Decontamination of Egg shells using UV light- A Promising Technique

Eggs are a staple in many diets worldwide, providing a rich source of protein and essential nutrients. However, concerns about food safety have led to the exploration of innovative methods for decontaminating eggshells and ensuring the quality and safety of eggs for consumers. One such promising technique is the use of ultraviolet (UV) light for the decontamination of eggshells. In this article, we will explore the rationale behind using UV light, the process involved, and the potential benefits of this technique in enhancing food safety.

Poultry is one of the fastest growing segments of the agricultural sector in India today. India is now the world’s fifth largest egg producer and the eighteenth largest broilers producer. Eggs are an important and well-balanced source of essential nutrients. Egg yolks and whole eggs are a good source of protein and choline. Poor egg shell quality is a huge hidden cost to the egg producer. Estimates are that more than 10% of eggs produced in the hen house are uncollectible or break before intended use. The economic losses for the breeders will be even more due to reduced hatchability and chick livability.

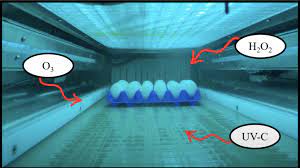

Therefore, every effort must be directed towards improving shell quality and reducing egg shell contamination. Decontamination of egg shells is required to improve the microbiological safety of the fresh hen eggs used for human consumption or for hatching. Conventional chemical decontamination methods involving quaternary ammonium disinfectant, sodium hydroxide, phenol, hydrogen peroxide or formaldehyde, leave residues on egg shells that may damage the cuticle layer. Therefore, new techniques of egg shells decontamination, such as ultraviolet (UV) radiation, have been developed. Hence, the treatment with UV light has a competitive advantage in comparison with traditional egg shell sanitation treatments for decontamination.

Principles of UV light treatment

UV light is emitted by electric arcs and specialized lights such as mercury lamps and black light systems. These systems are designed to produce UV light with a specific wavelength range, in accordance with the proposed use. The range of UV wavelength is between 10 nm and 400 nm. Ultraviolet (UV) light is the unique technology. UV-light is electromagnetic radiation in the spectral region classified into the following wavelength ranges: UVA (315-400 nm) are normally responsible for changes in melanin human skin called tanning, UV-B (280-315 nm) light is absorbed by the ozone layer in proportion of around 97%. A small portion of the light reaches the surface of the earth and may cause damage to the living microorganisms, UVC (200-280 nm), and Vacuum-UV (100 nm-200nm) (International Ultraviolet Association, 2009). UV-C light possesses germicidal properties. It deactivates the DNA of bacteria, viruses, and other pathogens and, thus, destroys their ability to multiply and cause disease.

Advantages of UV light treatment

The importance of eggs for human consumption and hatching in conjunction with the high susceptibility of microbial contamination has led to the necessity of egg shell sanitation. Chemical sanitizers are prone to damage eggs cuticle layers and besides limited effectiveness in reducing pathogens the residues it could represent a chemical hazards to food safety.

To avoid these negative aspects, new non- destructive, non- thermal methods were investigated

1. UV light treatment achieved significantly greater reductions in bacterial population of clean and recently contaminated egg shells compared with methods in which chemical sanitizers were used

2. UV light treatment ensured significant reductions of Salmonella spp., the most frequently present pathogen reported in eggs

3. UV light treatment facilitates the hygiene control of the transportation system and enables rollers decontamination

4. It also allow elimination of microorganisms could be achieved at low temperatures and under relative dry conditions

5. UV light has at high intensities and low time periods has the potential to reduce APC of the egg shells

6. S. typhimurium treated with UV light on egg shells did not recover after subsequent incubation under dark or light conditions

7. UV light treatment of hatching eggs in a prototype cabinet can effectively reduce the aerobic and pathogenic bacteria on the eggshells without affecting either egg shell conductance or eggs hatchability

8. Salmonella was effectively inactivated on egg shells in a short time and at low temperature with the use of a combination of UV light and ozone treatment.

There are two basic methods of UV-light treatment:

continuous UV light and pulsed UV-light. Continuous UV-light works with a mercury lamp which emits monochromatic light (XENON, 2005). This method requires long duration of exposure to UV light in order to ensure sufficient treatment.

- UV light inactivation of microorganisms on egg shell

UV light is lethal to most microorganisms found in air, water or on hard surfaces. Cell inactivation is based on the damage of nucleic acids (DNA and RNA) under UV light. Nucleic acids absorb UV light from 200 to 310 nm. Absorbed UV light causes the breaking of some bonds and the formation of pyrimidine dimers, which are bonded to the adjacent pairs of thyamine or cytosine pyrimidines on the same RNA or DNA strand. These dimers prevent cells from replicating, so microorganisms become inactive and unable to proliferate (Koutchma et al., 2009).Exposing egg shells to a UV-C light intensity of 1.72mW/ cm2 whilst rotating the eggs at one revolution per min resulted in aerobic bacteria, yeast and mould populations being significantly reduced.

