CONCEPT OF FLOATING FEEDS,SINKING FEEDS & TRADITIONAL FISH FEEDS MANUFACTURING TECHNOLOGY IN INDIA

Post no-1405 Dt 18/12/2019

Compiled & shared by-DR RAJESH KUMAR SINGH ,JAMSHEDPUR,JHARKHAND, INDIA, 9431309542,rajeshsinghvet@gmail.com

& Ritesh Pandey, JAGO KISAN JAGO,7004551516

The fish culture has undergone a dramatic worldwide growth in the last few years. The aquaculture industry is the fastest growing food production industry in the world and approximately 50% of all fish consumed by humans is from aquaculture. Nutrition plays a vital role in improving animal productivity . Understanding about the nutritional requirements and production of fish feed is essential to the development and sustainability of aquaculture as the industry has matured.

Prepared or artificial diets may be either complete or supplemental. Complete diets supply all the ingredients, protein (18-50%), lipid (10-25%), carbohydrate (15-20%), ash (< 8.5%), phosphorus (< 1.5%), water (< 10%), and trace amounts of vitamins, and minerals necessary for the optimal growth and health of the fish (Craig and Helfrich, 2002). Nutritionally complete feeds should be used when fish are reared in high density indoor systems or confined in cages and cannot forage freely on natural foods or natural foods are absent or where natural foods only make a small contribution to nutrition. When substantial amounts of natural productivity are available, supplemental feeds (incomplete, partial) don’t need to contain all essential nutrients and are intended only to help fortify the natural foods with extra protein, carbohydrate and lipid in the culture systems.

Feeds can be farm-made single component feeds like rice bran or mastered oil cake to commercial feeds. Kitchen wastes may also be considered as one of the types of farm-made feeds produced economically for a small scale culture venture. Farm-made or on-farm feeds consist of one or more artificial and/or natural ingredients, produced for a particular farming activity and not for any commercial purpose. Mixtures of ingredients subjected to some form of processing (simple mixing, grinding and cooking) done on-farm or in small processing plants are generally regarded as farm-made feeds and are often used in small-scale semi-intensive aquaculture practices. Commercial feeds are formulated and manufactured from a homogenous mixer of several ingredients, in various proportions that ensure precise quality targets in terms of size and texture, stability and nutritional composition at a highly competitive price. Commercial complete feeds are used usually in intensive and semi-intensive practices.

Recent trends in aquatic nutrition and food-feed scenario-----------

India is blessed with huge inland water resources in terms of 29,000 Km of rivers, 0.3 million ha of estuaries, 0.19 million ha of back waters and lagoons, 3.15 million ha of reservoirs, 0.02 million ha of flood plain wetlands and 0.72 million ha of upland lakes. Freshwater aquaculture has made notable strides with annual growth rate of over 6 % during last decades. This sector has evolved from the stage of domestic activity in Eastern India, West Bengal and Odisha to that of an Industry in recent years in Andhra Pradesh, Punjab, Haryana, Maharashtra etc. taking up fish culture as a trade. With technological inputs, entrepreneurial initiatives and financial investment, the pond productivity has gone up to 500-600 kg/ha/year to a level of 10000-15000 t/ha/year. The IMC, Catla, Rohu, Mrigal are the major species which are suitably, blended with three exotic carp species such as silver carp, grass carp, and common carp for composite carp farming. The use of oil cake-bran mixture is still in vogue, which is provided in fertilized pond eco system to supplement the nutritional deficiencies. Since the traditional feed mixture is not nutritionally balanced, and intensive or super intensive production is the primary objectives of the industry, there is need to use complete diet which provides the essential nutrients and energy, necessitating and understanding of the basic requirements in order to formulated cheap and nutritional balanced diet. there are differences of feeding fish and land animal, because while feeding fish the nutrients contribution of natural aquatic organism in ponds, the effects of feeding on water quality, and the loss of nutrients if the feed is not consumed immediately are taken into consideration.

• Energy requirements are lower for fish than for warm blooded animals, thus giving fish a higher dietary protein to energy ratio.

• Fish require some lipid which terrestrial do not.

• Fish has got ability to absorb soluble minerals from the water.

• Most of the fish do not synthesize ascorbic acid and must depend upon dietary sources.

