Automation in Small Ruminants

Rangasai Chandra Goli1*, Kanaka KK2, Pallavi Rathi3, Nidhi Sukhija4, Kiveyi G Chishi5,

1-4 ICAR- National Dairy Research Institute Karnal-132001

Introduction

Automation is the use of mechanical and electronic equipment to reduce the need for human labour. The application of automatic technologies is a growing trend in small ruminants and plays an important role in future prospects. There are many benefits of automation. Machines can be used for repetitive and boring work. In factories, automation can produce more goods in less time with fewer materials. Dangerous tasks can be done with increased safety. In the agriculture industry, automation has resulted in improved crop yields. Automated food delivery systems and animal waste removal systems help small ruminant production by concentrating animals into smaller and smaller areas. Increasing automation enables economies of scale. Many farms have also adopted automated feeding systems and climate control. Computer systems that recognize individual animals enable farmers to care for their animals more efficiently. The most salient characteristic of livestock farm automation systems is the opportunity to tailor operations to the needs of each individual animal. This is only possible if there are subsystems capable of recognizing the animals as they interact with the automated systems. The automatic systems most commonly used in animal production concern the various objectives which include automatic identification, drafting, feeding, milking, detection of estrus, detection of births and many other farm operations.

Automatic identification of animals

Animal identification is a process to identify and track animals. It is done for a variety of reasons including verification of ownership, biosecurity control, record keeping, efficient farm management, registration, insurance and presentation of theft of animals. Identification of animals in small ruminant enterprise is of immense importance to draw attention regarding their status in production as well as performance. Thus, proper identification of animal is very important for understanding the need of record keeping and will provide a base to improve the management of herd. In the past, branding has been the predominant practice for ensuring a secure identification. Since animals were unable to express their own identity, the problem of farmers has always been to provide the symbols or codes that could be uniquely and indelibly recognized and identified after time. In small ruminant, automatic identification systems are generally used in two types of applications, In the first application, the transponder is an integral part of an automated system. Its function is to identify the animal for the control system. Such systems generally employ a fixed antenna, positioned inside a stall (feeding station, milking stand) or along a forced route (entrance to milking parlour, automatic weighing system). The second application involves the recording of events concerning the state of health or reproductive history of the animal. In this case, the automatic identification system simply has the function of acquiring, saving and displaying the animal’s identification code. This application uses portable antenna transponders that, when held near the animal, permit its reliable identification and thereby eliminates the difficulty and risk of error associated with visual recognition of the code. The subsequent data entry and recording operations are performed by the attender of livestock using a keyboard and display, which is normally incorporated into the portable antenna. These systems are particularly of interest in the case of small ruminants and in pig farming.

The electronic identification and monitoring of small ruminants is mostly carried out by:

- Radio Frequency Identification system

- Global Positioning System

- Retinal Imaging & Muzzle Printometry

- Radio Frequency Identification (RFID)

Radio frequency identification (RFID) is one of the advanced and efficient identification technologies in recent years and is widely adopted by various industries. RFID can improve the automatic data collection by taking advantage of electronic transmission technology that provides quick access to herd information and utilized for improving the feeding and managemental practices. The RFID system is composed of transponder, trans-receiver, data accumulator and digital device network. Transponder (Responder or Tag) is a part worn by the animal that is activated by the electromagnetic signal broadcast from the antenna and transmits a code in reply .Trans-receiver (Antenna/Reader/Interrogators/Scanner) is a fixed part which is composed of a transmitter-receiver (antenna) that continually broadcasts electromagnetic signals. Data accumulator is a computer operated software. Digital device network can be wireless, wired or hybrid in nature. The operation of the devices used in automatic identification system is based on the decoding of electromagnetic signals received from a responder (worn by the animal) by the antenna. The tag is read only when it is within the antenna range. After that the antenna receives the tag’s alphanumeric code, it is re-edited and sent to the management software.

- Transponder/Responder/Tag

Transponder is implanted inside the body. Transponder is having silicon chip and an antenna. Silicon chip has 12 digits for identification of animal and 3 digits for country code. There are different types of antenna and tag, which are different in shape and size in accordance to the radio frequency range.

