An Economic Nanoparticle Assisted Chlorhexidine Delivery System to Mitigate Biofilms in Conventional Livestock Farms of Assam to Achieve One Health and Safeguard Food Safety & Security.

- Kanjanabh Kumar Das, 4th Year B.V.Sc. & A.H.

- Tridisha Das, 4th Year B.V.Sc. & A.H.

- Nayandeep Kalita, 2nd Year M.V.Sc.

BACKGROUND:

Microbes are biological entities that constitute the microbiological world around us. These entities, an important area of study since their discovery by Leeuwenhoek, were earlier regarded as demonic curses to diseases. Throughout the advancement of veterinary and medical sciences, scientists have been isolating these microbes, especially bacteria, in pure cultures. These allowed us to have a great understanding of their existence and demise, spearheading the design of meticulous antimicrobials.

Unlike lab cultures, microbes are often found as complex tenacious associations with similar or dissimilar organisms on environmental surfaces, which were later nomenclatured as biofilms. This phenomenon was later explained as the ‘Bottle Effect’ in 1940 – ‘the enhancement of bacterial growth when attached to a surface’. Thus, biofilms were defined as “microbial cells immobilised in a matrix of extracellular polymers (EPS) acting as an independent functioning ecosystem regulated homeostatically” (Percival et al. 2011). The resistance of the biofilm against various antimicrobials and conventional disinfectants such as chlorhexidine is assignable to the EPS (Extracellular Polymeric Substances) layer, which is mostly composed of polysaccharides, proteins and other biomolecules. These single-species or multi-species associations have posed a significant threat to the concept of ‘One Health’, and have contributed to the pressing issue of Antimicrobial Resistance (AMR).

Milk and milk products are an essential part of the nation’s diet, with India accounting for 22% of the global production. However, ensuring consistent quality and quantity of dairy products is a matter of significant challenge in our country. Most livestock farms in Assam do not follow basic scientific norms of hygiene and sanitation. The floors are made of mud or similar materials, which contribute severely to biofilm formation. This is evident through the various studies undertaken which revealed subpar bacteriological qualities in milk produced in Assam (Kakati et al. 2021), highlighting a dreadful reality unless acted upon.

Keywords: antimicrobial resistance, biofilms, nanoparticles, mastitis, one health, endometritis, chitosan, chlorhexidine, food safety, food security, Staphylococcus spp., Escherichia coli

DEFINITION OF THE PROBLEM:

India bags the topmost position globally in terms of milk production, with the annual yields reaching an elephantine 239.30 Mt (NDDB, 2023-24), while that of Assam being 1,092 kt (NDDB, 2023-24). Even with such impeccable production status, both the quality and quantity of raw milk are being compromised due to a spectrum of pathogens. According to an evaluation made on the bacteriological quality of milk in Assam, the coliform count was observed to be significantly higher than the legal standards in almost 50% of the 200 samples assessed. As such, the concept is aimed at tackling the following problems:

- Recurring infections of Bovine Staphylococcal Mastitis,due to seepage of dormant Staphylococcus aureus bacteria through the open teat canals post-milking, which are traced to the biofilms attached to the farm floors. This results in a huge decrease in milk yields, culminating in substantial economic damages.

- The occurrence of resistant coliinfections in human beings, due to the consumption of milk collected in utensils having E. coli biofilms attached to their surface. The concept aims to address the issue of poor-quality milk being marketed, leading to compromised consumer health (One Health Importance).

IMPORTANCE OF THE CONCEPT:

In a country as diverse as India, the dairy industry is rooted within the conventional system of herd management. India is not yet successful in optimising the use of its diverse genetic pool of livestock & poultry, as evidenced by the disproportionate rise in milk production and number of livestock when compared to other countries. Moreover, we are severely lacking in the implementation of preventive measures, which in turn results in soaring treatment costs.

The reputation of being the most infamous pathogens that cause havoc through mastitis and endometritis in dairy herds can be tracked down to Staphylococcus aureus, Escherichia coli and Pseudomonas aeruginosa. E. coli also causes gastrointestinal disturbances in humans and animals. These microbes form biofilms resistant to routinely used disinfectants and antimicrobials, which is a matter of concern, as these drugs do not penetrate them, ascribable to the relatively smaller pore size of the biofilms. Thus, routine disinfection with conventional agents does not ensure complete mitigation of pathogens and re-infection occurs.

The prime issue that ignited us to bring up this concept is the ability of dormant bacterial cells of the biofilm to activate whenever they enter a suitable living system. The Extracellular Polymeric Substances (EPS) are digested inside the host by bodily enzymes, resulting in the extravasation of the bacterial components.