• Because the fish are fed in water, the feed that is not consumed within reasonable time leads not only to an economic loss, but greatly reduce water quality. So, feed allowances, feeding method and water stability of feeds are very important consideration for aquaculture, but not livestock feeder.

• Fish convert practical feeds into body tissue more efficiently than do farm animals.

Some feeds are formulated with antibiotics for treatment of Vibriosis, and other bacterial infections are sometimes called medicated feeds.

A. Feed Types:

Feeds can be produced either by steam processing, producing compacted, pressure-pelleted (sinking) feeds; or by extrusion, which produces expanded floating or buoyant feeds.

Floating feeds

In general floating feeds offer numerous advantages over their sinking counterparts. Raw materials are propelled by screws along the barrel of the extruder machine to cook the materials at 120-175ºC for about 30 seconds. The homogenous cooked mixture is forced through a die at high pressure. The material expands because of the pressure difference. Floating feeds are more digestible as a result of cooking process and the heat and pressure deactivate destructive enzymes as well. Increased starch gelatinization helps the feed to be more stable in water by disintegrating less quickly that gives enough time to the fish to take the meal completely. Moreover, the farmer can directly observe the feeding intensity of his fish and adjust feeding rates accordingly determining whether feeding rates are too low or too high is important in maximizing fish growth and feed use efficiency. Another side effect is that farmers can visually monitor the health condition of the reared fish as they come to the surface to take feed.

In contrast, floating feed can be detrimental with respect to consumption by competitors and some fish species.

Sinking feeds

Sinking feeds are solid feed pellets that submerged during application. Bottom feeder shrimp, for example, prefer sinking pellets (density greater than that of water, 1 g/cm3) and will not accept a floating feed (Craig and Helfrich, 2002). The farmer cannot always estimate feeding rates properly in relation to the biomass present in his pond and feeding whether too low or too high than the actual requirement. It cause lower weight gain in a particular age and enlarge the culture period when feeding rate is low. In the other hand, overfeeding causes subsequent loss of feed supplied as well as deteriorating water quality that may results in a number of problems.

B. Feed Ingredients:

Wide ranges of ingredients are used in preparation of aquafeeds. They include aquatic and terrestrial plants (Duckweeds, Azolla, Water Hyacinth, etc.), aquatic animals (Snails, Clams, etc.) and terrestrial-based live feeds (Silkworm Larvae, Maggots, etc.), plant or grain processing products and byproducts (De-Oiled Cakes and Meals, Beans, Grains and Brans) and animal-processing by-products (Meat and Bone Meal, Bone Meal, Blood Meal, Feather Meal, etc.). There are more than 35 low price raw materials found locally in Bangladesh can be used in the preparation of supplementary feed of fish and shrimp (Ali and Hoq, 2010).

Table 1: Ingredients used commonly as sources of protein, carbohydrate and fat.

Nutrient Ingredients used

Protein Fish meal, Dry fish, Soybean meal, Meat and bone meal, Rape seed cake, Mustered oil cake, Soy protein concentrate, Blood meal, Krill meal, Maize gluten.

Carbohydrate Rice polish, Maize, Flours, Wheat meal, Extruded gelatinized starch.

Fat Fish oil, Vegetable oil, Crude oil, Full fat soybean.

A wide variety of additives are used that would have positive effects on growth and feed conversion without causing bacterial resistance to fully utilize valuable raw materials in feed pellets.

C. Feed Production:

Production of feed includes two major steps as feed formulation and processing or preparation.

Formulation

Feed formulation is the process of quantifying the proportion of ingredients to be put together, to form a single uniform mixture or pellet that will provide all the nutritional requirements of the target fish. It is a central operation in feed production, ensuring that feed ingredients are economically used for optimum growth of reared species. It requires a good expertise in fish biology and nutrition along with a deep knowledge about feed ingredients and their roles. Most large-scale fish farmers depend on commercial feed mills for their feeds, to obviate the need to do their own formulations or feed preparation. It is therefore essential that formulations are accurate, to ensure that cultured fish are not adversely affected. Feed formulation is a science and an art at a time, requiring knowledge of feed and fish in view of economic aspects when using formulae.

Feed formulation can be done in two major steps as,

• Ingredient selection and restrictions and

• Identification of nutritional specifications.

