EFFLUENT TREATMENT FROM BY-PRODUCT PLANT

Author: S.P. Mamatha., Arun Kharate, Sarita

Dr. Mamatha S.P., Assistant Professor Dept of VPH (Veterinaary College Bidar)

Dr. Arun Kharaate., Assosicate Professor (I/C) Dept of VPH (Veterinaary College Bidar)

Dr. Sarita .,Assistant Professor Dept of VPY (Veterinaary College Bidar)

Email: msp89353@gmail.com (6361126643)

: kharatearunvet@gmail

:saritapasare@gmail.com

ABSTRACT :

Rendering plants produce large amounts of effluent. The wastewater contains chemicals with a low long-term environmental risk, but they need to be treated before being released into lakes, rivers, or streams. Federal, state, and municipal laws and regulations govern the release of wastewater. Protection of aquatic life, protection of human and animal health, preservation of receiving stream aesthetics, and preservation of water supply quality are the four main environmental concerns relating to wastewater produced and discharged by rendering factories. The most significant attention and expense in wastewater treatment is required for aquatic life protection.

Key words: Rendering plants, Effluent, preservatives

INTRODUCTION

The types and conditions of the raw materials, the kinds of rendering processes used, and standard housekeeping procedures all affect the rates and characteristics of the wastewater generated by rendering facilities. Relatively low volume but extremely high concentration wastewater sources are frequently the cause of wastewater issues. With a production capacity of three to seven million pounds of raw material per week, a typical dead stock rendering factory produces 100,000 gallons of wastewater per day, with 5,000 pounds of CBOD and 900 pounds of TKN per million pounds of raw material.

Wastewater is produced by a typical rendering plant from the following sources:

- Liquid raw materials

- Hide operations; processing of restaurant grease; processing of blood; plant cleaning and sanitation; processing of cooking condensate; devices for reducing air pollution.

- Storm water; non-contact cooling water

COMPONENTS OF RENDERING EFFLUENT

Stickwater is typically 4%–7% fat and other particles from low-temperature wet rendering. The amount of protein and fat lost is substantial. Rendering plants must compare the costs and benefits of “end-of-pipe treatment” versus recovery or prevention at the source. Recovery is typically easier with concentrated effluent streams as opposed to a dilute combination.

EFFLUENT SOURCE – TYPICAL RANGE OF POLLUTANTS (mg/L)

| TDS | P | N | COD | Oil and Grease | |

| Raw material bin drainage | 6000 – 14500 | 300-700 | 3000-5500 | 40000-65000 | Up to 10000 |

| Tallow processing | 20000-35000 | 70-120 | 250-400 | 50000-70000 | Up to 50000 |

| Blood processing | 2000-20000 | 75-150 | 1200-8500 | 15000-100000 | Up to 500 |

| Cooker condensate – HT rendering | < 200 | < 25 | 200-400 | 700-3600 | < 100 |

IMPACT OF RAW MATERIALS

Contaminants entering the waste stream are a problem that begins with the source material. Fresh raw materials generate tallow of the greatest quality and value, minimise the ammonia content of the condensate from high temperature rendering systems, and reduce odour emissions throughout the entire rendering process. Before size reduction, materials should be sent to the raw material bin. Size reduction has to only take place right before the material is fed into the cooker or preheater. Avoid using Hasher Washer systems in conjunction with pneumatic conveyance. The pace of material deterioration and the amount of effluent lost from raw materials are both maximised by this way of preparation. Raw materials can be preserved using either of two methods: acid stabilisation or refrigeration.

METHODS OF RENDERING PLANT EFFLUENT TREATMENT

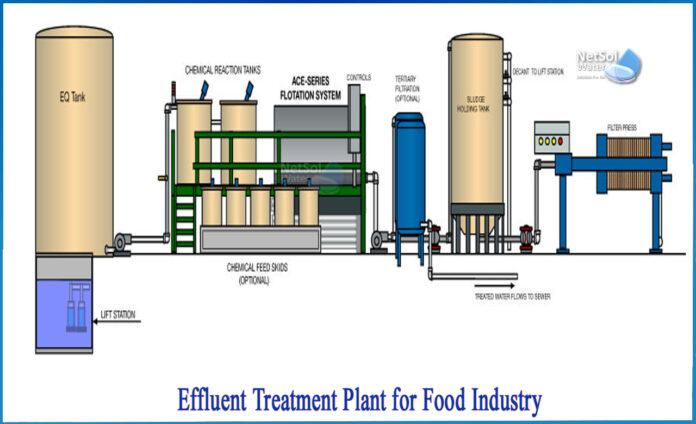

The physical separation of fat and solids by screening or dissolved air flotation (DAF) should be the first step in the treatment of effluent in order to enhance the recovery of fat and protein that may be recycled for further processing.

