Effect of Flooring and Flooring Surfaces on Lameness Disorders in Dairy Cattle

Dr.Himanshu Pratap Singh, Dairy Consultant, Indore.

Lameness is a common problem in all classes of cattle particularly seen mostly among the stall fed dairy cattle kept on the concrete flooring in the urbal and semi urban area of India which can greatly affect the welfare and productivity of the animals. Lameness is not a single disease but a symptom associated with a range of different conditions. Herd prevalence rates can vary hugely between farms because many factors can predispose clinical lameness. I have seen a large no of high yielding productive cattle used to cull from the farm due to the lameness problem which mostly occur due to hard concrete flooring.

A number of predisposing or risk factors influence, either alone or in conjunction with one another, the severity and the prevalence of lameness. In stall fed based systems in India , one of the major factors that has been identified as being associated with an increased incidence of lameness is poor maintenance or condition of cow shed floor made up with concrete floor.

Why is it important?

Lameness decreases mobility and dry matter intake, causes a drop in production and impairs reproduction.

Preventing lameness will:

• optimize production

• improve conception rates

• reduce cow treatment costs

• lower cow and farmer stress

• improve the health of cows

A simple system of scoring cows is to grade them from 0 through to 3, where 0 is normal and good mobility and 3 is very lame. Once each cow has been graded, a plan of attack for treating lame cows can be implemented. Grade 3 cows that are very lame, are often treated time and again, by farmer and vet. These cows are broken and will often never become sound. They should still be treated as effectively as possible to maximise their comfort and improve their welfare, but a realistic cap should be put on their treatment costs. If all that is required is a quick corrective trim every 1-2 months then this can be very economical. It has been demonstrated that this can dramatically increase the cow’s longevity, although she may never be eligible for live off-farm transport. A far more effective use of resources is to tackle the grade 2 or grade 1 cows, to get them back down to grade 1 or 0, as they can often be cured. Score 2 cows are not always immediately obvious so regular mobility scoring is often the most practical way of identifying them and treating them early.

A number of predisposing or risk factors are thought to influence, either alone or in conjunction with one another, the severity and the prevalence of lameness.

The incidence of lameness, and the lesions associated with the lameness, varies widely between different management systems – for example, between pasture fed cattle and cattle maintained indoors for large parts of the year.

Foot lameness may be caused by a single factor such as direct trauma to the sole of the foot, but more commonly a number of factors may contribute to an increased incidence of lameness in a herd.

Poor track maintenance and design

• Impatience moving the cows along the track or in the yard

• Long periods of time spent on concrete, or cows twisting and turning on concrete yards

• Excessive moisture

• Nutritional effects, including the effect of subclinical rumen acidosis (SARA) and the effect of trace elements and minerals on hoof production.

• Specific infectious agents

• Genetic factors

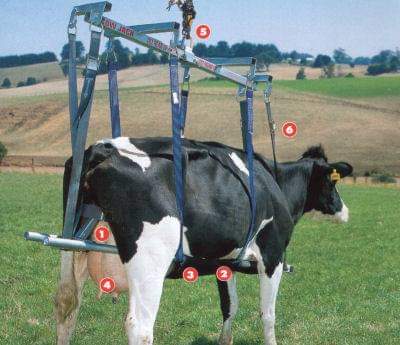

Lameness of cattle, especially in dairy herds remains a significant challenge to animal welfare. It has serious effects on dairy herd production in terms of affecting fertility and milk production parameters, with lame cows taking longer to get back in calf and requiring a greater number of services confinement conditions require cows to stand and walk on hard flooring surfaces. The unyielding nature of solid surfaces (such as concrete) promotes claw horn overgrowth, thereby creating unbalanced weight-bearing within and between the claws of the foot. This predisposes to claw disorders, most notably ulcers and white line disease. In conditions where concrete floors are also abrasive, there is excessive wear on the claw’s weight-bearing surface. Excessive wear of the sole results in the development of thin soles and, frequently, lesions in the toe. Confinement conditions also limit cows to a smaller area, thereby increasing exposure of the cow’s foot to manure slurry and moisture. This increases potential for the development of infectious skin disorders of the foot (particularly digital and interdigital dermatitis) and heel horn erosion.