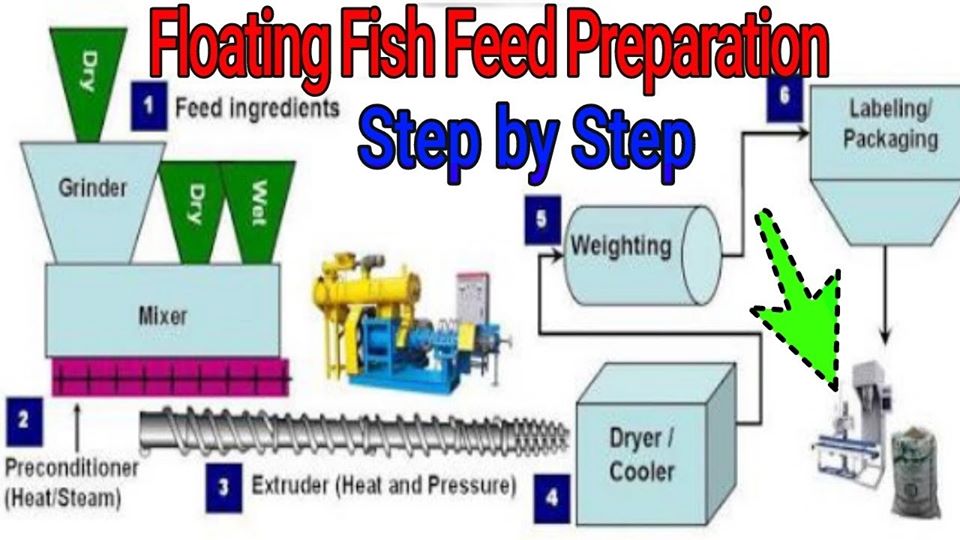

Processing

• Grinding

• Mixing

• Conditioning

• Pelleting

• Drying and

• Packaging

D. Feed Characteristics:

Flavor and taste

Flavor and taste of feed is especially important in the case of bottom feeding animals. Smell can be detected by the specific anatomical receptors in fish, but flavor has to be dissolved in water for the fish to locate it. Some fish have receptors in their mouths, or on the head or lips. Some even have taste receptors on their skin. These receptors carry messages to the brain and tell the fish to swim towards the food. Some kinds of food can strongly stimulate fish to feed by their flavor.

Color and Buoyancy

Some fish that are used to feeding on floating feed may not take to sinking feed that has sunk to the bottom. Similarly, bottom feeders rarely come to the top of the aquarium to eat food. A majority of the fish species in the tropical variety are however not very picky when it comes to the buoyancy of food.

Sound

A fish can “hear” sounds through the vibrations that take place in water. By picking up these vibrations in water, fish become aware of the feeding frenzies that cause many fish to conglomerate when the feeding begins. Also, there are fish that are so used to a routine in their feeding that they start grouping when they hear sounds that normally precede feeding.

Sizes of pellets

Feeds are produced in a variety of sizes on the basis of the die diameter and the cutter blade action. The pellet size ranges from fine powder for small fries or fingerlings to 1/2 inch or larger pellets. The pellet size must be limited to about 20-30% of the diameter of mouth opening of the fish species concerned. In case of feeding too small pellets than the appropriate size, more energy have to be used by the cultured animal during searching and eating more pellets that results in inefficient feeding. On the other hand, pellets that are too large will depress feeding and may cause choking in severe cases.

E. Maintaining feed quality:

A variety of factors govern the quality and wholesomeness of aquafeeds. Feedingstuffs origin, processing, handling and storage, as well as many other factors related to the market, can affect at different levels both quality and safety of feed (Pinotti and Dell’Orto, 2011). Feed quality can be ensured initially by using good quality ingredients. Purchase of raw materials must conform adequate quality, traceability, environmental sustainability and safety standards.

