AUTOMATED POULTRY HOUSING

Introduction:

Improvements to poultry housing systems in developing countries have focused on providing an environment that satisfies the birds’ thermal requirements. Newly hatched birds have a poor ability to control body temperature, and require some form of supplementary heating, particularly in the first few days after hatch. Many developing countries are located in tropical areas where minimal heating is required. Indeed, the emphasis in these countries particularly for meat chickens is on keeping the birds cool. In poultry, the chicks mainly depend upon feed, water temperature to survive themselves. In order to provide a suitable condition to the chicks in the poultry, we are going for the automated process which is implemented using ARM and reduces the manpower.

The temperature sensor and moisture sensor are used in order to sense the temperature level and water levels. Depending on the temperature sensed, the number of lights will be on/off. Either Bulbs/LEDs are used as lights.

Water level controller will sense the level of the water in the chamber. A GPIO pin is used to sense the level of feed. DC motors are used to provide the water and feed whenever necessary.

Modern houses are fully automated, with fans linked to sensors to maintain the required environment. Some commercial operators use computerized systems for remote checking and changing of settings in houses. Forced-air furnaces and radiant heating are the main methods of providing heat to young chicks

Automatic Ventilation Management

All poultry houses need ventilation to ensure an adequate supply of oxygen while removing carbon dioxide, other waste gases, and dust. In commercial operations, minimum ventilation is often practiced in colder climates, but not generally in tropical ones (Glatz and Bolla, 2004). In large-scale automated operations, correct air distribution can be achieved using a negative pressure ventilation system. When chicks are very young, or in colder climates, the air from the inlets should be directed towards the roof, to mix with the warm air there and circulate throughout the shed. With older birds and in warmer temperatures, the incoming air is directed down towards the birds and helps to keep them cool. Evaporative cooling pads can be placed in the air inlets to keep birds cool in hot weather. Tunnel ventilation is the most effective ventilation system for large houses in hot weather.

Tunnel ventilation:

These systems are popular in hot climates. Exhaust fans are placed at one end of the house or in the middle of the shed, and the air is drawn through the length of the house, removing heat, moisture, and dust. Evaporative cooling pads are located at the air inlets. The energy released during evaporation reduces the air temperature, and the resulting airflow creates

A cooling effect, which can reduce the shed temperature by 10 °C or more, depending on humidity. Maximum evaporation is achieved when water pumps are set to provide enough pad moisture to ensure optimum water evaporation. If too much water is added to the pads, it is likely to lead to higher relative humidity and temperatures in the shed.

Fogging systems:

Fogging systems are sometimes used to reduce the shed temperature. Fogging works best in dry climates, and usually involves several rows of high-pressure nozzles that release a fine mist throughout the house. The cooling effect is significantly increased by airflow from the use of fans within the shed.

Automatic Temperature Control System

A house or farm must be in suitable climate conditions in which the chicks can survive in a moderate environment. The climate conditions in the poultry influence the health of the chicks if the climate conditions are not up to the standards the chick’s life’s will be in menace. If the temperature conditions are too high/low in the poultry farms may affect the chick’s life. So, we must monitor the temperature conditions regularly and provide suitable temperature conditions for the chicks to survive. For this high efficiency of manpower with regular monitoring and controlling is needed, in order to reduce this. we are implementing an automatic temperature monitoring and climate control system in poultry houses. To implement this automation process temperature sensor is required, which monitors the temperature regularly in the poultry house and updates the temperature values to the control systems. According to the temperature values the control system will process and decide the number of lights to e ON/OFF for maintaining a suitable climate condition.

If the temperature values are too high then the control system automatically will turn ON the dc fan, which reduces the high temperature in the poultry house. If the temperature is too low, then automatically a number of bulbs will be turned ON which creates a suitable temperature for the chicks.

Automatic Feeding System

Feeding is more important. In modern agriculture, reducing dependence on labor and liberating farmers from constant work, increasing management scale and efficiency, all of which can help achieve agriculture sustainability than all others because without feed the chicks cannot survive. To achieve or sustain the timely feeding to the chicks we are going for an automatic feeding system. Development of new technology for poultry feeding using new trend which happens automatically without the manpower here the feed is going to be done automatically to the chicks. For providing the automatic feeding system: we are going with a mechanical work that is, here we are using a chain rope process in which the rope moves in a clockwise and anti-clockwise direction with a bucket holding in it which contains the feed or grains to the chicks. It is given with some prefixed timeslots, when the time starts automatically the rope starts moving in the direction as mentioned above by this, the bucket which is fixed to the rope starts moving and automatically the grains fall into the bowls which are placed near the chicks.

