Applications of Artificial Intelligence in Poultry Industry

Karthikeyan A.1, Siva M. 1, Reshma A. 1, Sobana A. S. 1, Selvarasu K. 1, Jothilakshmi M. 1, Ramesh V. 1 and Varun A. 2

1 Livestock Farm Complex, Veterinary College and Research Institute, Salem- 636 112.

. 2PGRIAS, Kattupakkam – 603203.

Introduction

In the modern era of Information and Technology, gadgets and electronic devices are now inevitable in our day-to-day life. Technology helps us to do our routine things in a well-organized manner and move forward at ease. In this era, we do have a miniature computer (smartphone) carrying in our pockets, getting not only connected with others but also with the internet giving us a plethora of options and information at our fingertips. Modern technologies viz. Artificial Intelligence (AI), Robots, Sensors devices, Drones, Augmented Reality, Internet of Things (IoT), and mobile apps, etc., could be put into use to exercise smart livestock farming/precision farming. Artificial intelligence (AI) is the ability of a computer to perform tasks that are usually done by humans which requires human intelligence and discernment. In short, AI is the science of mimicking human abilities by a computer. The entire concept of AI would be difficult to elaborate in a single article, hence this article focuses mainly on the application aspects concerning to the poultry industry.

Artificial Intelligence in Poultry Industry

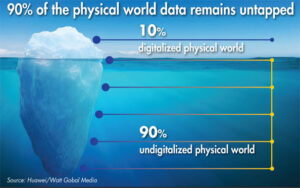

Poultry producers face several key issues involved with such industry-level production like pressure on production cost, animal welfare, lack of sufficient skilled and trained labor, escalating antimicrobial resistance, environmental impact, etc. AI may help in addressing many challenges currently faced in the poultry industry. While still, the majority of the farms are collecting data manually and then getting the data processed in computers. By 2050, it has been projected that a poultry farm would be able to generate 4.1 million data points through various sensors and other related devices connected through the internet of things. The use of AI-based technologies to collect the data automatically and accurately in real-time aids in in-depth analysis which could allow us to immediately act upon optimizing the production performance of the farm. AI can learn from the data in both a supervised and unsupervised manner. Under supervised learning, the AI is trained with already existing data sets that are directed to only certain governed work. For example, predicting expecting body weight for a given broiler line under local conditions. Under unsupervised learning, data collected would be categorized and trends detected without specific programming using resources from the cloud, huge amounts of data could be analyzed to give advance notice of a particular outcome. Big data and data mining would be the greatest resourceful tool in the hands of poultry farmers to harvest the maximum benefit of what they invested. Few ICT companies are focusing to predict the performance based on records and data collected in real-time, this would help the farmer in decision making for optimizing farm production. Usage of a wide range of sensors for measuring bird weight, temperature, feed and water consumption, humidity, ammonia levels, CO2 level, and many more parameters were currently practiced in hi-tech farms. Computer supervised machinery and robotics could reduce sufficiently human interaction with farm birds, reduces the source of infection and also productive work done comparative to the human counterpart. Usage of AI could reduce the error rate to negligible and work 24×7 thus it can improve the efficiency of farming leading to maximizing the farm profit. AI in near future could transform the present face of conventional industrial farming to smart poultry farming or AI-assisted poultry farming.

“A wealth of information is available on poultry farms and more broadly, but most of it is unused.” Huawei and WATT Global Media

In Farm Management

A huge amount of data are generated in the poultry industry providing big data analysis a huge role in farm management practices. Big data stored and processed in cloud spaces can be utilized remotely by AI to govern the machines or robotics to regulate parameters like humidity, temperature, light, etc. For example- Robots with various biosensors connected to the internet of things can be programmed to collect real-time data on parameters like temperature, humidity, ammonia levels inside the farm, further these information can be processed and necessary actions could be initiated if needed. AI will help to constantly monitor farm activities round the clock in real-time which would be an impossible task for humans to perform. Currently, in a large-scale poultry farm, several farm appliances and sensors are available to control the environmental temperature, humidity, and light, but the drawback with them is that they should be either manually operated or human supervision is a must to operate with. With the power of AI, various sensors connected with the internet of things, the farm appliances can be operated from elsewhere giving accurate maintenance of the farmhouse environment at ease.

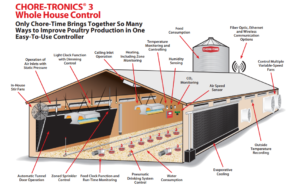

The CHORE-TRONICS® 3 Controller provides complete control over the entire poultry house at every stage of growth. With inputs provided, it automatically maintains precise monitoring and control over the feeding and drinking systems, environment, and a wide variety of data relating to poultry operation. It provides the feed consumption and growth data in real-time, and also helps to spot problems early and fine-tune settings to get the maximum performance from every flock raised. (https://www.choretime.com/uploads/pdf/CT_2537_201707_Chore_Tronics_3_Controller_HR.pdf).

