HOW TO PREPARE TOTAL MIXED RATION (TMR) FOR DAIRY CATTLE

Total Mixed Ration (TMR) can be described as a mixture of both the roughage and the processed ingredients, formulated and mixed to supply the cows requirements, in a form that precludes selection. It is designed to be the sole feed source given over a 24 hour period and fed ad lib. for optimum results. This cannot be accomplished without the use of accurate weighing equipment and adequate and proper mixing equipment (feed mixer wagon).

Now a day it’s the time for organized and big farms which needs feeding of animals precisely. Precise nutrition is possible with the help of TMR feeding concept. Organised farms should be converted to TMR feeding concept for improving the production performance of animals and also for economic rearing. While comparing the advantages and disadvantages of TMR feeding, always advantages are staying high. A carefully designed TMR feeding system in farms really payoff a lot. Good management of the farm should be coupled with TMR feeding for better productivity.

Dairy cow nutrition is very important for milk production and for maintaining proper health. Dairy cow feed should contain concentrates and forages in correct ratio. Adequate amount of nutrients, vitamins and minerals should be supplied to the animal. When the nutrients are balanced then only the animals can properly utilize it for better production and other vital functions of the body. Under these circumstances the concept of a single feed that had correct balance of all nutrients is getting importance. Total mixed ration (TMR) is an efficient and effective concept for feeding dairy animals for more profitable and productive purpose. A TMR is a completely balanced ration offered to cows in free choice. TMR feeding is a method of feeding successfully adopted for high yielding shed housed dairy cows all around the world. TMR comprises of forages, grains, protein feeds, minerals, vitamins and feed additives formulated to a specified nutrient concentration into a single feed mix. Two important things that had to be followed during preparation of TMR feed: Firstly regular testing of forages and other feed samples used in TMR for quality assurance and second thing is that the ration formulations had to be regularly updated based on milk quantity and quality parameters, body weight of animal, moisture conditions in forages and feed ingredients, price of feed ingredients etc. Like every feeding systems, TMR feeding method also had its own advantages and disadvantages.

The use of total mixed ration (TMR) in dairy cows is so widespread these days that we often forget there are still enterprises that rely on older feeding systems. Such was the case of my newest customer, a modest dairy farmer, who wanted to update his whole feeding system. When it came to designing a new nutrition program to match his modern genetics, the question came up whether we should also look into TMR feeding. As it happened, the exact cost of the machinery and extra labor were already known as a nearby farm had already adopted such technology. But, the big question was whether such investment was worth it and how fast it would pay itself back. In other words, what were the benefits of TMR feeding? In my opinion the benefits unfold in the following three-step process:

- Improved rumen fermentation. Cows have continuous access to a complete and balanced ration throughout the day. Thus, they tend to consume smaller but more meals per day, spread out evenly during their day. This prevents slug feeding that overloads the rumen with nutrients and unbalances the process. In contrast, rumen processes are optimized, digestibility improves, pH stabilizes and digestive upsets are minimized. This is because with each meal, the rumen microflora receive a balanced mix of all nutrients required for fermentation towards a desirable outcome.

- Increased dry matter intake. As digestive functionality and health are sustained at high levels, and in conjunction with continuous feed availability, cows consume more dry matter. Not only that, but they cannot pick out undesirable (unpalatable, dusty, etc.) ingredients, leading to much better efficiency of feed utilization and less residual feed. In addition, as the dry matter intake is easily monitored, nutrition can be easily adjusted to match genetic potential and actual performance, not to mention the ability to perform quick nutrition challenge on-farm trials.

- Enhanced milk production. As it can be anticipated, a healthy cow with a functioning rumen, free of digestive disorders, and exhibiting maximal feed intake will produce more milk — always assuming the TMR is balanced correctly, but this is a totally other story. How much more milk will be produced by TMR-fed cows is a question that requires some qualification. In general, if cows already produce well below their genetic potential, then it would not be reasonable to anticipate 2-3 kg more milk daily. On the other hand, if milk yield is already high enough, the estimate is around 1 kg more milk daily.

The TMR technology offers many advantages that lead to increased milk production. But, that’s not all of it. There are side benefits that can lead to decreased feed cost. However, this is a much more difficult exercise, and one that needs to be attempted after a farm is successful in implementing the TMR feeding system.

