ROLE OF POULTRY DRINKING WATER SANITATION IN POULTRY FARMING

Introduction.

Water is the most essential nutrient for poultry and livestock. Birds consume more water than feed. Water is involved virtually in every physiological process. Water is a medium for transporting nutrients and food along the gastrointestinal tract. Water plays an important role in regulating body temperature and is a component of many basic chemical reactions. Unfortunately, Water is the one ingredient that does not always receive the attention that it deserves.

In modern day poultry production water should be provided as clean as possible in order to avoid the contamination with microorganisms. Good quality water is very important for good digestion and to create a healthy gut flora, which will help the bird to absorb all the essential nutrients. Water quality management is very important to guarantee broiler performance. Constant monitoring is required and not only when problems are observed. It is recommended that water samples be collected quarterly and for a very reasonable cost can be sent to the Laboratories for analyses. The information gained from these analyses including your pH, ORP and chlorine level readings can be used to determine the best management practices required for your specific water conditions.

Profitability in poultry production can only be optimized when everything goes right, and that includes keeping the birds healthy. Hygienic Water supply system is one of the most important key factors for good health and growth of poultry. It is important for water to remain hygienic all the way until it reaches the birds, and so water & drinker lines hygiene must be a focus of attention for the farm.

Water lines should be thoroughly cleaned and sanitized at regular intervals.

1. Adjust drinkers to correct height

2. Fix leaks

3. Look out for air locks

4. Install a filter to prevent sediment build-up

5. Prevent bio-film by flushing ~ immediately after any intervention of medication ~ one minute for every 30 meters of pipe length ~ at least once a week ~ more than once a day during warm weather ~ use high pressure (1.5-3.0 bars)

6. Use high quality acidifier in water for desired pH level Water source get contaminated with various organic and inorganic substances resulting in high pH thus chances of growing pathogens including salmonella sp., E. coli and fungi is high. Contamination of drinking water in poultry is formidable. Generally it is recommended that optimum pH of drinking water of poultry should be around 4.5 to 5.5 and B value of feed should be low to maintain normal gastric pH of birds. Since gastric pH is higher in chicks than in growers and adult birds, an utmost care should be taken during brooding period of chicks for Reducing chick mortality . Controlling E. coli, Salmonella and fungi , Improving FCR and weight gain ,Reducing ammonia in litter ,Reducing moisture in litter.

To take care of the routine problems of poultry farm, we add sanitizers, acidifiers, medications, nutritional supplements & vaccines etc without understanding chemical interaction into the water which itself comes carrying its own baggage of organic & inorganic material. We will have to keep in mind that while some chemical interaction could be synergistic, actually helping one another to work better but in the mean time making wrong solution may create problem by reducing effectiveness of the additives and some time leading to hazardous effect to birds & environment.

Following are some action & interactions which we must understand while preparing drinking water to poultry:-—–

☞ Hydrogen peroxide (H₂O₂) and Chlorine (Cl) are not compatible so should not be used at the same time. Both are oxidizer and they will turn on each other.

☞ Copper sulfate is not compatible with Chlorine (Cl) however Copper sulfate which is an antimicrobial & antifungal agent actually enhances the effectiveness of H₂O₂ so they can be run at the same time with separate medicators.

☞ Organic iodine (Not the inorganic) is very compatible with Chlorine. This combination can help to prevent a full-blown respiratory infection if it is used early enough to treat sniffing, a loose croupy cough.

☞ Iodine, like Chlorine, works better at a lower pH.

☞ Chlorine is not compatible with any compound that act as reducing agent which would include most minerals water additives. For example, products that contain copper, sulfur or iron will tie up the Chlorine and make it unavailable to work effectively as a sanitizer.

☞ Antibiotic like Chlortetracycline & tetracycline works best in low pH range. If you have alkaline water, adding good acidifier liquid actually enhances absorption of these products. But product like Penicillin & Sulpha drugs works better in pH above 7 so turning off the water acidifier during medication with penicillin & sulpha group is recommended.

☞ Vaccines are typically protein so at any time vaccines are used in water, the water pH should be above 4.

☞ All sanitizers lose efficacy at colder water temperatures. Chlorine, chlorine dioxide & peroxide/ozone are all temperature sensitive so colder water will slow down their reaction time.

☞ Peroxide is strong oxidant and contact with personnel is extremely dangerous. Peroxide deteriorates gradually even when stored correctly.