Schematic representation of CHORE-TRONICS® 3 System

The CHORE-TRONICS® 3 System can be connected using a variety of wired and wireless connectivity options and provides all the condition information needed summarized on a single display, no wasting time searching for critical information and alert calls are sent through calls or text notifications to the farm manager to act upon.

NybSys has developed a central controller to monitor and control poultry house environment by having multiple sensors to detect temperature, humidity, and light intensity which are connected with the internet of things and the farm appliance are connected with that of central controller which can be operated through an app from elsewhere just connected with internet (https://youtu.be/Mmp-jZ39fWQ).

Robots are put to use in poultry farms to perform the numerous physical hard work done by human counterparts to take advantage of their presence in farm premises 24×7 throughout the week without any work off. In breeder houses, robots are used to reduce floor egg incidence, resulting in cleaner eggs better hatchability, and reducing human intervention. TIBOT technologies SAS (https://tibot.fr/robotique-avicole-228.php) company has developed a robot (Spoutnic) working round the clock all day reduced the incidences of eggs laid on the floor within two weeks by 26% and to a level of less than 1.5% of floor egg incidence. This provided cleaner eggs leading to increased hatchability. Approximately the return of investment for this robot was somewhere between 9-18 months for given local conditions in France.

Spoutnic robot in action to reduce floor egg incidence

Similarly, the Spoutnic NAV robot (https://tibot.fr/technical-data-spoutnic-nav-333.php#top) was put to use in broiler houses, to stimulate bird activity, contributing to improving both feed conversion (-0.106) and average daily weight gain (+4.4g). It also continuously scratches the litter reducing the humidity, eliminate caking and wet spots, reducing the incidence of aspergillosis, pododermatitis, foot burn, and breast burn contributing to animal welfare. It can also monitor and map ammonia, temperature, and humidity levels throughout the farm to keep in check.

Spoutnic NAV robot in broiler farm raking litter

Likewise, a robot named Octopus Poultry Safe from Octopus Robots Company (https://octopusrobots.com/en/the-company) was designed to sanitize large buildings such as poultry farms and especially their litters and another robot named Octopus Scarifier is designed to aerate the litter in presence of birds and monitor large buildings such as poultry farms. While robot named ChickenBoy-the smart broiler robot from Faromatics solutions (http://poultry.proultry.com/companies/faromatics) was the first-ever roof-suspended robot entrusted to monitor litter and other farm appliances. It has been enabled with the artificial vision to differentiate the droppings, diseased birds, broken pipes, and wet spots in the liter. Provisions are made to send alarm text messages when the critical levels of farm parameters like ammonia, CO2 rise up. Few of the advantages of using ChickenBoy are better digestion management, early disease detection, reduced mortality, fine-tuning of climate control, reduction of scratches and bruises in the chickens.

The most visible signs of employment of artificial intelligence on farms are in the form of robots that not only improve efficiency but also benefit bird welfare. Courtesy-Octopus Robots

ChickenBoy-the smart broiler robot for broiler farming

Wageningen University developed a robot prototype (PoultryBot) to work in layer farms to collect floor eggs while at the same time gather data with sensors to monitor the environment and health of laying hens.

PoultryBot in Layer farm

The utilization of robots in farms provides lesser human interaction with the farm birds giving higher biosecurity and reduced contamination/disease transmission by humans. Robots not only provide with productive workforce but also provides animal welfare, health monitoring, and early disease alerting system.

Disease management

Another area with great potential for AI is in the early detection of poultry diseases, AI if trained with proper data set it has the potential to detect diseases during their incubation period, allowing the producers to quickly act to prevent the spread of disease throughout the flock. When AI complements or augments the human intelligence known as collaborative intelligence, which is much needed in the area of disease diagnosis for efficient and accurate diagnoses with lesser diagnostic interventions. Likewise, artificial vision could be used to capture the postmortem lesion and compare it with that of the database to effective differential diagnosis in collaboration with a veterinarian.

Using Computer/Artificial vision, AI could be trained for detecting early heat stress in birds by using thermal imaging cameras or infra-red cameras. Likewise, diseased birds from the flock can be identified based on their movement, posture, and behavior by image analysis collected from diseased birds and compared with the healthy ones. Computer vision-based chicken monitoring systems were developed to study bird feeding behavior, stress behavior, tracking bird movement, bird distribution within the farm, real-time monitoring, early detection of sick birds, identifying lameness and activity, predicting bird live weight based on 3D computer vision.

Computer vision and image analysis were utilized to detect the most common diseases affecting chicken from the images of chicken droppings. When the AI trained with the data set to detect the common disease from fecal dropping, resulted in an apparent gain of transfer learning with the highest prediction accuracy of 94% and can be suitable for chicken disease detection application.

Sample Images from the Fecal Image Dataset (Coccidiosis, Health, Salmonella).

Voice recognition system clubbed with AI can assist in differentiating bird distress call from that of normal vocalization. Many respiratory diseases in poultry produce unique sounds in affected birds, which possibly could be detected at the earliest with the help of AI trained with the different data sets under supervised learning. This will give an advantage over conventional poultry farming by isolating the infected birds at the earliest from the flock thereby preventing outbreak within the entire flock.