There are numerous challenges, all from a practical point of view, that arise as a farm adapts to this feeding system. Cows must be grouped and moved according to predetermined production phases. Feed must be pushed frequently to ensure animals do not sort the ration while feed is constantly available. Finding the right balance of ingredients and nutrients requires the input of an experienced nutritionist, and deciding how many different rations to mix is perhaps the most critical decision. Nevertheless, these are secondary challenges that are easily overcome by experienced staff. Perhaps, the most important drawback in TMR methodology is the cost of equipment and securing enough qualified labor force to operate the mixer and feed the cows.

Total Mixed Rations for Dairy Cattle

Feeding total mixed rations (TMRs) to dairy cattle is certainly not a new concept. TMRs have been fed for many years but recently there seems to be a greater interest in TMRs than ever before. This recent increase in popularity is somewhat regional but it seems that most areas of North America are seeing an increase in the use of TMRs.

TMRs are now widely used in areas of the India where large herd sizes are common. With large herds of production-grouped cows, often fed from bunk silos, TMR feeding becomes an obvious choice based on economics and practicality.

TMRs have been promoted in areas where both corn silage and haylage are fed since TMR feeding prevents individual cows from expressing a preference for one forage over another.

TMRs are used extensively in areas where seasonal calving is still common. With all cows at the same stage of lactation, the TMR for the whole herd can simply be adjusted as lactation progresses and grouping is not necessary.

Private consultants often promote TMRs in part because a TMR eliminates most commercial feeds from the ration making the farmer a better candidate for nutrition consulting services. A TMR also makes “commodity” and byproduct purchases more feasible, allowing the nutrition consultant to look at more ration options and make purchases on behalf of his client. A nutrition consultant who makes good purchasing and feeding decisions for a farmer can form an integral part of a successful TMR feeding system.

Although TMRs make the most sense in larger free-stall herds TMRs have been successfully adopted in herds of every type and size and the list of potential advantages makes them at least worthy of consideration for most herds.

POTENTIAL ADVANTAGES

ADVANTAGES OF A TMR

- Feed efficiency improvement is the core advantage of using TMR. Each bite or mouthful of TMR, which the animal consumes, is nutritionally balanced. This provides an adequate environment for the rumen microbes for their efficient functioning. Rumen microbes will be getting regular supply of carbohydrates and proteins for microbial protein production. This finally results in reduced metabolic disorders like acidosis, alkalosis, depressed milk fat, laminitis etc. · Selective feeding is reduced. Usually if we feed concentrates and forages separately animals had a tendency to eat whatever feed they like. This results in nutritional imbalance and digestive disturbances. In TMR feeding this option of selective feeding got minimized and adds to better feed utilization and efficiency. Increase in milk production is noticed upon TMR feeding. Because of better rumen fermentation, absence of metabolic disorders and apt supply of nutrients, milk quality also improves. Feeds which are hard to feed separately can be incorporated in TMR feed. So more byproducts and low quality forages can be included which in turn reduces the overall feed cost. · Labour saving is another important aspect. Feeding concentrates and forages separately will consume more time. · By knowing the correct amount of daily feed and dry matter intake, feed wastage can be prevented.

Increased dry matter intakes (DMI). Peak DMI is achieved 4 to 8 weeks earlier than conventional systems. Increased milk production by approximately 5 to 8%. Each additional kg DM consumed increases milk yield by 0,9 to 1,5l.

*Improved fat tests as a result of improved rumen fermentation, and optimal pH (acidity) levels of 6,2 to 6,8 achieved in the rumen, resulting in both maximal rumen fermentation and cellulose digestion leading to the formation of acetic acid, the precursor of butterfat production.

*Reduced digestive upsets due to each bite of feed having the same composition, minimising pH fluctuations in the rumen.

* Optimal protein synthesis in the rumen, as microbial protein synthesis is maximised at a rumen pH of 6,3 to 7,4.

*No need to feed mineral/vitamin supplements as all the requirements can be included in the TMR.

* Eliminate concentrate feeding at milking.

* A wider variety of less palatable feeds can be utilized in the ration as these are masked by the other ingredients by the elimination of selection.

*Better control of the cow’s diet.

KEYS TO TMR SUCCESS

- Forage quality must be good.