Feed manufactured in the factory is usually of desired quality, but that level of quality may have been fall by the time it reaches a farmer’s pond finally. Commercial fish feed is usually purchased by large farms as bulk feed in truckloads and stored in outside bins (Craig and Helfrich, 2002). Finished feeds undergo deteriorative changes during storage which not only lower their nutritive value below minimum specifications but also affect their palatability and appearance. Feeds should be stored in dry, well ventilated warehouses out of direct sunlight with a minimum temperature change to reduce micro-climatic variations and containment for control of pests. All feed should be used within two months of manufacture and inspected regularly. During long storage there may arise growth of mould, degradation of vitamin potency and fat rancidity. Unnecessary handling damage the feed bags and creates dusts that are not usually consumed by fish and wasted. Pests (i.e. mice, rats, roaches) must be controlled strictly in the storage, to avoid contamination. Proper storage is a simple, but an important part to keep the products at a high quality.

Nutritionists, industry, farmers, and overall the government authorities have to pay attention to animal feedstuff production processes, thereby acknowledging that animal feed safety is an essential prerequisite for human food safety

Fish Feed Production Technology—————-

Feed comprises the biggest cost in intensive fish farming and the objective of feeding fish is to provide the nutritional requirements for good health, optimum growth, optimum yield. India produces enormous quantities of feed materials derived from crops. These include a wide variety of oil cakes, pulses, mill by products, of seeds and grains. Unlike natural food which is normally are present as discreet living forms and therefore biologically stable until consumed, artificial feeds undergo rapid nutrients loss through normal deteriorative processes and leaching by water unless quickly consumed. Moreover, when feed aggregates tend to disintegrate and separate into their ingredients components, thus losing their original nutritional properties. So, a successful artificial feed apart from meeting nutritional requirements should have good water stability and acceptance by the fish. To produce feed with the desired physical characteristic, feed processing and technology has a major role for quality feed preparation.

There are some basic steps of Feed Manufacturing and technology these are:

• Raw Material Collection:

The 1st Operation for feed manufacturing is the collection of raw materials. Initially the raw materials are checked by physical observation and chemical analysis to ascertain the quality. Good quality locally available feed ingredients like maize, soya bean meal, groundnut oil cake, til oil cake, rice bran, rice polish, fish meal, mustard oil cake are procured from the market that arrive in bags or small containers are stored in dry location preferably.

• Grinding:

Grinding or particle size reduction is a major function processing, grinding generally improves feed digestibility, acceptability and increases the bulk density. Different type of grinders are used for grinding the feed ingredients like hammer mills, attrition mills, roller mills, cutters etc.

• Mixing:

This is a process in which each small unit of the whole is the same proportion as the original formula. Only when all ingredients as per the formula are thoroughly mixed, the feed will prove worthy. Various types of mixers are available in the market like vertical and horizontal type.

• Extrusion Cooking:

Extrusion processing has become the primary technique used for fish feed production, mainly because of the high physical and nutritional quality of the feed .Basically, an extruder is a long barrel with one or two rotating screws (single or twin screw extruder) which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exist the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and low density floating pellet is produced. The system is also equipped with a preconditioner as well as an accompanying machine control system. The preconditioner is a high speed mixing unit designed for the purpose of mixing water and steam into the blend of dry ingredients. The Overall goal with preconditioning is to supply the extruder barrel with an evenly moistened and preheated mix. Preconditioning allows more efficient transfer of heat through friction in the extruder barrel, and also reduces the extruder barrel wear and energy. Most materials require milling prior to extrusion, especially large granular ingredients like Maize or Soya. After extrusion, cooling is required to remove excess moisture. A moisture content of 12-14% should be achieved to prevent fungal activity.

• Cooling and drying:

The temperature imparted to pellets after extrusion cooking assists the removal of moisture by the air drying process. Generally, within ten minutes after extrusion, hard pellets are cooled to ambient temperatures and brought to moisture content slightly above that of the entering soft feed. This may be done by spreading pellets in a thin layer on the floor and blowing air over them. Commercially, it is done by passing the hot Pellets through a vertical or horizontal chamber designed to bring air at ambient temperature into intimate contact with the outer surface of the Pellets. The cooling and drying operation are of vertical type or horizontal type. Heated air may be used in the cooling and drying process. Pellets after preparation may also be dried by using dryer fitted with electrical.

• Packing, Storage and distribution:

Most feed are sacked. The sacking operation includes weighing, sacking, taping, coding and sewing. The sacked bags are then sent for distribution. The bulk products are stored in large bins.

