Bypass protein technology and the impact of feeding bypass protein to dairy animals in tropics: A review

Introduction

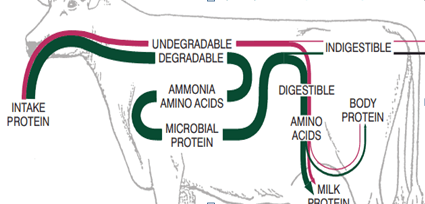

In India, the total annual availability of protein meals is approximately 19-20 MMT, against a requirement of about 30-35 MMT. Out of 20 MMT protein meals produced in the country, approximately 4-5 MMT are exported, which further increases the gap between the requirement and the availability. Protein is usually the first limiting nutrient for cattle fed low-quality forages. In India, farmers feed regionally available protein meals to the dairy animals, along with other ingredients especially in rural villages, remote area and hilly region. A significant part of these protein meals is broken down to ammonia in first stomach of ruminants called rumen having a capacity of 50-60 liters. In the feed fraction of nutrients, which are low or non-degradable in the rumen by the microbes and they are digestible and absorbable at lower tract and become available to animal called as Bypass Nutrient Fraction. The protein can be divided in two parts, for the ruminant animals, in most of the feed, major part is degradable in rumen ‘Rumen Degradable Protein’ (RDP) and a small but variable amount of dietary protein escape rumen degradation ‘ Un-degradable Dietary Protein (UDP) or By pass protein. UDP which enters the lower tract is absorbed mostly as amino acids following enzymatic digestion. Of the RDP fraction, substantial part is utilized as the N source for rumen microbes, for protein synthesis, while the rest is absorbed as ammonia. Only part of absorbed ammonia is recycled back to rumen as urea via saliva, the rest excreted out through urine. The host animal gets amino acids requirement from two sources i.e. microbial protein and UDP, both flowing to lower tract. In growing animals and high yielding animal’s microbial supply is limited then the demand of amino acids at the tissue level, so to support the demand, it is necessary to provide proteins in the form of UDP or escape proteins or protected proteins. When chemically treated protein meals replace untreated one, then due to less degradability of the protein, excessive loss of both nitrogen and energy could be avoided, resulting in an increased energy and nitrogen balance and causing increase in milk yield and different milk constituents. In a typical diet, approximately 40% of the protein eaten must be true protein that escapes degradation, whereas 60% of the protein value can be a mixture of protein and non-protein nitrogen that is degraded and incorporated into the rumen microbes (Tarique et al., 2010). Usually, protein meals are degraded in the rumen to the extent of 65-70 per cent, leading to wastage of nitrogen by its excretion through dung and urine. These protein meals are treated suitably, so as to reduce their degradability in the rumen from 60-70% to 25-30%, in a specially designed airtight plant. Cost of treatment of protein meals is less than a rupee per kg and on feeding one kg treated meal in comparison to untreated; there is increase in milk production by more than a liter. Bypass protein technology is being provided to the dairy cooperatives and private agencies (Gulati et al., 2001).

Appropriate feeding of dairy cattle is of prime importance as feed costs account for more than half of the total costs of milk production. Feed shortage and imbalanced nutrition are major constraints to livestock productivity. Despite these shortages, there is tremendous scope to improve productivity of dairy animals by addressing the issue of imbalanced ratio . A balanced ration must provide adequate quantities of energy, protein, minerals and vitamins from green fodder, dry fodder, concentrates and mineral mixtures. Protein feeds being expensive and scarce, the existing protein resources must be used judiciously. –

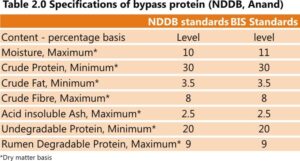

Bypass proteins is an efficient method of improving the protein availability in dairy animal’s diet. These are new generation cattle feed in India and is manufactured by a special chemical treatment, developed by the National Dairy Development Board (NDDB). The ruminant animal has the unique advantage of microbial digestion in the rumen. They supply the major portion of the animal’s protein needs as microbial protein. However, it is inefficient to feed an animal natural protein. The term “bypass protein” shows dietary protein that, either by some means of alteration or because of type of protein is resistant to degradation by the rumen microbes. This undigested dietary protein would “bypass” the rumen and would be potentially available to meet the protein needs of the host animal after digestion in the small intestine.

