the length of the longest natural light day before the pullets reach 20 weeks of age. Maintain this period of daily light hours from the 3rd day until 20 weeks by supplementing artificial light with natural light. Then increase 1 hour of light at this stage and increase 1 hour every week until it reaches 16 hours total light period.

ii) Decreasing day-light program

Determine the total natural day-light hours when the pullets reach 20 weeks of age. Then add 7 hours. This represents the length of the light day from the 3rd day. Thereafter reduce the length of light day by 20 minutes per week. At 20 weeks of age increase the length of the light day by 1 hour. Then increase 1 hour per week until it attains 16 hours light per day.

Photo-refractoriness

Photo-refractoriness is a condition in which the bird is not capable of responding to long day lengths. Greater the stimulatory day length, the sooner and more pronounced the reduction in egg production due to photo-refractoriness.

Ahemeral lighting programs

When the total period of light and dark not equals 24 hours we can call it as ahemeral lighting cycle. There are two types: Longer day (14 hr light + 14 hr dark) and shorter day (11 hr light + 11 hr dark). Longer day cycle increases egg shell quality where as, shorter day cycle increases the egg production by 2%. However, these cycles are not compatible with normal working schedule and needs light proof houses.

CONCLUSIONS

The photoperiod is very important in poultry industry because it has a direct effect on birds’ metabolic activity, the productive parameters and the appearance of certain, which depend on the hours of light and its intensity. It is, therefore, essential to design a lighting program that balances the activity of birds and the hormonal production, in order to optimize the level of production and minimize the possible arising problems. The responsible technician must take into account the different characteristics of the lighting equipment in order to implement a system that achieves adequate lighting times, intensity, spectrum and distribution for each phase and type of production.

DR SURINDER KHANNA,PUNJAB

References are available on request.