Extrusion Technology for Fish Feed Preparation—————

Fish Feed production is done by extrusion technology. It’s the hot, hi-tech food processing technology. One of the Key ingredients in floating feed preparation is starch. Extrusion cooking causes a high level of gelatinization of starches, results in feeds with good water stability. It can produce’ expanded’ floating feeds as well as sinking pellets. The process also improves the digestibility of the product. As we know, the main element of corn is starch, but unprocessed starch will not be absorbed efficiently by the fish. After extruding, the corn is expanded, better utilized and also have good palatability. The starch changed to a feature and can be kept long time at normal temperature.

Parts of Extruder

Parts of Extruder Double-Screw Extruder is mainly composed by the following parts:

A. Feeding System

B. Extruding System

C. Cutting System

D. Heating System

E. Lubrication System

F. Driving System

G. Control System

Manufacturing Procedures for Fish Feed Production

. Manufacturing Procedure:-

The sequence of the series of work or action for making or procedure of goods on a large scale by machinery unit.

the manufacturing procedures of “Fish Feed” production are being divided into the following stages. They are:

1. Stage-1 or Initial Procedures

2. Stage-2 or Main Procedures

3. Stage-3 or Supporting Procedures

4. Stage-4 or Finishing Procedures

STAGE – I or Initial Procedures:

The Stage-I or Initial procedures are those procedures which are required before the mixing of individual ingredients used before the mixing of batches (group of materials/things/ingredients)

The Procedures are:

• Hammering

• Grinding

• Batch-Making Hammering:

The procedure of hitting or beating with a hammer in view of changing the shape and size of the materials. In the “Feed Mill” the Hammering” procedure produces the ingredients of size about 0.5 to 1.5mm. This is carried out by the machine unit known as “Hammer Mill”.

Grinding:

The procedure carried out in order to crush the materials or ingredients into very small particles of powder form. This procedure is being known as “Grinder Unit”.

Batch-Making:

The procedure of arranging/adding of ingredients according to the predetermined proportion/ratio. This procedure can be performed by the

• Individual grinding-to-weighing method Or

• Individual weighing-to-grinding method This procedure is being carried out with the help of an “Electronic Weighing Balance”.

STAGE-II Or Main Procedure:

The stage-II or Main Procedures are the the most important manufacturing procedures in order to produce the fish feed. These are:

1. Mixing

2. Feeding

3. Extruding

4. Cutting

1. Mixing:

This procedure is needed in order to get a homogenous mixture of all individual ingredient taken by batch-making procedures. This procedure is being carried out by the machine name” Mixer”.

2. Feeding: The procedure of supplying of the mixture or materials into the barrel of the Extruder is known as “Feeding”. This procedure is carried out by the machine unit called “Feed Hopper”.

3. Extruding: The procedure of drawing or pushing of heating materials against a die of desired cross-section. This procedure is being carried out by the machine unit called “Extruder”.

4. Cutting: Cutting is the procedure of minimizing or decreasing in shape and size of the materials/product with the help of Knife, blade, saw, chisel etc. In “Feed Mill” the cutting procedure is being carried out with the help of a “Rotating Cutter”.

STAGE-III Or Supporting Procedure:

The stage-III or supporting procedures are the procedures which gives supports in between other procedures during the feed production.

They are:

• Pre-conveying, Conditioning and post Conveying:

The procedure of carrying or movement of the materials from one machine unit to another machine unit. This procedure is being carried out by the machine units named:- �

Screw conveyor

Air blower

Roller conveyor

STAGE – IV or Finishing Procedure:

The stage IV or finishing procedure are the manufacturing procedure needed after the extrusion during the feed production. These procedures are consisting of the following method.

Drying

Grading

Oil spraying

Storing

Farm made feed preparation for IMC—————-

The carp polyculture practice is generally a semi intensive Asian aquaculture system where IMC are grown in earthen ponds, sometimes the exotic carps are also cultivated together with the IMC. In this aquaculture practice natural food are grown in the ponds through application of manure and fertilizers, and supplementary feed is provided to fish. Commercials feeds for carp culture are available in the markets but small fish farmers are unable to use these feeds because of their highest cost. Its generally accepted that feed cost account for the highest single production cost in aquaculture grow-out production of natural fish food organism in the system. Some farmers arbitrarily adopt the use of fish feed as the mixture of soybean meal or ground nut oil cake with rice or wheat bran. The price of all these above ingredients are increasing day be day which farmers are unable to afford. Fish needs more proteins in their diet than the land animals. Plant protein are used as sole dietary protein for carps. Incorporation of soyabean or ground nut oil cake as ingredients becoming too competitive and costly especially for farm made feed formulation.