In Hatchery

In hatcher, Viscon groups introduced VINOVO Live Embryo Detection for detection of live embryos inside eggs using a patented heartbeat sensor. The presence of non-viable eggs inside hatcher can be a biological hazard and occupying extra space unnecessarily. Mechanization of this process is possible only through the AI which or otherwise difficult for humans to sense. It ensures a maximum hygiene level and accuracy during handling for the transfer of eggs and inovo vaccination. The product line can process up to 70,000 eggs per hour, depending on the application.

Another revolutionary machine in hatchery by Viscon groups was Vinovo Select Inject™, which allows effective inovo vaccination of the embryo. Through the fully integrated setup created with the Live Embryo Detection Unit and Select Transfer unit, a highly advanced transfer process is achieved. The Vinovo Select Inject™ features patented re-alignment technology, ensuring that each egg is positioned straight whilst being injected, resulting in the highest accuracy of inovo vaccination. (https://inovovaccination.com/)

Vinovo Select Inject™ from Viscon groups

CrystalEgg is a technology that seeks to improve not only the quantity but the quality of chicks that leave hatcheries. CrystalEgg monitors the embryos’ development stage and gives a very clear observation regarding fertile and infertile, alive or dead, and if there is mortality, at what time the mortality occurred. These data could suggest the reason for reduced hatchability and if mortality occurs at the earlier stage could caution the breeder farm. While to make this call it would take two cycles of hatching, but with this technology it takes only a matter of 7 days. Another issue addressed by CrystalEgg system is accurately predicting exactly how many chicks will hatch so that hatcheries can effectively and efficiently plan their sales logistics. With CrystalEgg, incubation conditions can be perfected according to embryos need, leading to better optimization of the incubation process resulting in narrower hatch window.

LivEgg is an in-ovo sexing technology, actually works like a candling machine, instead of taking out only the infertile eggs, it will separate between male and female embryos. Depending on the needs, in layers it retain only female embryos to hatch, while in broiler or breeder it can separate them based on sex to hatch the separately. It can reach about 50,000 eggs per hour. Here eggs are sexed at about the seventh day or earlier than 10 days at least, and at this stage there is not much development of the embryo, so one can just take out the eggs from incubation considering the welfare issues.

In Post-Harvest

The application of AI extends beyond the farm premise, with a wide range of applications in the meat processing plant and egg packing industry. It has the potential to address some key issues in processing plants like painful and repetitive tasks, lack of real-time processing data, and the limiting speed of human interventions. The use of artificial vision offers real-time yield, monitoring of high-value chicken parts, also combined with smart automation to optimize efficiencies. For processing plants, AI allows higher processing speeds and accurate packing of premium value products, translating into more profits and lesser post-harvest contamination. For example, the hyperspectral imaging technique, a form of spectroscopy gives the information on the chemical composition of an object, like a piece of poultry meat, freshness, tenderness, and even identify meat quality issues like woody breast (https://www.ncbi.nlm.nih.gov/pubmed/20460672). Georgia Tech Research Institute found an automated device that can produce butterfly cuts nearly to that of human worker with a processing speed of 10 birds per minute. Motion captured from skilled workers to perform the butterfly cuts was used to create a new algorithm assisting the robotic device outfitted with a knife to outperform the skilled worker. Global Giant Tyson food has already installed a computer vision system at three of its plants intending to track the quantity of chicken moving through their production lines. (https://www.foodmanufacturing.com/capital-investment/news/21115586/tyson-to-count-its-chickens-with-computer-vision).

The egg processing plant also has its share of applications for AI. Modern egg breakers operated at very high speed to separate the egg white from yolk without any trace for various purposes. These AI-assisted computer vision-enabled egg breakers perform 200,000 eggs per hour or roughly 60 eggs per second, making it unmanageable for the human eye to detect an issue, if present. Also, a similar kind of machine could be entrusted to grade the eggs for both detections of external and internal defects of shelled eggs, therefore enhancing the speed of the production line, up to 255,000 eggs per hour or 70 eggs per second.

Apart from the above discussed applications, several other applications of AI in the poultry industry were under prototype study at initial trial phase to develop into a package to be applied in real farm situations. For example, in nutritional studies, machine learning is used to predict the effectiveness of a feed additive on a broiler’s future weight. In poultry breeding, AI could be used to select birds for welfare traits, behavior, and immunity-related traits, and other novel phenomics data produced by the biosensors, which otherwise difficult to measure. Also, the voluminous data captured in real-time could be added to the breeding program empowering a rigorous selection process and with increased accuracy.

Conclusion

In near future, AI will shift the paradigm of the poultry industry into AI assisted farming in various stages of poultry production from farm to fork. It will be a convinced tool to mitigate or to enhance a specific outcome of a farm produce with increased efficiency to tap farm maximum production potential. In the last few years, many companies have already focused on AI-related research and prototype in collaboration with leading universities across the globe. Further use of newer AI-related technologies will augment poultry produce providing affordable animal protein along with animal welfare.