Cold Plasma Technology: Application in Meat Sector

Varun Kumar1* and Vivek Kumar1

1*MVSc scholar, Division of Livestock Products Technology, ICAR- IVRI, Izatnagar, Bareilly (UP)

1PhD scholar, Division of Pathology, ICAR-IVRI, Izatnagar, Bareilly (UP)

Introduction

The rising global consumption of meat and the imperative to ensure its safety, quality, and longevity, given meat’s susceptibility to microbial contamination and spoilage. Cold Plasma (CP) technology emerges as a prominent solution in this context. CP involves ionizing gas under atmospheric or low-pressure conditions, creating bio-active agents such as reactive oxygen species (ROS) and reactive nitrogen species (RNS), ultraviolet (UV) light, and charged particles, which have demonstrated effectiveness against various microorganisms, thereby maintaining the safety and integrity of various meats and meat products.

Cold Plasma offers a non-thermal, environmentally friendly, and efficient method for meat treatment and preservation, ensuring microbial safety while maintaining the food’s nutritional and sensory qualities. It has shown potential in inactivating a broad spectrum of microorganisms and ensuring the microbiological safety of meat products without compromising their quality attributes like color, texture, and flavor. Furthermore, Cold plasma technology stands out due to its operational advantages such as quick treatment, easy device operation, low energy requirement, and ability to operate at room temperature, positioning it as a potentially widely-adopted technology in future meat processing.

Fundamentals of cold plasma technology

Plasma and cold plasma

Plasma, recognized as the fourth state of matter, undergoes phase transformations from solid to liquid to gas and eventually becomes plasma through increased energy levels, exhibiting its distinct characteristics. Cold plasma is comprised of various excited species – atomic, molecular, radical, and ionic – and several reactive species, such as electrons, ions, atoms, free radicals, and excited molecules, plus electromagnetic radiation like visible light and UV photons. Plasma can be categorized based on pressure (low atmospheric and high-pressure plasmas) and thermal properties (thermal and non-thermal). While thermal plasma is achieved by heating gas to exceptionally high temperatures, non-thermal or cold plasma is characterized by non-equilibrium, where uncharged molecules and ions cool significantly more effectively than the energy transfer from electrons, keeping the gas at a low temperature.

Cold plasma, whether generated at atmospheric pressure (atmospheric cold plasma, ACP) or low pressure (low-pressure cold plasma, LCP), produces reactive species and electron densities which inhibit microorganisms similarly. The technology is hailed as non-thermal, since during cold plasma formation, most applied energy is focused on electrons, while gas molecules generally maintain approximately ambient temperature. Cold plasma technology has proven effective for applications in meat processing where high temperatures are undesirable, and it is environmentally friendly due to its minimal water usage, absence of chemical residues, and utilization of ambient air as a working gas.

Cold Plasma Formation

- Generation of Cold Plasma:

Electrical energy is applied to carrier gases (e.g., oxygen, nitrogen) using electrodes. The gas ionizes and forms plasma when power surpasses a certain threshold. At higher power levels, initial sparks can transition into a high-current flame.

- Transition from Gas to Plasma:When gas molecules gain enough energy, they ionize to form plasma. Various energy forms (thermal, electromagnetic, etc.) can facilitate this ionization.

- Chemical Complexity:The chemical reactions in plasma involve multiple species and are highly complex. Wet air plasma chemistry, involving additional elements like water droplets, is particularly intricate.

- Reactive Species Creation:Reactive oxygen species (e.g., O3, O2–) and reactive nitrogen species (e.g., NO, NO2) are generated. These reactive species have the ability to neutralize microbes.

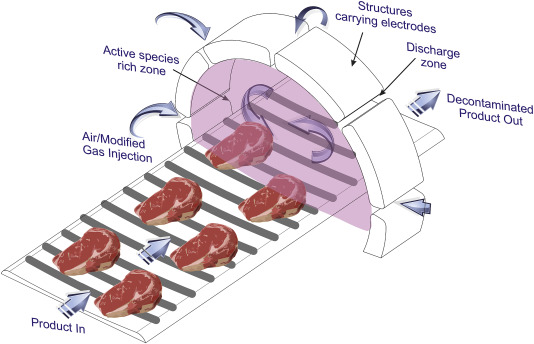

Devices for cold plasma generation

- Dielectric Barrier Discharge (DBD): Here, the plasma is generated between two electrodes separated by a dielectric material. It’s one of the most common methods for food treatment.