☞ There would be slime blooms in water system after the use of antibiotics. The antibiotic disrupts the microbial population in waterline system just as it does in the GI tract, allowing microbes such as yeast & mould to grow undisturbed. So, thorough cleaning of water pipeline system to remove the slime using 3% hydrogen peroxide solution with high pressure flushing water routinely is recommended as & when required.

Regular use of best quality acidifier in fresh drinking water of poultry farm will solve routine problems but it should have following traits: —

It Should be stable in all pH ranges. Make sure that you are using perfect hygienic water for your birds and

• Must work in fore gut as well as in hind gut

• Must suppress bacteria that are “pH sensitive” like E.coli, Salmonella, Campylobacter, C. perfringens, Listeria etc.

•assimilation. not a complicated solution.

Water quality frequently changes from season to season in each location or area depending on the source. In India, water obtained from wells generally contains high levels of minerals leading to high water alkalinity and hardness. Several water samples obtained across the states from broiler farms experiencing flock performance problems additionally contained high levels of sodium, potassium and iron.

Sanitation and acidification are the practices that most growers implement to improve water quality for their broilers. It is important to understand that these are two different approaches that work together to improve water quality; however, one does not replace the other. Acidifiers alone cannot replace sanitizers that effectively reduce microbial loads of heavily contaminated water sources. To obtain an effective sanitation with chlorine requires that the water pH be between 6.0 and 7.0. Consequently, acidifiers should be applied to water with pH readings higher than 7.5, which is also associated with high alkalinity.

The acid and chlorine should never be mixed together to create stock solutions, since these chemicals react and release dangerous gases. An inline pump with dual injectors can be used to add the acidifier stock solutions prior to the addition of the chlorine solution. Chlorine is not the only available sanitizer. Ozone, chlorine dioxide, hydrogen peroxide and iodine are also used in poultry production with excellent results.

Water sanitation starts with a regular pipeline cleaning program to reduce the natural build-up of minerals, algae, molds, viruses and bacteria that are capable of forming bio-films. Daily water sanitation may not work when strong bio-films are established in the water lines. Citric acid, sodium hypochlorite, and quaternary ammonium compounds are some of the products used to clean water lines. Water lines can also be effectively cleaned by adding a 50% solution of hydrogen peroxide to the medicators to obtain a 1% solution in the pipeline and allowed to soak overnight. Independent of the product used to destroy the biofilm, it is important to completely flush out the dissolved materials. This material contains high levels of minerals, toxins produced by dead bacteria, algae, and free microorganisms that can be even more harmful for the new flock.

Acidifiers are used to keep water pH to less than 7.0 and help to reduce bacteria proliferation. It is common that acidifiers are added to drinking water of broilers for short intervals of one to three days at a time. However, in farms where the water pH is higher than 8.0, those days without pH control can negatively affect the efficacy of water sanitation. It is true that chickens can rapidly adapt to acid water (pH 3, 4, or 5), but constant drastic changes may affect their patterns of water and feed consumption and lead to sub-clinical intestinal problems.

It has been observed that lowering pH to less than 5.0 does not provide significant improvements in broiler performance. Overuse of organic acids such as citric and acetic acids can lead to reductions in water and feed consumption and lead to a depression in growth rate. This detrimental effect of excess acid is due to the strong taste that acids can give to water. Due to the natural buffering capacity of water and the interactions with minerals, it is recommended that producers monitor the pH of drinking water when using acidifiers at the manufacturer’s recommended levels.

Microbial Growth

Factors, which influence the growth of the microorganisms, are the water activity, pH, temperature and the nutrients.

Water activity is the most important factor for the growth of pathogenic microorganism such as E.coli, Salmonella, and Campylobacter. The pathogenic microorganisms requires a water activity of > 0.9 which is found in the drinking water.

The effect of pH on microbial growth

The hydrogen ion concentration in water determines the pH level and is very critical for microbial growth. Salmonella, E.coli and Campylobacter can survive in a pH range 4.5 to 8 with an optimum pH for growth around 7. The drinking water pH ranges between, 6.5 to 8 are favourable for the growth and multiplication of the pathogenic microorganisms.

Temperature is the important factor, which can influence the microbial growth of microorganisms. The microorganisms can survive and grow better at an optimum temperature of 370 C.

The Pathogenic microorganisms can rapidly grow and multiply in the presence of combination of favourable factors like, water activity, pH, temperature and the nutrients from the feed and manure.