2. Pulsed UV-light -Pulsed UV-light is a novel technology which is more efficient and faster than conventional continuous UV-light method (Bialka, 2006). Pulsed UV-light is generated by a xenon gas lamp by using a modest energy input that can yield high peak power dissipation. The pulsed light lamp generates a continuum broadband spectrum from deep UV to the infrared, which is rich and efficient in the UV range (Demirci and Panico, 2008). The pulsed light flashes are created by compressing electrical energy into short pulses, which energize an inert Xenon gas lamp. The lamp emits an intense flash of light with duration of a few hundred microseconds. Various studies have shown that this new technology can eliminate pathogenic and spoilage microorganisms on raw and minimally-processed foods such as egg shells. In 1999, FDA approved pulsed light treatment of foods (Federal Register, 1999). Pulsed UV-light is a non-chemical method and considered to be non-thermal for short treatment times. In addition, this novel technology can be an alternative to irradiation, which may cause ionization of small molecules in food components due to the very short wavelength (Dunn et al., 1995). Ionization of the molecules may introduce some chemical changes in the food. Since, UV-light does not involve very short wavelength ranges, it is not considered to cause ionization. Various researchers have investigated the effectiveness of pulsed light on the microbial loads of foods. Dunn (1996) studied the application of pulsed light to foods and eggs. The UV light and pulsed light processing is a new concept and has many applications in the food industry as a non-thermal technique of egg shell preservation. While developing the applications of pulsed light processing, it is to be taken into consideration that the food to be processed, the microbial type and load.

Rationale for UV Light Decontamination

- Microbial Contamination

Eggshells are susceptible to microbial contamination, primarily from bacteria such as Salmonella and Escherichia coli (E. coli). Contamination can occur during the laying process or through environmental exposure.

- Current Decontamination Methods

Conventional methods of eggshell decontamination include washing with detergents or chemical sanitizers. However, these methods may have limitations, including the potential for residue formation and incomplete removal of pathogens.

- UV Light as a Non-Chemical Alternative

UV light, specifically in the germicidal range (UV-C, 200-280 nm), has demonstrated antimicrobial properties. UV-C light can effectively inactivate bacteria, viruses, and other microorganisms, providing a non-chemical alternative for decontamination.

UV Light Decontamination Process

- UV-C Irradiation

The decontamination process involves exposing eggshells to UV-C light. UV-C light has the ability to disrupt the DNA and RNA of microorganisms, rendering them unable to replicate and causing their inactivation.

- Optimal Exposure Time

The effectiveness of UV-C decontamination is influenced by factors such as UV light intensity, exposure time, and the distance between the light source and the eggshell surface. Optimal conditions must be determined to achieve maximum microbial reduction without affecting egg quality.

- Post-Irradiation Handling

After UV-C irradiation, proper handling and storage of eggs are crucial. Measures should be in place to prevent recontamination during subsequent processing, packaging, and transportation.

Potential Benefits of UV Light Decontamination

- Pathogen Reduction

UV light has demonstrated efficacy in reducing or eliminating common pathogens found on eggshells, including Salmonella and E. coli. This can contribute to enhanced food safety.

- Preservation of Egg Quality

Compared to some chemical decontamination methods, UV light has the advantage of not leaving chemical residues on the eggshell. This helps in preserving the natural quality and characteristics of eggs.

- Environmentally Friendly

UV light decontamination is a more environmentally friendly option as it does not involve the use of chemical sanitizers that may have environmental implications.

- Potential for Automation

UV light decontamination processes can be integrated into automated egg processing lines, allowing for efficient and continuous decontamination without significant disruption to production.

Challenges and Considerations

- Uniform Exposure

Ensuring uniform exposure of all egg surfaces to UV light is crucial for effective decontamination. The design of UV-C irradiation systems must account for the curvature and irregularities of eggshells.

- Eggshell Characteristics

The composition and thickness of eggshells can vary among different egg types (e.g., chicken, duck, quail). Research is ongoing to determine the optimal UV-C exposure parameters for various eggshell characteristics.

- Regulatory Approval

While UV light decontamination shows promise, regulatory approval and standardization are essential to establish guidelines and ensure the safety and efficacy of this technique for large-scale egg production.

Conclusion

Decontamination of eggshells using UV light represents a promising and innovative technique for enhancing food safety in the poultry industry. As consumer awareness and concerns about foodborne illnesses continue to grow, adopting effective decontamination methods becomes imperative. UV light offers a non-chemical, environmentally friendly solution that, when properly optimized and integrated into existing egg processing systems, has the potential to reduce microbial contamination and contribute to safer and higher-quality eggs for consumers. Ongoing research, technological advancements, and collaboration between industry stakeholders and regulatory bodies will play a crucial role in establishing UV light decontamination as a standard practice in the egg production process.

Compiled & Shared by- This paper is a compilation of groupwork provided by the

Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.