On account of these peculiar characteristics of biofilms, it has become the need of the hour to create a solution with nanotechnology as its backbone i.e. to deliver disinfectant agents using potent nanoparticles to kill a broad range of bacteria economically by optimising the manufacturing process with minimum costs involved.

SPECIFIC OBJECTIVE(S): The objectives of this experiment are elucidated as follows:

- Preparation and characterization of Chitosan Nanoparticles (CNPs).

- Evaluation of the efficacy of Chlorhexidine-adsorbed-Chitosan against laboratory biofilms.

METHODOLOGY:

i) Preparation of Chitosan Nanoparticles:

Chitosan is derived naturally from chitin, the biopolymer found in the exoskeletons of crustaceans (e.g. crabs, lobsters, shrimps, insects, fungi, etc). Chitosan can be sustainably produced from several fungi like Mucor spp., Rhizopus spp., etc. These fungi can be grown on SDA Plates in the laboratory and can be processed for chitosan. This chitosan is further processed to obtain the Chitosan Nanoparticles (CNPs).

The following process is employed for the synthesis of chitosan nanoparticles using the Ionic Gelation Method (Jiang et al. 2024):

- Chitosan solution(1 mg/mL, pH 4.7) will be prepared in 1% acetic acid with vigorous stirring for 30 minutes (using a magnetic stirrer).

- Aqueous solutions of TPP (Tripolyphosphate) will be preparedwith the concentrations of 0,4, 0.8, 1, 1.5 & 2 mg/mL and kept at 4°C.

- All the solutions will be filtered through a 0.45 µm filter membrane to remove all insoluble particles.

- Now, 2 mL TPP solution will be added dropwise to 10 mL Chitosan solution under magnetic agitation for 30 minutes.

- After completion of this process, the desired Chitosan Nanoparticles will be obtained.

It is worth noting that great optimisation is required in the Chitosan Nanoparticle production process, thereby reducing costs to meet the demands of small and marginal farmers. One such promising method to achieve economy is the green biosynthesis of Chitosan Nanoparticles (CNPs) by using secondary metabolites found in plant leaf extracts (eg- Eucalyptus globulus leaves) as reducing agents (El-Ahmady El-Naggar et al. 2022).

Fig. Diagrammatic Representation of Chitosan Nanoparticle Synthesis (Ingle et al. 2022)

- ii) In-vitro preparation of Bacterial Biofilms:

- Samples will be collected from animals suspected to be suffering from biofilm-associated infections (mastitis, endometritis, UTIs, etc. being the most commonly encountered problems).

- The collected samples will be inoculated in BHI broth, taking extreme care to eliminate contamination.

- The current data demonstrate that, of the commonly used media, BHI broth is the most conducive growth medium for studying in vitro biofilm and planktonic growth kinetics of aeruginosaand S. aureus, particularly in coculture. (Wijesinghe et al. 2018).

- The samples will be incubated at 35°Cfor 24h (Wijesinghe et al. 2018).

- After the incubation is complete, two types of bacterial growths are observed:

- Pathogenic Planktonic Bacteria: These are the active form of the pathogens and are relatively more virulent. These are observed to be floating throughout the broth, leading to cloudinessof the growth media.

- Dormant Biofilm: These are hardy, dormant pathogens and settle at the bottom of the growth media. The inner surface of the test tube acts as a conditioning film (Percival et al. 2011) and the biofilm remainsadhered to the test tube.

- The incubated broth will be centrifuged at 5000 RPMfor 10 min (Kumaresan, 2014) or any other effective revolution-time combination to separate the intact biofilm pellet. The supernatant will be discarded carefully.

- The weight of the biofilm pellet will be then recorded in order to estimate the cfu/g (colony-forming units per gram).

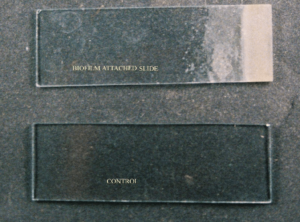

Fig. Picture of a Biofilm Attached Slide VS Control (Kasirajan, 2011)

iii) Introduction of Chlorhexidine-adsorbed-Chitosan on Lab Biofilms:

- A fixed amount of biofilm (pellet) will be carefully placed over three microslides and allowed to settle. They will be designated as follows:

- Test: The biofilm is placed on the microslide, followed by the combined administration of the measured concentration of Chlorhexidine (disinfectant) adsorbed on Chitosan Nanoparticles.

- Biofilm Control: Only the biofilm is placed on the microslide.

- Disinfectant Control: The biofilm is placed on the microslide, followed by the administration of a measured concentration of Chlorhexidine.