Collar: This is most commonly used. The responder is embedded in a plastic tag that is strapped to the animal’s neck. Electronic collars are similar to that of neck chains, except they have an attached tag with an electronic number that can be read by a scanner. The position of the collar allows for easy and reliable identification of the animals, with the antenna installed either along a forced route (entrance to the milking parlour) or at a fixed location (self-feeder). Electronic collars are easy to use, but they can become a nuisance and can cause choking if they are not adjusted properly to the growth of the animal or if they become hooked on protrusions.

Cuff: The responder is attached to the animal’s leg. In this case, the responders can be equipped with a sensor and internal memory for recording data (number of steps) that is transmitted together with the code at the time of identification. In this case, the devices are called pedometers.

Ear tags: In this case, the responder is affixed to the animal’s ear. The ear tag transponder is one inch in diameter and can be embodied in plastic. It is generally associated with a tag for visual identification, and offers the advantages of low cost, ease of application, and compact size, making it particularly suitable for smaller animals. On the other hand, the likelihood of loss is high (3-5%).

Microchips: Microchips are a form of identification that involves the implanting of an electronic chip, with a miniature radio transponder and antenna, under the skin of an animal near the neck between the shoulder blades, or near the base of the ear, both for protection against knocks and by virtue of the reduced sensitivity of this tissue, which makes application relatively painless for the animal. The risk of loss is very low. However, there have been problems of mechanical breakage of the responder (1-2%). The frequency of breakage is significantly lower for small sized responders (19 or 23 mm). Another drawback of this solution is the greater time needed to recover the responder after slaughtering the animal.

- Trans-receiver/Antenna/Reader/Interrogators/Scanner:

The trans-receiver is a device which sends electronic signals to the tag, which is charged and replies with the stored information. There are two basic trans-receivers:

Fixed RFID trans-receiver: Fixed RFID reader is used at a position in which a farmer wishes to utilize an animal RFID number on a regular basis. These provide a reliable and robust source of identification. These can be used in conjunction with other devices to enable a subsequent action or series of actions to be performed, or decisions to be automatically made. Fixed readers may be utilized to: (1) Identify an animal as soon as it enters the milking parlour, and subsequently recording the time and date (2) Records animal milk production (in association with milk meters) (3) Identify animals required for drafting gate operations etc. (4) Provide the basis for a wide range of optional operations to be conducted within that require individual identification of animals (e.g. automatic feeding etc). Portable RFID reader/Handheld trans-receiver: This may enable identification of animals in the field. Portable readers are capable of reading the RFID tag of an animal in the field and displaying the animal’s RFID number on a small digital screen in-built into the portable reader, and possibly providing an audible reading of the identification number. A portable RFID reader could be attached to a personal digital assistant (PDA) also known as Palmtop computer, which is loaded with herd management software and the data stored on the farms central herd management software application can be copied to this PDA – effectively providing a mobile copy of the herd information. Utilizing this arrangement, the farmer can then scan animal RFID tag with the portable RFID scanner to obtain the identity and information pertaining to that animal on the screen of PDA. The farmer can then use the PDA similarly as he would utilize his host desktop computer to browse the animal’s information and record and update animal information on-site. For example, a farmer could give animal an antibiotic injection – to record this, they simply scan the RFID tag of the treated animal, then use their PDA to record the details of that injection. Such data recording and updates may be immediately reflected in the central herd management software if the portable device has a direct network link to it (e.g. wireless network). Alternatively, if a direct link to the software is not possible, the updated information could be retained in the portable device, and uploaded to the herd management database at a later time when the device can gain a direct link to the network (i.e. transfer via network cable). Either way, the farmer will be receiving the benefits of being able to easily and rapidly retrieve and view data in the field, while also enabling simple, accurate and timely data recording.

iii. Data Accumulator (Herd management Software):

It consists of a computer which works as data accumulator. The computer is loaded with the specific software that allows communication with the readers. Herd management software provides mechanisms for farmers to store individual animal data into a database. Data can be entered into this software application manually via an easy to use, standardized interface, or alternatively, data can be automatically entered through the use of other digital devices linked to this database. Such herd management software also provides RFID devices with the information required to make a decision or conduct an action.