Maintaining drinking water quality for poultry is an important nutritional aspect as birds consume water at twice the level of feed. One prime factor that determines the wholesomeness of water is its microbial quality. Therefore, it should be of primary concern for production personnel and poultry producers to know the microbial quality of water supplies provided to their birds and confirm if it is within the acceptable range. Various researches indicate that water supplies are much vulnerable to microbial contamination and this is true even with the farms with good management system. Furthermore, water sources such as wells or reservoirs are dynamic with water quality changing as often season to season. Establishing routine testing of supplies and taking corrective action when necessary can have a significant impact on optimizing flock performance.

1- Taking swab sample to examine waterline s sanitation, 2- Taking drip sample to examine drinking water quality.

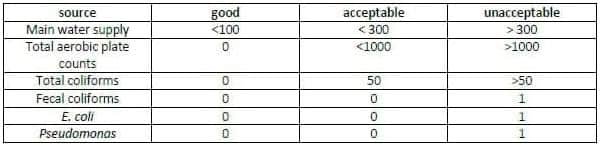

Microbial Water Quality Standards for Poultry Drinking Water.—

Water is presumed safe if it has a zero microbial population, provided that mineral content is at safe levels and undesired contaminants are not present. However, presence of microbes in water is not always correlated with a disease in flocks unless it increases above a certain infectious level. The following table gives the acceptable levels of bacteria in colony forming units (cfu) per milliliter (ml) in drinking water for poultry operation.

Microbial contamination above the acceptable levels in drinking water directly affects health and performance.

Water supplied to birds should be within the acceptable microbial load.

Water Sanitation Options. —-

Water disinfection is the usual water treatment used in bird rearing. The aim is to eliminate pathogens that might be in the water, both those originated from contamination of the water source and those incorporated in the way between the water source and the drinkers. A second objective is to leave residual levels of chlorine in the water in order to eliminate pathogens that might be added to it if infected birds have access to water in the drinkers

The goal of poultry water sanitation procedures and sanitizer/disinfectant products is to target microbial challenges that exist and thrive in water supplies whether they are bacterial, fungal, viral or protozoal. An ideal disinfectant used as a drinking water sanitizer should create disinfectant residual throughout the distribution system and should inactivate microbes, control biofilms or neutralize undesired contaminants.

Of the limited water sanitation options available in poultry operation, some common practices are discussed below.

1. Chlorination.—

Chlorination has been a highly accepted method in water disinfection both for human and animal drinking purpose for many years. It involves adding chlorine to water and can be performed using chlorine containing compounds. In poultry operations, the commonly used chlorine sources for poultry drinking water sanitation are sodium hypochlorite, elemental chlorine gas and calcium hypochlorite. Their presence in the optimal pH range will create hypochlorous acid on hydrolysis.

Cl2 (g) +H2O=> HOCl + H+Cl-

NaOCl +H2O =>HOCl + Na+ + OH-

Ca(OCl)2 + H2O =>Ca(OH)2 + 2HOCl

Hypochlorous acid has a strong germicidal action. However, in high pH conditions (>8.5 pH), it dissociates completely into hypochlorite ions which has a less germicidal action than the hypochlorous acid. The pH range between 6.5 and 8 .5 has incomplete dissociation, while pH below 6.5 has no or a negligible dissociation of the hypochlorous form.

HOCl <=> H+ + O Cl-

Therefore, chlorination is more effective at lower pH levels and often drinking water is acidified to support chlorine disinfectant efficacy for improved sanitizing residual which supports better bird performance. However, careful selection among various acid products available is necessary to avoid water consumption impacts. When using chlorine and acidifiers together in water, they should be mixed and injected separately to avoid poisonous gas formation.

When drinking water has 2-5 ppm free chlorine residual, it is effective against most microbial growth in water. E. coli O157:H7, most Salmonella and Campylobacter species, and avian flu virus are easily inactivated at these residual levels or at even lower levels. Disinfectant residual levels required for the microbial inactivation are governed by other water quality parameters as well.

An appropriate application strategy of chlorine in drinking water on poultry farms help reduce the microbial load and also minimize the biofilm buildup in water systems. One study conducted in U of Arkansas in 2012 showed that after line cleaning to minimal biofilm levels, daily drinking water disinfection providing free chlorine residual levels of 0.5 to 1 ppm when birds drink helps keep the microbial loads within the acceptable range of > 1000 cfu/ml throughout the flock period. At this residual level, however, biofilm formation does reoccur by the end of flock grow out period (6th week) requiring a mandatory line cleaning between flocks to ensure safe drinking water for the next flock of chicks.