- Atmospheric Pressure Plasma Jet (APPJ): A plasma jet generates plasma in a gas stream which can be directly applied to the food surface.

- Corona Discharge: A method where plasma is formed around a sharp electrode tip.

APPLICATIONS OF COLD PLASMA

Cold plasma and Meat safety:

- Pathogen Reduction: Effectively eliminates harmful microorganisms like E. coli, Salmonella, and Listeria from meat surfaces, ensuring safer consumption.

- Extended Shelf Life: By reducing microbial load, cold plasma treatments delay spoilage and extend the freshness of meat products.

- Chemical-Free Decontamination: Offers a non-chemical approach to disinfect meat, reducing the potential for chemical residues and allergens.

- Surface Sterilization:Targets the outer surface of meat cuts, reducing cross-contamination risks in packaged products.

Cold Plasma And Meat Quality:

- Preservation of Nutritional Value: As a non-thermal technology, cold plasma avoids the degradation of heat-sensitive nutrients, preserving the meat’s inherent nutritional quality.

- Improved Meat Texture: Cold plasma can induce subtle changes in muscle fibers, potentially leading to enhanced tenderness in certain meats.

- Color Retention: Cold plasma treatments can stabilize meat color by affecting myoglobin, ensuring the product retains its fresh appearance for a longer period.

- Minimal Impact on Sensory Properties: When applied correctly, cold plasma doesn’t introduce off-flavors or odors, preserving the natural taste and aroma of the meat.

- Enhanced Food Integrity: Cold plasma, as a non-thermal process, ensures meat safety without compromising its quality, texture, or nutritional value.

Surface Decontamination

- Microbial Reduction on Meat Surfaces:Cold plasma targets and reduces harmful pathogens like E. coli, Salmonella, and Campylobacter on meat surfaces, making it safer for consumption.

- Meat Packaging Sterilization:Prior to packaging, cold plasma can be used to decontaminate the inner surfaces of meat packaging materials, further ensuring meat safety during storage and transportation.

- Cutting Tool and Conveyor Sanitization:Cold plasma can be used to sanitize meat processing equipment, preventing cross-contamination and ensuring consistent meat quality.

- Decontamination of Processed Meat Products: Products like sausages, cured meats, and others can benefit from cold plasma treatments, reducing surface contaminants and enhancing product shelf life.

Application in packaging

- Packaging Sterilization: Cold plasma can be employed to sterilize the inner surfaces of meat packaging materials, ensuring an added layer of safety against contamination.

- Enhanced Shelf Life: By reducing microbial contaminants on both meat and its packaging, cold plasma treatments extend the shelf life of packaged meat products.

- Barrier Properties Enhancement: Cold plasma treatments can modify packaging surfaces to improve gas barrier properties, benefiting the preservation of meat freshness.

- Adhesion Promotion:Plasma treatments can modify the surface energy of packaging materials, improving the adhesion of labels or any printed information.

- Eco-friendly Approach: Reduces the need for chemical disinfectants in the packaging process, leading to a more sustainable and environmentally friendly approach.

- Odor and Residue Prevention: Ensures that packaging doesn’t introduce any off-odors to the meat, maintaining the product’s natural aroma.

- Improved Seal Integrity: Cold plasma can enhance the sealability of packaging materials, ensuring airtight packages that preserve meat quality.

Application in meat tenderization

- Protein Modification:Cold plasma induces oxidative changes in muscle proteins, leading to a breakdown of certain protein structures, which can enhance meat tenderness.

- Collagen Breakdown:Cold plasma treatments can lead to a partial breakdown of collagen in the meat, making the meat more tender and easier to chew.

- Non-Thermal Process:Unlike traditional tenderization methods that use heat, cold plasma tenderizes meat without cooking it, preserving its raw state and inherent flavors.

- Shortened Marination Time:Cold plasma can increase the meat’s porosity and surface reactivity, allowing marinades and tenderizing agents to penetrate more efficiently, reducing the required marination time.

Regulatory Considerations

- Approval for Food Contact: Any cold plasma system used for meat processing must be certified as safe for direct or indirect food contact according to regional food safety authorities.

- By-Product Monitoring: There’s a need to monitor and analyze potential by-products formed during plasma treatment to ensure no harmful compounds are generated.

- Treatment Consistency: Regulations may require consistent and standardized treatment parameters (e.g., treatment time, power levels) to ensure product safety and uniformity.