- Digital device network – wireless/wired/hybrid:

A digital device network is required to enable the communication of devices between one another that is RFID readers and the central herd management software. There are essentially three methods of establishing such a network – wired, wireless or hybrid. Now a day’s farmers are utilizing wireless networks. This will enable an array of devices, to be linked directly to real-time data in the herd management database. Various devices include the mainstream computer network devices, such as PDAs (Personal Digital Assistants), laptops, desktop, personal computers and printers, also provide the vital links to dairy farm devices, such as RFID readers, milking controller units, feed management units, drafting gates etc. A hybrid network involves some components of the network utilizing direct wired connections to the herd management software and server application, while other devices are provided with portable abilities. This may be the preferred option where there are devices that are intended to be permanently placed in a position, while other devices require portability. Utilizing the hybrid approach, portable devices can be connected to the network and subsequently the central herd management database at regular intervals (e.g. daily), where they can download the latest information from the central herd management database. The farmer can then remove these devices from the network, and take this device with them out into the field, where they can use this device to view, record updates or modify existing data. However, any changes made will only be reflected in their local portable version of the database at the time of recording. The farmer must then return to base, and attach the device to the central network again to upload the data they recorded while in the field onto the wired central herd management database (synchronizing data between the two). The animal identification device should provide a univocal code for each animal, guarantee the traceability, easy to apply, easy readable and should not be lost or broken easily and also not easy to replace, edit or manipulate.The RFID frequency for animal detection is 134.2 kHz, this is a standard defined by the International Standardization Organization (ISO). RFID technology can detect the animals in a maximum range of 20 – 50 cm . However a range of 100 cm have also been reported. In a huge grazing area detecting the animals could be more difficult only with the RFID. Therefore Global Positioning System (GPS) can be used for tracking the grazing animals.

- Global Positioning System (GPS)

The Global Positioning System (GPS) is a space-based satellite navigation system that provides location and time information in all weather conditions, anywhere on or near the Earth, where there is an unobstructed line of sight to four or more GPS satellites. It is maintained by the United States government and is freely accessible to anyone with a GPS receiver. The GPS technologies based on the latitude, longitude and altitude triangulation of radio signals transmitted by a system of 24 satellites geo-orbiting. GPS receiver calculates the distance to each of the four satellites it is tracking by the amount of time it takes for the signals to travel from the satellites to the receiver. This is a high-tech version of triangulation called trilateration. The first satellite locates the animal somewhere on a sphere. The second satellite narrows the animal’s location to a circle created by the intersection of the two satellite spheres. The third satellite reduces the choice to two possible points. Finally, the forth satellite helps calculate a timing and location correction and selects one of the remaining two points as the animal’s position. Each GPS satellite transmits data that indicates its location and the current time. All GPS satellites synchronize operations so that these repeating signals are transmitted at the same instant. The signals, moving at the speed of light, arrive at a GPS receiver at slightly different times because some satellites are farther away than others. The distance to the GPS satellites can be determined by estimating the amount of time it takes for their signals to reach the receiver. When the receiver estimates the distance to at least four GPS satellites, it can calculate its position in three dimensions. Many authors have described the GPS technology in detail. The use of GPS-collar receivers for tracking animal movement is common in wildlife studies. The most important use for a farmer is of finding the animals location and, therefore, replace the continuous activity of control over grazing farmer. The applications of GPS today cover a wide range of scientific fields, such as topography, geodesy, transportation and logistics, and animal tracking. In the field of animal husbandry, the GPS had found applications in studies relating to ethologists and pasture management. Same researchers were concentrated for detecting and logging the spatial distribution of urine patches of grazing female sheep and cattle . Anderson in 2000 developed a virtual fence through the use of GPS collars reduce labour costs associated with fence construction in rotational grazing.