Automated Watering System

Automatic Fountains

The original Little Giant poultry founts have been used by poultry experts for years. These dependable waterers hook up to any standard 1/2-inch NPT pipe to provide a limitless supply of clean water. Safely operates between 10-70 psi. Holds 2 pints of water and waters up to 175 birds. Bowl measures 6 1/2 inches in diameter and 2 1/2 inches deep.

Fount must be hanging off of the ground for it to work. Because it uses gravity and the weight of the water to turn off the valve.

Edstrom Watering System

The Edstrom Drinker valves feature a positive valve shut-off that is virtually leakproof. The key to this design is a combination of the tough, yet springy diaphragm, and the resilient long-life O-ring. When an animal needs a drink, it will seek the drop of water that can be found at the end of the drinking valve. When he drinks, he will move the valve stem causing more water to flow.

Since the valve is actuated by the biting or licking motion, your animal or bird regulates the amount of water used, with little or no spillage. The design of the Edstrom valve allows greater clearance of the valve stem and the sealing system. The result is maximum resistance to mineral deposits. The valve can be operated by an animal with a system pressure as high as 10 P.S.I. or as low as 1/8 P.S.I. Recommended System Pressure can be achieved by using a Storage tank, a float valve-controlled tank, or a pressure reducing valve. The storage tank system will serve up to 75 valves. When planning your system.

Automatic Drinker Cup System

A system with one or two cups or a large system using up to 210 cups. Inexpensive pressure-reducing valve can be used for the small system of one or two cups or large systems. Purchase cups, brackets, tubing, and fittings for your system. These cups have a spring-loaded trigger stem for positive shut-off of water. Water flows only when the bird’s beak is in the cup. No messy wet spots as with nipple drinkers. DESIGNING A SYSTEM – Drink cups require a source of water at a pressure below 5 lbs. PSI is provided by a pressure-reducing valve, or by gravity tanks (less than five feet above drinkers).

The Embedded System

An Embedded system is a device controlled by a set of instructions stored on a chip. These devices are usually controlled by a processor that executes the instructions stored on a memory chip. Compared to general-purpose computer system embedded system has some special attributes like high reliability, low power dissipation, portability, software up-gradation capability, and so on. The embedded system is a combination of hardware, embedded operating systems, and embedded application programs. In the realm of embedded technologies ARM (Advanced RISC Machine) is very popular. According to Wikipedia, around 70% of all 32-bit embedded CPUs are based on ARM architecture. Keil is a software compile, has the flexibility of text editor to create source files; automatically compile, link, and covert using options set with an easy-to-use user interface, and finally simulate or perform debugging on the hardware with access to C variables and memory. KEIL Greatly simplifies the process of creating and testing an embedded application.

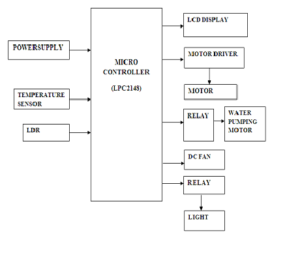

Block Diagram

The following shows the functional block diagram of the project. The various functional blocks required for this project are

- ARM 7(LPC2148) Processor

- Power supply unit

- Sensor

- LCD Display

- Motor

- Light

- Relay

- DC Fan

Conclusion

Automated poultry has several important benefits when compared to manual processing. A shortage of trained labor is forcing Indian poultry farmers to turn to automation to keep their businesses running, in spite of increased input costs. The savings in terms of feed waste, labor cost, improved growth, and efficiency. Many equipment manufacturers are taking advantage of the new trend.LCD display unit for displaying the time, data and to reduce the manpower in the poultry. It is required to monitor the lights, feed, and water to the chicks. Especially in the nights of winter temperature falls below zero or negative temperatures. Due to this, most of the chicks die so we can conclude that automated poultry housing is important for increasing poultry production.

Compiled & Shared by- This paper is a compilation of groupwork provided by the Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request