Protein in ruminant feed

Proteins are biological polymers of amino acids linked together by amide links also called peptide bonds. They contain about 16% nitrogen. The dietary protein for ruminants refers as Crude Protein (CP) which consists of protein component as well as Non-Protein Nitrogen. The CP value is important since protein contributes energy, and provides essential amino acids for rumen microbes as well as the animal itself. Proteins are used for maintenance, growth, reproduction and during milk production in the udder. CP in ruminant diet can be divided into 2 categories based on its degradability during fermentation:

- Degradable intake protein (DIP) –degraded in the rumen to meet the needs of the microbial population. Rumen micro flora breaks the DIP component into amino acids, peptides and ammonia (NH3). This becomes a wasteful process when high quality proteins are broken down to ammonia, excess converted to urea in the liver and excreted through urine.

- Undegradable intake protein (UIP) –proteins that bypasses the rumen to get utilized in small intestine after enzymatic digestion. It is used primarily to meet the extra productive needs of the animalby providing a different balance of essential amino acids for better animal production Characteristics desirable for protected protein supplements is high level of crude protein with optimal essential amino acids profile & approximately 80 per cent of the UIP to be digestible in the small intestine.

Benefits –

National Dairy Development Board (India) has listed the following advantages of feeding bypass protein to ruminants:

- Relatively cheap source of protein for animals

- Availability of essential amino acids is increased

- Improves milk production

- Improves fat and SNF percent

- Improved growth of young animals

- Improvement in reproduction efficiency

- it helps to control Salmonella and reduces mould growth ie. better resistance against diseases.

- Increase the supply of limiting amino acids like lysine and methionine to the small intestine.

- Helps in increasing net daily income

Percentage Bypass estimates of protein sources

| Protein source | % Bypass |

| Blood Meal | 80 |

| Meat Meal | 64 |

| Corn Gluten Meal | 60 |

| Brewer’s Dried Grains | 55 |

| Distiller’s Grains | 54 |

| Dehydrated Alfalfa | 50 |

| Oistiller I s Grains pI us Sol ubles | 49 |

| Soybean Meal | 25 |

Protection of Ruminal Degradable Proteins

Protein and amino acid degradation in the rumen can be decreased by heat treatment (denatures protein with protein –carbohydrates cross links formation that gets protected against microbial attack), chemical treatment with formaldehyde, lignosulfates xylose, tannic acid ,etc , use of amino acid analogues, encapsulation, selective manipulation of balances of rumen metabolic pathways and oesophageal groove closure and use of tannins, and aldehydes. Pelleting, steam rolling or flaking can denature feed protein; therefore protecting protein lysis in the rumen. Starch intrudes with the degradation of protein. It was found that addition of Amylases to cereal grains increased the total ruminal protein degradation.

Results Seen In Production in Dairy Cattles

In tropical conditions, bypass proteins can be fed even to the medium producing animals to increase their productivity. Protein supplement with high bypass value may be considered to increase the milk production of high yielding cows in early lactation when basal diet is poor in nutritive value. Effect of feeding a concentrate mixture containing 37% CP as bypass protein (in experimental group) and concentrate mix containing 50% CP as bypass protein in cows yielding 8-10 litres of milk per day. The animals in experimental group recorded an increase of 1.07 litres of milk per day with a significant increase in fat, SNF and total solids. Whereas the feed costs were reduced, the income of the farmers increased. Higher milk yield in buffaloes fed with formaldehyde treated protein meal. It led to an increase in the yield of 6% Fat Corrected Milk and increase in daily milk production of the order of 1.2 kg per kg of bypass protein in animals fed with bypass protein over those fed with Urea Molasses Block (UMB)).

Protein, an important constituent in ration of cattle and buffalo, when fed to ruminants is degraded by rumen microbes into ammonia, aminoacid and peptides. Subsequently, these degradable products are utilised by the microbes for microbial protein synthesis, but that process may not be always efficient. Moreover, the excess ammonia produced from the degradation of highly degradable cakes, after absorption from rumen wall is transported to liver, converted to urea and excreted out through urine. It is a mere waste of dietary proteins, plus taxing the animal’s energy which is spent on urea synthesis. Although microbial protein is a good quality protein, it may not be sufficient to meet the requirement of high milk yielding animals. So ruminants may also given proteins which are capable of escaping ruminal degradation, called undegraded dietary protein (UDP) or bypass protein, which are degraded in the intestines and absorbed as amino acids. Thus, to meet the nutritional requirements of high yielding animals, feed technologies like rumen protected proteins can be adopted as it has consistently shown not only increased milk yield, but also improved growth and reproduction.