Chlorine products have been the primary water disinfectant products for thirty-forty years in the poultry industry. Unfortunately, microbes are becoming resistant to these products because they have not been always used properly. Therefore, the industry also needs to identify other options of water sanitation and have clear guidelines on the efficacy of alternative disinfectants, as well as their optimal usage levels.

2. Hydrogen Peroxide: An alternative disinfectant to Chlorine.—–

Recent field experiences have shown that poor performing farms are greatly benefitted from water sanitation programs using hydrogen peroxide which is an alternative disinfectant to chlorine. Hydrogen peroxide has a rapid bactericidal action and is effective against a wide range of viruses, yeast, and fungi. Pseudomonas aeruginosa, Escherichia coli, Salmonella typhimurium, Staphylococcus aureus, Aspergillus fumigates and Fusarium species are well inactivated even in presence of organic matter. Hydrogen peroxide inactivates microbes creating oxidative stress by forming very strong oxidizing agents, hydroxyl radicals, from superoxide (O2.-) radicals, and readily oxidizes the proteins and microbial enzymes; however, efficacy differs between liquid and gaseous forms.

O 2.− + H2O2 =>O2 + OH− + OH.

Maintaining 25-50 ppm of hydrogen peroxide residuals in the water is considered the effective for limiting most microbial growth.

In market, both the stabilized and non-stabilized forms of hyrdrogen peroxide products are available. Studies conducted in U of Arkansas demonstrate stabilized hydrogen peroxide products in market hold higher concentrations of residuals for a longer time than non-stabilized. Heavy metal ions used as stabilizers like silver and copper, and organic acids like peracetic and ascorbic acid in hydrogen peroxide helps in synergize the disinfecting property of hydrogen peroxide and is effective against heavily contaminated water as well.

Successful cleaning of poultry waterlines with hydrogen peroxide products with minimal equipment damage can also be done. Bacterial biofilms such as Pseudomonas aeroginosa and Listeria monocytogenes and viral biofilm such as Infectious Laryngotracheitis (ILT) virus are effectively cleaned using hydrogen peroxide disinfectant.

3. Other Water Sanitizers in Poultry Operation.——-

Another successfully used water disinfectant for sanitizing poultry drinking water is chlorine dioxide. It acts as a selective oxidant as it has a single electron transfer mechanism and reduces to form chlorite ion which exists as the dominant species in water.

ClO2(aq) + e- => ClO2-

If the water is dirty or has a significant organic load, then disinfecting with chlorine requires higher free residuals of chlorine thus impacting taste and odor. Sanitizing with chlorine dioxide is a good option because its use in similar water supplies does not cause the taste or odor issues. Chlorine dioxide kills bacteria and viruses similar to or better than chlorine and is unaffected by a wide pH range.

Other disinfectants like quaternary ammonium compounds and iodophores are also used in poultry operation for disinfecting water and water system. Ozone and UV rays can also be used for water sanitation but not common in poultry practices. Advance Oxidation Processes that involves creating hydroxyl ions as disinfecting molecules during disinfection procedure have been also introduced recently in the industry.

As oxidizing agents are generally used during water disinfection, Oxidation Reduction Potential (ORP) values give the oxidizing ability of the chemicals in water to oxidize/kill microbes. The ORP values are affected by concentration of oxidizing residuals and are pH dependent and 650mV or above in water are considered enough to destroy most bacteria and viruses within few seconds. Added benefit of oxidizing agents in water includes its secondary function in oxidizing iron and manganese that minimizes drinker coagulation.

Conclusions.

The poultry industry uses various water sources such as the municipal water, underground water, and to some extent, surface water and rain water. Regardless of the source, it is highly important that water provided should be free of microbial contamination to ensure flock health and performance, and food safety. Therefore, water sanitation is a very crucial step in a poultry operation and should be effectively carried out.

Various brands of water sanitizers or water line cleaners are available in the market under a few classes of disinfectants advocating its efficacy under worst case conditions. These products are required to monitor in field conditions for their true efficacy, applicability, and cost effectiveness along with safety aspects. Water being the prime nutrient for poultry, the industry should pay close attention in these regards to providing the best sanitizing option for poultry producers and to address any type of water quality issues.

DRINKING WATER SANITATION IN POULTRY FARMING

DRINKING WATER SANITATION IN POULTRY FARMING

Reference: On request.

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.