Cows, Claws, Concrete, and Confinement———-

Cows are land animals. They prefer soft surfaces for walking and lying down. Hard flooring surfaces are less comfortable for cows and contribute to claw horn overgrowth and weight-bearing disturbances that predispose to lameness. The unyielding nature of hard flooring surfaces in combination with concomitant diseases, such as laminitis, can lead to the development of such claw disorders such sole ulcer and white line disease.

Claw lesions are often indiscriminately referred to as sole abscesses. However, a sole abscess is more accurately described as a secondary condition frequently occurring secondary to a sole ulcer, white line disease, or traumatic puncture of the weight-bearing surface of the sole or heel. The pathogenesis and underlying causes of each of these conditions is different. For that reason, it is useful to define them accordingly when recording claw lesions.

A sole ulcer is a circumscribed lesion of the sole that frequently exposes the underlying corium. These may occur on the weight-bearing surface of the toe, heel-sole junction, or on the heel and may result in profound lameness. Sinking and rotation of the third phalanx , subsequent to laminitis or relaxation of the suspensory apparatus , in combination with overgrowth and excess or disproportionate weight-bearing are believed to be important causes of these lesions. The development of ulcers is exacerbated by exposure to hard flooring surfaces and housing conditions that predispose to poor cow comfort.

The white line is the softest horn within the claw and weight-bearing surface. It joins the hard horn of the wall with the softer horn of the sole, thereby making a flexible junction for the union of these structures. Unlike horn of the wall, heel, and sole, horn of the white line is structurally weaker because it does not contain tubular horn. Its strength and resistance to physical forces is determined largely by the degree of keratinization occurring within the cells that make up the white line horn. Formation and accumulation of keratin within developing horn cells is dependent upon health of the corium. Laminitis, for example, is a disease that affects the corium and greatly reduces the integrity of claw horn because it interferes with keratin formation and development of horn cells. Therefore, separation and disease of the white line is a common consequence of laminitis. In addition to laminitis, the white line is vulnerable to mechanical damage and concussive forces because of its location on the weight-bearing surface.

Punctures of the sole leading to abscess formation are not uncommon. Such lesions are usually secondary to sharp stones or other extraneous debris that may be found in cow lanes and alleyways. Nails and screws often accompany recent construction and small bits of wire may be found in barns with worn rubber belting used on flooring surfaces. Keeping track of the various types of foreign bodies found in claws or feet is, therefore, important to sorting out the underlying causes of lameness due to traumatic lesions of the sole.

Concrete, depending upon formulation and how it’s finished, is capable of creating an extremely abrasive surface for a dairy cow’s claws. New concrete is more abrasive than old, and wet concrete is up to 83 percent more abrasive than dry concrete . Where floors are abrasive, claw horn may easily wear more than it grows during the first two months on concrete. Animals housed on wet concrete suffer doubly: first, because of the increased abrasiveness associated with wet concrete and, second, because moisture softens the claw horn, thereby permitting an increased rate of wear. Another important cause of accelerated claw wear occurs from poor handling procedures where crowding or rushing cattle results in increased wear from twisting and turning on rough abrasive flooring surfaces. Proper design of facilities incorporating ideas for easing cow movement and, thus, reducing rotational forces on claws are important housing considerations.

In recent years, there has been significant interest in ways to reduce the negatives of concrete by using cow mat or by incorporating rubber belting along feed mangers and in alleys or walkways to and from the milking parlor. Observation of cow behavior indicates that cows prefer the softer surface offered by rubber belting. In fact, where stall design is poor, cows may find the rubber flooring more attractive for resting than the adjoining stall. When this happens cows may block access to the feed manger. Rubber belts can also be slippery walking surfaces when wet. Grooving belts as described above for concrete surfaces helps reduce slipping injuries. The use of belting that contains reinforcement wires should be avoided. As will be discussed later, these wires frequently become a source of trauma-causing punctures of the sole.

The primary problems with rubber belting are related to manure handling issues and securing them to the underlying floor. For example, in flush barns where rubber may not be properly or completely secured, manure and other debris may become entrapped beneath the rubber. In barns that scrape manure, depending upon how the rubber is secured to the floor, scraping or pivoting of the scraper itself may result in displacement of the rubber. Rubber flooring must be secured in such a way as to make it resistant to dislocation by either the twisting or turning action of the wheels of the scraper. Despite these drawbacks, rubber belting is a floor surface modification that improves cow and foot comfort, but additional research is needed to confirm this observation and provide direction on how to optimize its use in dairy facilities. Rubber is not a substitute for a poorly designed stall. In herds where belting does not work well it may be due to other cow comfort issues (e.g., poor stall design, heat stress) that have not been properly addressed.