- Accurate weighing.

- Accurate moisture determination of feeds.

- Correctly balanced ration.

- Dry cow programme, i.e. adequate preparation.

Feed intake monitoring is absolutely critical.

(1) Of all feeding systems, a TMR most readily delivers a balanced ration to the cow, minimizing the difference between the ration as it appears “on-paper” and the ration that is actually consumed. In most other feeding systems the unknown of individual cow forage intake makes true ration balancing difficult. The delivery of a uniform TMR ensures that every bite consumed by the cow is the same, and is one of the strongest arguments in favour of TMRs.

(2) A TMR ensures a fixed ratio of forage:grain and also ensures that when two different forages are fed they will be consumed in the desired ratio.

(3) By providing an appropriate and consistent forage:grain ratio for early lactation cows, the management requirements of getting fresh cows onto full feed is simplified.

(4) A TMR results in a more uniform rumen pH than a feeding system that offers concentrates in meals. This helps to maintain milk fat test and also tends to improve feed efficiency and feed intake.

(5) Feeds such as fats or animal byproducts, routinely used in high production herds can present difficulties in traditional feeding systems due to their poor palatability but are easily fed in TMR system.

(6) Byproduct feeds such as wet brewer’s grains that may be impractical to use in more traditional systems often fit into a TMR system quite readily.

(7) Offering a TMR to cows in a free-stall barn results in cows standing less and resting more. Cows travel to one location to eat and have access to feed at all times. The extra time travelling to two feed sources – a bunk and a computer feeder – is eliminated and time spent waiting at a computer feeder is also eliminated.

(8) Since a TMR system eliminates the need for a commercially prepared dairy ration, a farmer switching to a TMR will automatically reap any benefits of a grain storage and milling system.

(9) A farmer feeding a TMR is more likely to analyze feeds and balance rations on a regular basis. This improves the chances of increasing milk production and income over feed cost.

POTENTIAL DISADVANTAGES

- TMR system of feeding is mainly for bigger farms because it is highly effective in group feeding instead of individual feeding. Separate TMR can be developed for different groups like fresh cows, early lactation, mid lactation, late lactation cows and dry cows. But certain disadvantages of group feeding are applicable to TMR feeding also. If a cow is having large variation in milk production or body weight from its group average, then this will result in under feeding or over feeding. · TMR method of feeding is more expensive since mixers/ blenders are needed for TMR preparation. Mixing should be proper because both over and under mixing causes problems. Under mixing causes less feed utilization. ·Chopping of hay/straw is needed for proper mixing sometimes.

(1) A factor that kept many farmers from adopting the TMR system was the general recommendation that cows be divided into at least two milking groups. In fact, in years past, many felt that three groups were required. This aspect of a TMR discouraged many producers from giving TMR much further thought. Today, specialists are more open-minded on this aspect of TMRs and would consider all of the following as possibilities, depending upon the individual farm involved:

(a) A three-group TMR is still sometimes recommended but is less popular. In many cases, the third group is for 1st-calf heifers.

(b) A two-group TMR is likely the most common in terms of use and recommendation. Again, the split may be based on mature versus 1st-calf heifers rather than on production level.

(c) One-group TMRs are now common. This approach can be successful in well-managed, high production herds where over-conditioning due to either low milk production or lengthy days open does not become a problem.

(d) Producers who are now using computer feeders may choose to use a one-group TMR, with the computer feeder reserved for high producing cows.

With this wide range of options now accepted and proven successful, the grouping aspect of TMRs is not necessarily the stumbling block that it was in the past.

(2) One of the most often cited disadvantages of a TMR is the milk production drop seen when cows are switched from one group to another. The extent of this problem will depend upon barn design – how different is one group’s facilities from the other? upon number of cows switched at a time – switching small numbers is more stressful than larger groups, upon ration difference from group to group – more than a 15 percent drop in energy content may cause problems, and the reason for moving the cow – if the cow is being moved strictly for space reasons but has not met an appropriate milk production or body condition criteria, then a production drop can be expected.

(3) On farms where forage quality is poor and refusals and significant feedbunk cleanout is common, one must bear in mind that on a TMR program this discarded feed will contain many high priced components in addition to the forage.