- Worker Safety: Occupational safety standards must be met, considering potential exposure to ozone or UV radiation generated by some cold plasma sources.

- Labeling Requirements: Depending on the region, there may be requirements to label meat products treated with cold plasma, providing transparency to consumers.

- Continuous Monitoring: Systems should be in place for regular monitoring and validation of the cold plasma process to ensure ongoing compliance with food safety standards.

- Training and Education: Personnel handling cold plasma equipment might need specialized training, as mandated by regional or industry-specific regulations.

Challenges and limitations:

- Depth of Penetration: Cold plasma primarily acts on the surface of meat, making it challenging to treat internal contaminants or achieve deep-tissue tenderization.

- Potential Flavor Alteration: While cold plasma may not introduce off-flavors when correctly applied, there’s a potential for flavor changes if parameters aren’t optimized.

- Cost and Scalability: Integrating cold plasma technology into existing production lines can be expensive. Scaling the technology for large-scale meat processing might pose challenges.

- Uniformity of Treatment: Ensuring consistent and uniform plasma treatment across different meat cuts or batches can be challenging, given the irregular surfaces and sizes.

- Consumer Acceptance: There may be hesitancy from consumers in accepting meat treated with a relatively new technology, especially without proper education on its safety and benefits.

Future trends:

- Integration with Smart Technologies: The fusion of cold plasma systems with IoT and AI for real-time monitoring, optimizing treatment parameters, and ensuring consistent meat quality.

- Sustainability and Green Processing: Emphasis on cold plasma as an eco-friendly alternative to traditional meat preservation and treatment methods, supporting sustainable food production.

- Compact and Portable Units: Development of smaller, more portable cold plasma units, allowing for on-site treatments at smaller meat processing facilities or farms.

- Consumer Education and Transparency: Increased efforts to educate consumers about the benefits and safety of cold plasma-treated meats, bolstering consumer trust and acceptance.

- Advanced Research on Flavor and Quality: Continuous research aimed at optimizing cold plasma parameters to ensure no adverse effects on meat flavor, texture, and nutritional value.

Conclusion:

Cold plasma is an emerging and highly reliable technique for decontamination, preservation and sterilization of food materials. It positively improves the bioactive profile, physicochemical property, rheology and shelf-life, as apparent in some foods. Besides, the CAP improves the nutritional quality such as total phenolic compounds, amino acids and sugars in some food products. However, these modifications depend on the mixture of gas utilized for the production of plasma and mode of exposure/ penetration over the food material. Limited literature on the toxicity, lethality, food allergens and biosecurity of the CAP treatment on foods is available.

Therefore, more research on genotoxic/cytotoxic effect of CAP treatment is required to understand the chemical reaction and mechanism of plasma and its secondary products on food. Moreover, it should be noted that the possibility of migration of bioactive compounds in the plasma-treated packaging film necessitates the need to authenticate the existence of hazardous particles and species inside the packaging materials. Hence, safety assessment of packaging application with the selectivity of gases for CAP generation and appropriate elucidation of chemical changes on plasma-treated foods need strict assessment. It is therefore suggested that operational conditions of plasma treatment

References

- Rana, S., Mehta, D., Bansal, V., Shivhare, U. S., & Yadav, S. K. (2020). Atmospheric cold plasma (ACP) treatment improved in-package shelf-life of strawberry fruit. Journal of Food Science and Technology, 57(1), 102-112.

- Cubas, A.L.V., Machado, M.M., Pinto, C.R.S.C., Moecke, E.H.S. and Dutra, A.R.A., 2016. Biodiesel production using fatty acids from food industry waste using corona discharge plasma technology. Waste management, 47, pp.149-154.

- Barden, L., & Decker, E. A. (2016). Lipid Oxidation in Low-moisture Food: A Review. Critical Reviews in Food Science and Nutrition, 56, 2467-2482.

- Jayasena, D.D.; Kim, H.J.; Yong, H.I.; Park, S.; Kim, K.; Choe,W.; Jo, C. Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: Effects on pathogen inactivation and meat-quality attributes. Food Microbiol. 2015, 46, 51–57.

- Lee, H. J., Jung, H., Choe, W., Ham, J. S., Lee, J. H., & Jo, C. (2011). Inactivation of Listeria monocytogenes on agar and processed meat surfaces by atmospheric pressure plasma jets. Food Microbiology, 28, 1468-1471.