Confinement exposes the feet of animals to greater amounts of manure slurry and moisture. Since claw horn absorbs moisture readily, feet of cows in free-stall housing systems are softer. In housing systems where floors are abrasive, wetter, and, thus, softer, claws wear more rapidly, predisposing to thin sole problems. But, in addition to effects on horn hardness, at least one study indicates that the exposure of claws to manure slurry has very detrimental effects on the intercellular matrix of claw horn .In other words, the health and integrity of claw horn is reduced for cows with near constant exposure to manure slurry. Possibly the best example is heel horn erosion, a disorder observed almost exclusively in confinement housed animals. It is believed that manure slurry not only increases the susceptibility of heel horn to erosion but also provides the ideal environment required to support the growth of organisms that actually break down and destroy the heel horn.

Control and Prevention of Lameness

One of the major reasons for increased lameness in herds is reduced lying time. Straw yards, provided they are clean, well bedded and spacious, are excellent in that they provide comfort and the animals are able to move freely. Cows lie down longer in straw yards, and they are better for lying in than many cubicle. The cows also ruminate more and have improved digestion. Stress due to social status is also reduced in straw yards. Even if animals are not housed in straw yards throughout lactation, it is often useful to place cows into a yard for the first part of lactation. Straw yards are also excellent for wintering suckler beef cows and their followers.

If cubicles are used in the moder dairy shed in India then they should be designed correctly, so they do not cause injury and do provide cow comfort. Overcrowding should be avoided by allowing each cow access to at least one cubicle; extra cubicles can be helpful and at least a 5% surplus of cubicles for the number of cows will reduce the risk of less dominant cows being bullied out of cubicles .

Cubicle bases should be kept clean and dry by scraping out slurry at least twice a day and renewing the bedding material as necessary to reduce prolonged contact between their feet and slurry.

Sand is the most comfortable bedding material. If this cannot be used mats or mattresses should be fitted, as they will improve cubicle comfort.

Cubicle surface can affect lameness.———

To reduce problems with lameness in heifers which are to come indoors for calving, they should be housed for 6 to 8 weeks prior to calving to acclimatize them to concrete surfaces. If cubicles are used in the main dairy herd, heifers should be trained to lie in them from a young age, preferably by housing with small groups of older cows, for example by housing with dry cows, or including cubicles in some part of the rearing period. If at all possible, heifers should be kept as a separate group during the first lactation, to eliminate bullying by older animals. Ideally, they should be kept in a straw yard during the first lactation, or at least for the first three months of lactation and until after they are pregnant.

Cow tracks are also critical, particularly in situations when cows are required to walk long distances to and from milking. Ensure cows are not hurried when walking to and from pastures. They should not walk for more than 0.5 km on concrete or tar-macadam surfaces. Wherever possible, special cow tracks should be constructed. Passageways inside buildings must be wide enough (2.7 – 3 meters) and kept clean. Scrape out passages regularly and ensure buildings are well ventilated to reduce water pooling. Repair any areas where slurry pooling occurs. Cows should also have enough space at feed barriers (at least 60cms per cow) to avoid excess standing.

Specialist advice on floor design should be sought to avoid cows slipping and injuring themselves, but here are some useful suggestions:

Floor surfaces must not be too slippery nor too rough.

Concrete surfaces must be cleaned regularly, as both silage effluent and slurry cause erosion

New concrete surfaces must be well washed before use to remove all the excess surface alkali.

Slatted floors can cause lameness in cattle due to injuries if the slats are fitted incorrectly or poorly maintained.

The best way to avoid the lameness problem in the dairy herd is to provide either soil or sand to the dairy shed for laying the dairy cows.The concrete floor should only be used at the time of milking n feeding and rest of the time should be used on either soil or sand.Cow mats are available in the market at very cheap rate so it can be also used above the concrete flooring for providing cushion or bedding.It also reduces lameness in the farm animal to a great extent.

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.