(4) Generally speaking, feeding a TMR is more time consuming than many other feeding systems. Someone must be present while ingredients for each group are weighed and mixed. This extra time requirement is partially offset since a TMR is usually fed only 2 times per day, in contrast to other feeding systems where multiple feedings are common.

(5) Much of what is written about dairy cattle nutrition is directed towards the individual cow. This includes reference to cow size, body condition, milk fat and protein test, an individual cow’s ability to eat concentrate and of course milk production itself. The TMR system does not cater to any of these factors on an individual cow basis and some would argue against TMR on this basis. The TMR system, by design, must deal with cows on a group basis rather than an individual cow basis.

With group feeding, individual adjustments in a cow’s diets for reasons such as sickness, poor body condition or boosting an individual’s BCA may no longer be possible.

Producers who have a TMR coupled with locking headgates or a computer feeder can cheat the TMR system and still give individual cow attention.

(6) Targeting of nutrients to individual cows is not as efficient in a TMR system. Depending upon the grouping system used, high priced ingredients such as rumen-protected fats or by-pass protein may be fed to cows who don’t require them.

(7) The inability to incorporate hay into a TMR was once seen as a problem but many TMR mixers are now capable of handling hay.

(8) A TMR program cannot be used when cattle are on pasture, thus limiting its usefulness in herds where pasture is still an important ration component.

(9) Feed analysis and ration balancing become even more important in a TMR system. Farmers who don’t carry out these tasks on a regular basis will not get best results. The dry matter level of the silage in the TMR is the most variable and most likely to introduce major errors into the ration if not routinely measured and adjusted for.

(10) Because one TMR mix is fed to a large number of cows, an error in calculation, weighing or mixing can have a much larger effect on milk production than in other feeding systems where errors are more likely to apply to individual cows.

MAKING A TMR WORK

The one rule above all others in successfully feeding a TMR is that the moisture content of the silages being fed must be routinely monitored and the ration adjusted accordingly.

For example, a TMR may originally be formulated to contain 10 kg of silage dry matter per cow. If the silage analysis indicates a dry matter level of 50% then each cow would be fed 20 kg of wet silage per day. If the silage further down in the silo contains only 30% dry matter and no adjustment is made, then the 20 kg of wet silage would now contain only 6 kg of dry matter rather than the 10 kg formulated for. This results in a 40% reduction in forage and a dramatic change in the forage:concentrate ratio. This shows how crucial on farm moisture testing is to the success of a TMR system.

Regular lab analysis of TMR components, especially the forage, is necessary if the use of nutritional safety margins are to be minimized and if income-over feed cost is to be maximized.

Although TMRs have been fed without the benefit of scales, one can’t expect anything but disappointing results from this approach. Accurate weighing of all dietary components is one of the cornerstones of a TMR feeding system.

To maximize dry matter intake and production, feedbunks should not be left empty for more than 2-3 hours per day.

TMRs that contain less than 50% dry matter may depress intake. Care should be taken to stay above this limit particularly in TMRs formulated for a high production group. A ration that is too wet is most likely to occur when high moisture grains and/or a wet byproduct feed is being fed.

There are no hard and fast rules regarding the production level that should be used as the balancing point for TMR formulation. Table 1 contains adjustment factors suggested by Virginia State University. For example, if half of the cows are in group 1 and half are in group 2 (50:0:50), then the recommended balancing point for the high group would be 1.17 times the group average and the balancing point for the low group 1.23 times that group’s average production.

Checklist for optimal intake

- Moisture content of 35 to 44% of the total diet.

- NDF and ADF content of forages checked to ensure correct fibre and ration intake.

- Correct feeding rates (ad lib), scale calibration and proper feed mixing.

- Feed 5 to 10% more than the cow is expected to eat.

- Limit unpalatable ingredients, e.g. tallow, poorly fermented silage, fishmeal, meat & bone meal, etc.

- A maximum of 50% of the ration moisture content derived from fermented feeds, e.g. brewers grain and silage. Ensure adequate trough space (900 mm/cow) and trough management, e.g. clean troughs, rain protection, shade, leaking troughs.

- Cow comfort, protection from heat stress or cold winds, e.g. shade or windbreaks.

- Adequate protein and salt levels in ration.

- Water quality and availability (up to 200 l/cow/day in hot weather).