- Retinal Imaging & Muzzle Printometry

Retinal imaging is a non-invasive method in which a digital camera takes a photo of the retinal vascular pattern. The vascular pattern is shown to be unique between animals, twins, clones and even between eyes. Applications of Retinal Imaging include permanent livestock identification, livestock traceability from farm to fork, tracking disease outbreaks and source verification for food safety. Muzzle printometry is the method taking of the nose-prints of the animals and analysing the imprints for the match. One man can easily take the print, when the animal is in a stanchion, by holding its head under one arm and taking the print with the free hand. Due to the fact that the bovine perspires freely through the pores of the nose, it is necessary to wipe the nose dry before applying the ink. For this purpose flannel cloth is used. The ink is then quickly applied by means of a stamping pad by either rubbing the pad back and forth or pressing directly against the nose. The print is then taken on the paper attached to a small board by pressing firmly against the inked nose, beginning with the lower edge of the paper at the base of the upper lip and rolling toward the face. In order to get clear prints the ink must be applied and the print taken quickly after the nose has been wiped dry as the moisture comes out rapidly from the pores. This causes the ink to run, filling up the grooves of the nose, and produces a smeared print. The design is formed by the subcutaneous facial-nacial glands causing more or less pronounced elevations forming the irregular lines in form of grooves between these elevations.

Automatic drafting of animals

Animals can be drafted by weight, management group, gender, health problems and breed. There are many other ways in which animals can be drafted to enable productive animals, or animals with health problems to be selected automatically. These options include the ability to select ewes by the number of lambs produced or by selecting lambs that were one of a double etc. The drafting crate runs off a compressor and can be powered by mains electricity or by a generator. The reader will read all types of ISO-compliant tags and bolus.

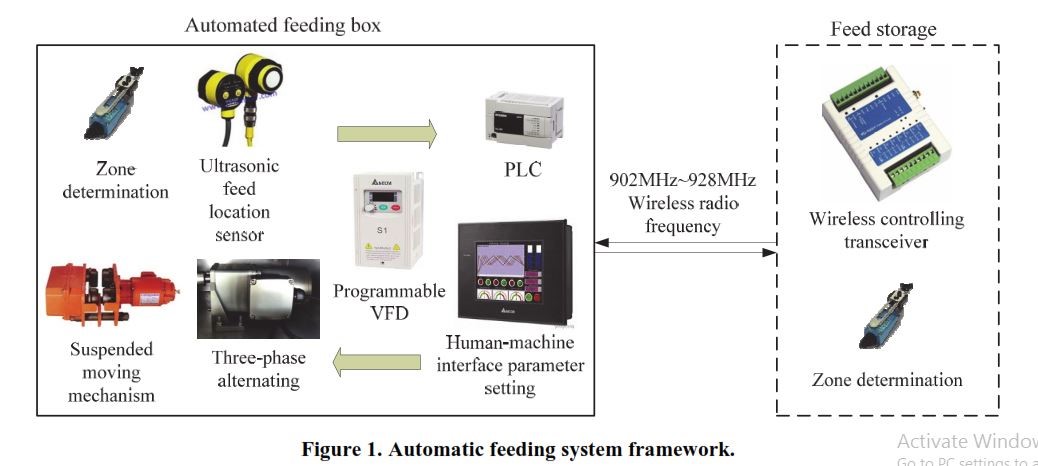

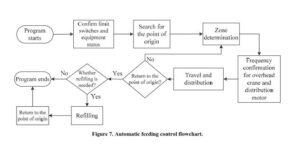

Automatic feeding

An increasing number of farms are relying on automatic feeding to ease their workload, save time and achieve flexibility. Feeding without a fully automatic system accounts for approximately 25% of the total working time requirement. There are various systems which permit the automation of feeding systems. At present rail-guided feed wagons are the best established in practice, but conveyer belts and self-propelled feeders are also used. Grothmann have reported that an automatic feeding system can be installed not only on farms with a big herd or a high milk yield but also on small ones. Many farmers have stated that their animals were significantly less stressed due to automatic feeding and due to feeding several times per day low ranking animals are able to feed better.