In high yielding cattle, the output in form of milk is more than the input given i.e. feed especially during early lactation. There are multiple reasons for the imbalance, one being the less appetite which results in lesser dry matter intake after parturition while the protein and energy requirements are high during early lactation. This results in mobilization of body reserves which leads to weight loss and finally decrease in milk production. Supply of high protein in diet is not the only solution because breakdown of protein occurs in rumen by microbes. Hence, to meet its requirements, supply of bypass protein can be a good option.

Advantages of bypass protein:

1. Higher availability of amino acids per unit of feed.

2. Better utilization of protein meals having higher rumen protein degradability.

3. Judicious utilization of protein meals, available in limited quantity.

4. Improves growth and milk production.

5. Improves protein percent in milk, hence SNF content of milk.

6. Improves fat percent in milk.

7. Better economic returns, for same input cost.

8. Useful for low and high yielding animals, relevant to Indian conditions of feeding and management.

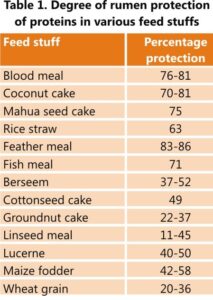

Walli (2002), in his review on bypass protein, reported that inclusion of bypass protein in diet of milch animals has a great potential of increasing milk production in developing countries. Komagiri and Erdman (1992) reported that there was increase in milk production in HF cows that were supplemented with increased levels of rumen undegradable protein. Due to negative energy balance, dairy cows may show longer service period as they suffer from nutritional infertility. A few natural feedstuffs have some degree of rumen protection and important ones are enlisted in Table1.

Bypass protein is an important source for meeting requirements of high yielding animals but better results can be obtained when dietary protein has degradable and bypass protein in the ratio of 40:60. The rumen degradability of proteins can be artificially prevented by treating the protein sources in such a way to decrease its availability for the rumen microbes. The easiest and most common method is heat and formaldehyde treatment. According to Gulati et al. (2001) bypass protein supplements for dairy cow should contain high level of crude protein, optimum essential amino acid profile, 70-80% rumen undegradable protein with near about 80% of digestibility in small intestines.

As discussed earlier, there is some degree of natural protection of feeds.

Further, proteins can be artificially protected from ruminal degradation by following methods:

a. Chemical protection

Proteins are chemically protected by treating with substances like tannins, formaldehyde, glutaraldehyde, glyoxal and hexa-methylenetetramine. But formaldehyde treatment is most commonly used. Formaldehyde treatment has been found effective in improving the bypass protein (Walli et al., 1980) in oilseed meals, hay and silage. 0.5-1.5, 1-3 and 3-5% formaldehyde is used for protein protection in concentrates, hay and silage respectively. Formaldehyde treatment not only increases the rumen undegradable protein in feed stuffs but also increases its acceptability by animals.

Treating protein meals with formaldehyde has the following advantages

1. Desired level of protein protection can be achieved

2. Under and over protection of proteins can be eliminated

3. The bio-availability of the essential amino acids can be maximized

4. It does not increase the proportion of ADIN and NDIN contents

5. Economical

6. The HCHO treatment of groundnut cake arrests further growth of fungi and thus production of mycotoxins in the cake.

b. Heat treatment

Heat treatment to feed stuffs has been found to increase the protein protection (Senger and Mudgal, 1982). It works on the principle that heat treatment causes denaturation of proteins which provides effective protection against microbial attack. Heat treatment at higher temperatures reduces the availability of some amino acids like cystine, arginine so to reduce such losses, steam treatment has been found fruitful. Steam treatment increases both bypassability and digestibility of proteins. However, heat treatment is much costlier and economically not viable.

Conclusions

High yielding dairy animals have high nutritional requirement. During early lactation, if the dietary intake is less than the milk production, they can reach negative energy balance. Feeding of bypass proteins is one of the best methods to meet these requirements. As it directly reach the small intestines escaping the rumen degradation and is available to meet high protein demands of animal. Bypass proteins will also help to maintain normal fertility. Hence, the farmers are advised to adopt mentioned feeding strategies for maximum benefits.

There remains tremendous scope to improve the production levels of the dairy animals even with the existing resources. It calls for a sustainable use of feeds and fodders and an improved efficiency of nutrient availability. Bypass feed technology has been suggested as one such intervention to improve the efficiency of dairy cattle nutrition.