To maximise DMI feed the ration in 4 to 5 portions over the day, avoiding rations with over 50% moisture. Ensure that the ration contains a minimum of 27% NDF or 19% ADF (DM basis), with 75% of the ration NDF derived from forage/roughage. Non-structural carbohydrates (NSC) should range from 38 to 40% of the DM for optimal rumen fermentation. Higher NSC levels can lead to lactic acid fermentation and acidosis, thereby reducing DMI. The ration should contain an optimal rumen degradable protein (RDP) to undegradable (UDP), or bypass, protein ratio of 60 to 40 to ensure adequate rumen fermentation, as well as adequate bypass protein for high production. Excess RDP will be detrimental to DMI. Include a maximum of half a kg of unprotected fat and half a kg of protected fat in the ration as excessive fat levels decrease palatability. The inclusion of feed buffers and a yeast culture is recommended to ensure optimal rumen fermentation.

EQUATIONS TO ESTIMATE DMI

General DMI (kg/day) = [1,8% x body mass (kg)] + [4% FCM (kg) / 3] where: 4% FCM = (0,4 x kg milk) + (15 x kg fat) (source: University of Minnesota)

Early lactation DMI (kg/day) = [0,01641 x bodymass (kg)] + [0,1713 x kg daily milk yield] + [4,534 x daily fat yield] Mid and late lactation DMI (kg/day) = Early lactation DMI x 1,07 (source: University of Wisconsin) DMI (kg/day) = [0,0185 x bodymass (kg)] + [0,305 x 4% FCM (KG)] (source: University of Georgia) If the expected and actual intake differ by more than 5 to 10% re-asses the “Keys to Success” and DMI checklist.

COMPONENTS OF FORAGE QUALITY

Factors affecting nutritive value

- ADF/NDF ratio

- CP and UDP (bypass protein) Factors affecting palatability

- Moisture, especially in fermented feeds e.g. silage

- Effective fibre (length)

- Heat damage of feeds Fibre components of the forage plant NDF is the chemical fraction determining the cell wall (or structural material) content of forages. It is the most accurate predictor of DM consumption. An increase in NDF content means poorer forage quality and reduced forage consumption by the animal. A percentage point increase in the ration NDF results in a 1,2% (0,45 kg) drop in the milk yield. A percentage point decrease in NDF (higher forage quality) will result in a 1,2% increase in milk production. ADF represents the relatively indigestible fibre in forage. It is a better prediction of energy content (digestible fibre) in forages than NDF. A percentage point increase in the ration ADF reduces milk yield by 0,3 kg per cow. A decrease in the ration ADF results in increased milk yield. The fibre (structural) and non-structural components of the forage plant cell are illustrated in Figure 1.

Rules of thumb for ration fibre

- Supply 2,5 kg long fibre (2,5 to 4,0 cm) per day for effective chewing of the cud and saliva production. § The physical structure of the ration is designed to ensure at least 26 minutes chewing time per kg DMI or 600 minutes of chewing time per day (10 hours). One third to half of the herd should be ruminating at any one time.

The physical structure of the ration is designed to ensure at least 26 minutes chewing time per kg DMI or 600 minutes of chewing time per day (10 hours). One third to half of the herd should be ruminating at any one time. § Supply 21 to 22% NDF (DM basis) from roughage, however, for a predominantly maize silage ration (>50%) 23% NDF from forages is required.

Supply 27 to 30% NDF in total ration dry matter. § Supply 19 to 21% ADF in ration dry matter. The impact of the forage NDF content on the percentage forage required in the ration to meet a 21% minimum NDF from forage is shown in Table 1.

NSC : RDP ratio

The NSC (starch, sugars) in the diet provides the energy required for microbial protein synthesis, ensuring microbial protein flow from the rumen to the duodenum. Fats and protein provide limited energy for microbial growth. However, when high levels of NSC are fed, insufficient ruminally degradable protein can limit microbial growth. Therefore, diets should be formulated to provide 35 to 40% NSC and 60 to 65% of the protein as RDP. It is critical that rations are formulated to promote microbial growth in the rumen. DMI declines when too much energy in the ration is derived from NSC or at high ration fibre levels which limit intake. A surplus of NSC (starch and sugars) in the diet may shift the ruminal fermentation pattern towards a lactic acid fermentation that would lead to acidosis and low fat levels in the milk. Guidelines for nutrient concentrations in TMRs The recommended guidelines for TMRs formulated for lactating cows, fresh in milk (0 to 21 days of lactation), early lactation (21 to 120 days), mid-lactation (120 – 220 days) and late lactation (>220 days) are given in Table 2, and for dry cows in Table 3. It is recommended that cows do not mobilize more than 1 kg/day and that they should return to a positive energy balance by 10 to 12 weeks post-partum i.e. they should not loose more than 60 kg, equivalent to 1 condition score for large cows and not to drop lower than a 1,5 condition score. Additional undegraded protein is required to utilize mobilized body reserves.