Some fish feed ingredients and their proximate chemical composition.

Ingredients —Crude Protein % —–Crude Lipids %

Ground Nut Oil Cake 40-45 6-8

Mustard Oil Cake 35-37 5-6

Sunflower Oil Cake 30-32 6-7

Linseed oil Cake 30-32 5-7

Till Oil Cake 35-36 4-5

Soybean Cake 45-47 1-3

Copra Cake 20-25 6-10

Cotton Seed Cake 32-35 6-8

Deoiled rice brand 15-18 1-2

Wheat Brand 11-14 2-3

Rice Brand 10-12 10-12

Rice Polish 12-18 12-14

Form of the farm feed: ————–

Most of the fish farmers use mash feed in semi-intensive carp culture. Pellet feeds have certain advantage over mash feed. It is not that difficult to prepare feed pellets at farm site using locally available ingredients. The common procedure and working steps for farm feed pellet preparation are as follow:

* Based on the nutrients availability of the ingredients, the proportions of the ingredients to be mixed for feed preparation.

*The ingredients are grown to powder form with an electricity operated pulverizer and mixed thoroughly.

*Wheat flour [ Maida] is added 2% level of feed mix.

*Feed mixed is steam cooked to reduce intrinsic anti-nutritional factors and also to increase the binding capacity of particles in feed pellets.

*Dough is prepared from the feed mix by adding required quantity of water

*The dough is passed through an electrically operated portable pelletizer to produced feed pellets. *Different dice are used to prepare pellets of different size.

*The prepared feed pellets are sundried properly before utilization or storage.

*The feed pellets are crumbled to feed the fry and juveniles.

Feed Size:———-

The most important factor is particle size of the food irrespective of its nature such as natural or supplementary. Spawn and early fry prefer food particle smaller than that their mouth size and smaller than that of physically capable of ingesting. Keeping this in view the pond fertilization programme and timing of base manuring should be decided to get small plankton or suitable supplementary feed is to be supplied soon after the stocking of spawn. Some information on feed particle and pellet size is given below:

• Fry 0.5 mm dia crumbled pellet

• Fingerling [3-4g] up to 2.0 mm dia crumbles

• Growout/Brood up to 3.0 mm dia pellet.

Quality control of Fish Feed————–

Quality control is the in-plan processes that insure quality parameter implementation to achieve consistent products. It ensure the degree of consistency of the final product and its efficiency of utilization. It describe and directs the use of formal tests to meet the predefined standard. Any deviation from the standard affected the end products consistency and also its efficiency if correctives measures have not taken up carefully. Its provides knowledge concerning the exact composition of raw materials and the level of toxic substances normally present so that mixed feeds of the required nutritive value can be safely processed from them. The objective of quality control of feed stuffs is to ensure that the consumer should obtain feeds that are claimed for, true to their nature & produce desired results. Quality control measures are required for quality assurance and in feed production system implemented at three levels.

*� Raw material quality control �

*Quality control during processing or manufacturing. �

*Quality control during storage of ingredients or final products.

Compensatory Growth in Fish:————-

In commercial fish culture, feed is the major input constituting 50-60% of the operating cost. Without affecting the economics of fish culture, development of a standard feed and feeding strategy is essential to improve the growth and feed efficiency of fish, save the feed and labour cost and to avoid organic load/pollution, leading to sustainable and eco-friendly aquaculture practices. The compensatory growth is defined as the ability of a dietary restricted animal to achieve its normal body weight and from by a growth spurt re-alimentation. After a period of feed deprivation or restriction, animals have potential to compensate or catch up resulting increased growth rate after full feeding is resumed. In order words, the compensatory growth is a process in which animals that have been “stunted” by an impoverished environment grow rapidly and catch up animals of similar age once the environment is optimal. Period of feed deprivation can be used to increase feed conversion efficiency resulting more growth in fish.