Pond systems, chemical dosing, and activated sludge systems are examples of secondary treatment. Large amounts of sludge can be produced using activated sludge systems and chemical dosing. When chemical dosing is used, the recovered sludge might not be appropriate for further processing in the rendering plant because of chemical residues. In activated sludge systems, the process may be planned to nitrify or denitrify the effluent or create sludge with a high protein content. Water percentage in solids and sludge recovered from waste water treatment can range from 90% to 98%. Excess water can be removed using techniques like centrifuging or vacuum filtration, which lowers the cost of drying or reprocessing. Protein and fat can often be valuable commodities that can be recovered, processed, and turned into finished goods as an alternative to off-site disposal or payment to a sewage treatment authority. Rarely do DAF systems deliver sludge with a solids content more than 7.5%. Therefore, processors should think about either another means for concentration, such as a centrifuge or vacuum filter, or direct collection and return to the source rather than letting concentrated effluent such as raw material seepage or LT rendering stickwater to enter the effluent system.

PRIMARY PRETREATMENT

Traditional wastewater pretreatment involves removing oil and grease as well as suspended particulates before wastewater is discharged to municipal sanitary sewers. The CBOD percentage that is linked to the suspended solids is also removed when the suspended solids are removed.

SECONDARY TREATMENT:

The term “secondary treatment” describes the biological processes used to remove organic pollutants. The same fundamental natural biodegradation of organic material occurs in streams and lakes throughout secondary treatment operations. In order to remove the organic matter from the wastewater more quickly than in the natural aquatic environment, biodegradation takes place in tanks with extremely high concentrations of microorganisms.

- Aerobic lagoons

- Batch treatment process or Sequencing Batch reactors

Disinfection:

Pathogenic organisms must be eliminated during disinfection. The disinfection of wastewater from rendering plants is frequently accomplished using a potent oxidizer like chlorine or UV radiation. Common sources of chlorine include chlorine gas and bleach or sodium hypochlorite. Chlorine contact basins are made with sufficient flow and volume control baffles to keep the liquid in place for at least 15 minutes before discharge. For aquatic life, chlorine is harmful. A reducing agent chemical, such as sulphur dioxide or sodium metabisulfite, is used to eliminate unreacted chlorine before discharge.

TERTIARY TREATMENT:

Processes that remove contaminants above and beyond the typical CBOD and TSS removal in secondary treatment are referred to as tertiary treatment. This includes increased TSS removal, total nitrogen, phosphorus, and ammonia. In order to adhere to ammonia and nutrient discharge limits, tertiary treatment is frequently necessary. Because biodegradable, organic suspended solids contribute to CBOD, their removal may be necessary to comply with strict CBOD or BOD discharge limitations.

- Nitrification and denitrification

- Removal of phosphorus by chemical precipitation and activated sludge process

- Filtration of suspended solids

Odour control methods:

- Chemical oxidation

- Combustion

- Thermal destruction

- Biological odor reduction

| Indian Standards for Disposal of Treated Effluents: Parameters | Inland Surface water | Discharge into public sewers |

| pH | 5.5 – 9.0 | 5.5 – 9.0 |

| Temperature (°C) | 40 | 45 |

| Color (Units) | 100 | – |

| Total Dissolved solids (mg/l) | 2100 | 2100 |

| Suspended solids (mg/l) | 100 | 600 |

| BOD5 (mg/l) | 30 | 350 |

| COD (mg/l) | 250 | – |

| Oil and Grease (mg/l) | 10 | 20 |

REFERENCES:

Bustillo-Lecompte, C., & Mehrvar, M. (2017). Slaughterhouse wastewater: treatment, management and resource recovery. Physico-chemical wastewater treatment and resource recovery, 153-174.

Food Science Australia, (2016). Meat technology – information sheet. Retrieved from < https://www.ampc.com.au/uploads/cgblog/id140/ENV_2006_Environmental-control-in-the-rendering-industry—1997.pdf>

Irshad, A., Suman, T., & Karthika, S. (2015). Current practices and emerging trends in abattoir effluent treatment in India: a review. International Journal of Livestock Research, 5(2), 13-31.

Johns, M. R. (1995). Developments in wastewater treatment in the meat processing industry: A review. Bioresource technology, 54(3), 203-216.

Sindt, G. L., & Engineer, P. E. (2006). Environmental issues in the rendering industry. Essential rendering, 245.