Based on the analysis of the currently available Automatic Feeding Systems (AFS) a classification can be based on the possibility of feeding animals individually or per group:

- Individual feeding in free stall-housing:

This option provides the possibility to feed animals with different components, balanced to fit the specific requirements of each animal. The operator fills a temporary storage with the various feedstuffs, from where a trolley automatically collects and transports small loads of the feedstuffs along an overhead rail to small hoppers. From there the system prepares specific rations on demand of the animals by dropping the different ingredients in the individual feeding troughs in small-sized quantities. The small quantities prevent animals to select single feeds.

- Group feeding

The majority of the AFS’s developed at present belong to this group of automatic Total Mixed Ration (TMR) feeding method: the animals are fed with diets balanced for the average requirements of the group and not with individually balanced rations. Combinations are possible with self-feeder concentrate dispensers placed either in the milking parlour/milking robots or elsewhere in the barn.

Automatic milking

Automation in milking can be made including following features.

- Parlour Auto-ID – An electronic radio frequency identification (RFID) system automates the animal identification process. Each animal is fitted with an electronic ear tag with a unique identifying number. It uses antennas to read the unique identifying number and send data to the computer.

- Milk Meter – It is designed for measuring milk yields from sheep and goats. It is an easy to use device that automatically stops the milking when milk flow reduces below a user set level, thus protecting the animals from over milking.

Automated oestrous detection

Numerous physiological and behavioural changes are associated with oestrus and various approaches to utilise these changes to automate oestrus detection have been explored. These include activity monitoring systems (pedometers or accelerometer technologies); mount detectors in which pressure-sensors are placed on the animals tail head and that are stimulated each time the animal is mounted; changes in temperature, vaginal mucus resistance ,changes in hormones such as milk progesterone, lying behaviour and rumination time. Finally, combinations of these measures in the formulation of oestrus detection algorithms have been used to increase detection rates and reduce the number of false positive alerts . In New Zealand, the two main approaches that are commercially available are the activity monitoring systems (pedometer or accelerometer technologies that are either leg or collar mounted) and a camera-based system that automates the inspection of heat patches. All automated monitoring systems include electronic identification so animals can be automatically drafted using alert data. The camera system eliminates the need for manual inspection of heat patches and enables automatic drafting of ‘alerted’ animals. It uses image analysis to classify a heat patch as being non- activated, partially activated, fully activated or missing, at each milking for every animal. The performance of this system is governed firstly by the performance of the heat patch technology and secondly by the accuracy of the image analysis. The first use of leg-mounted pedometers to measure activity associated with oestrus behaviour was in 1977, but their commercial sale is a relatively recent development in New Zealand. Early models were based on simple technology, such as a mercury-switch to count movement events indicative of a step, with the number of steps taken between milking’s recorded. Newer technologies use accelerometers that measure changes in acceleration of the activity device due to animal movements. These measures allow a motion index value or activity deviation to be calculated which can be used to assess changes in the animals activity level. A reference period is used to establish baseline information for each animal from which a meaningful deviation in motion is derived. For example, a system may calculate a seven-day rolling mean for activity (the reference period) against which the current activity value can be compared. The animal is ‘alerted’ as in oestrus when the ratio or deviation exceeds a present threshold. The Artificial Insemination technician or dairy producer can now remotely see data on one or many herds. The webapp can be installed on a number of platforms including PC, mobile phone, iPad, iPod etc . User friendly software has been developed to help one easily monitor the herd 24 hours a day. The intelligent software fully integrates with the Farm Messenger which can be configured to alert the user via a text message a list of animal in heat. The software also integrates with Voice-Assist so that at milking time a voice alert will play on the parlour sound system alerting the operator of a particular animal that is on heat. Auto-Drafting System can be set up to automatically draft active animals to a separate holding pen once milking has been completed.

Summary and Conclusion

Automation is the use of mechanical and electronic equipment to reduce the need for human labour. It has been used for carrying out various farm operations like automatic identification, feeding, milking, oestrus and birth detection, egg collection, exercising, barn cleaning, animal cooling, environmentally controlled housing etc in the livestock farms and grazing lands. Positive points are that automation saves time, requires less labour, improves product quality and FCR, increases production, efficiency, accuracy and safety. Negative points include high installation and repair costs; hence more suitable for commercial & institutional farms.