- The reagents will be allowed to react with the biofilm for at least 60 min (Orgaz et al. 2011).

iv) Efficacy Testing of the Therapy:

- The content from the test(treated biofilms) and control microslides will be taken for

- They will be inoculated in BHI broth and incubated overnight.

v) Interpretation:

- A reduction in the cfu/g (colony forming units per gram)in the test sample, greater than that of the control samples will be indicative of the fact that the nanoparticle-disinfectant combination (Chlorhexidine-Chitosan) treatment is significantly more effective than any single disinfectant treatment.

- The findings will be further solidified by Confocal Scanning Laser Microscopy (CLSM) (Percival et al. 2011), which is helpful in studying the integrity of test and control biofilms.

- The experiment will be replicated 6 times for the three experimental groups (test,biofilm control, disinfectant control) and the data will be analysed using suitable statistical tools at a 5% level of significance.

Fig. Confocal Laser Scanning Microscopy (CLSM) image of a Biofilm (Tiwari et al. 2019)

EXPECTED OUTCOME: The experiment is expected to yield the following outcomes:

- Mitigation of biofilm-associated infections in the dairy industry, aiding in the maintenance of herd size.

- Elevation of production standards in milk and milk products to the level of international export

- Notable reduction in expensesrelated to herd health management, particularly hygiene and sanitation.

- Effective reduction of biofilm loadsin veterinary establishments (eg- dispensaries, hospitals, farms, etc).

- To combat the phenomenon of recurring diseases and repeated antimicrobial use, leading to AMR (Antimicrobial Resistance).

- Promotion of food safety,food security & ‘one health’.

- Reduction in withdrawal periods in the dairy industry.

- Reduction in the prevalence of biofilm-associated zoonosesbetween animals and humans.

The Chlorhexidine-Chitosan technology will be commercialized and transferred to the dairy farmers using the aid of extension literature, awareness & demonstration programmes, and videography of the performed experiment.

DETAILS OF TEAM MEMBERS:

| S. No. | Participant’s Name | College/University | |

| 1. | Dr. Nayandeep Kalita | College of Veterinary Science, Khanapara | nayandeepkalita@gmail.com |

| 2. | Tridisha Das | College of Veterinary Science, Khanapara | tridishavivek8@gmail.com |

| 3. | Kanjanabh Kumar Das | College of Veterinary Science, Khanapara | kumardaskanjanabh@gmail.com |

N.B. The authors would like to express their immense gratitude to the following individuals for their invaluable guidance towards the completion of this project:

- Shantanu Tamuly (Assistant Professor), Dept. of Veterinary Biochemistry, College of Veterinary Science, Khanapara, Ghy-22.

- Rupam Dutta (Assistant Professor), Dept. of Animal Biotechnology, College of Veterinary Science, Khanapara, Ghy-22.

- Leema Bora (Senior Extension Specialist), Directorate of Extension Education, AAU, Khanapara, Ghy-22.

References:

- Orgaz, B,; Lobete, M.M; Puga, C.H.; Jose, C.S. (2011). Effectiveness of Chitosan against Mature Biofilms Formed by Food Related Bacteria. International Journal of Molecular Sciences. 12(1):817-829. doi:10.3390/ijms12010817. (CrossRef)

- Wijesinghe, G.; Dilhari, A.; Gayani, B.; Kottegoda, N.; Samaranayake, L.; Weerasekera, M. (2018). Influence of Laboratory Culture Media on in vitro Growth, Adhesion, and Biofilm Formation of Pseudomonas aeruginosa and Staphylococcus aureus. Medical Principles and Practices. 28(1):28-35. doi:10.1159/000494757. (CrossRef)

- Kakati, S.; Talukdar, A.; Hazarika, R.A.; Raquib, M.; Laskar, S.K.; Saikia, G.K.; Hussein, Z. (2021). Bacteriological quality of raw milk marketed in and around Guwahati city, Assam, India. Vet World. 14(3):656-660. doi:10.14202/vetworld.2021.656-660. (CrossRef)

- Percival, S.L.; Knottenbelt, D.C.; Cochrane, C.A. (2011). Biofilms and Veterinary Medicine, Volume 6. Springer.(CrossRef)

- Ingle, P.U.; Shende, S.S.; Shingote, P.R.; Mishra, S.S.; Sarda, V.; Wasule, D.L; Rajput, V.D.; Minkina, T.; Rai, M.; Sushkova, S.; Mandzhieva, S.; Gade, A. (2022). Heliyon. https://doi.org/10.1016/j.heliyon.2022.e11893.