A pre-calving dry cow ration should include:-

- 2,7 to 4,0 kg DM of a bulky dry cow forage with low Ca & P, i.e. limited legumes or poultry litter

- a dry cow grain source to a maximum of 0,75 to 1,0% of the cow’s bodymass

- a dry cow mineral mixture

- 4,5 to 6,8 kg DM of the high Group TMR to allow the rumen to adapt to this mixture

- remove salt from dry cow ration

Do’s and Don’ts

- Purchase only those ingredients that can be used within 30 to 60 days.

- Don’t purchase a truckload of an ingredient that will last for a year or so as this will cost you money (interest/overdraft) and feed ingredients can deteriorate over time.

- Ingredients fed in small quantities or that require careful mixing are best purchased as part of a supplement, either a commercial product or a custom mix by a good miller.

- Non-persistent cows that are getting fat must be moved to a low energy ration or culled.

- Condition score · early lactation, minimum of 2,0 to 2,5 · drying off and calving 3,0 to 3,5

- The stress on the cows should be minimized where possible.

The following constitute stress conditions in dairy cows:-

· 2 weeks prior and 2 weeks post calving · cows losing over 1 kg bodymass per day · intake lagging behind output (negative energy balance) · first lactation cows producing over 30 kg FCM · heat and humidity · mud, snow or rain exposure · disease and metabolic disorders These stress conditions could have a negative effect on milk composition and milk production, as well as reproduction.

TMR feeding tips

- Chopping of fodder should be given due importance as fine chopping had to be avoided and also grain particles also should not be so coarse. Silage or haylage should have a particle size of ¾ inch. · Dry matter intake of TMR should be given utmost importance. Low intake of dry matter should be checked and immediate action should be taken to correct the same. Large changes in the dry matter of forages affect the total dry matter of TMR and also intake by animals. · Groping of animals based on production not only improve the efficiency of TMR feeding but also reduce the feed cost because feeding of expensive ingredients to lower producing cows causes extensive loss to the farmer · In a big farm ideal grouping can be done as follows 1. Lactating animals – High, medium and low producing 2. Dry animals – Early and close to calving 3. Heifers – Pre and post breeding 4. Calves · The left off TMR not taken by the animals should be only 5%.

Grouping guidelines for TMR feeding

Dairy herds feeding a TMR should have a minimum of three milk-production groups and preferably two dry-cow groups.

Suggested groups for a TMR-fed herd include the following:

- Pre-fresh or close-up dry cows (two to three weeks before calving)

These cows have a low dry matter intake (about 10 kg per day). They need a ration that is high in fiber and contains all the nutrients required to prepare for the impending birth of the calf, the initiation of lactation and help prevent metabolic problems. This ration should contain about 3 kg of grain, 2 to 3 kg of good-quality hay plus forage like corn silage and the proteins, minerals and feed additives needed to make the ration very palatable and help prevent metabolic disorders. - Fresh cow group (1 to 21 days after calving)

These cows have a low dry matter intake, but a high nutrient requirement as they begin the lactation. The ration should contain adequate fiber (2 to 3 kg of good- quality hay) to help promote good rumen function plus other forages and concentrates to get the cow off to a good start towards high milk production and moving into the high-production group. - High-producing older cow (2nd- lactation and greater) group (21 to 180 days in milk)

This group is where peak milk production and peak dry matter intake occur. The goal in feeding this group is to maintain a high milk production to get cows bred back for next lactation. This group can also be considered a reproduction group where heat detection and breeding occurs. - First-lactation or first-calf heifer group

First-lactation cows generally do better if they stay in a group of their own. This is due to social as well as nutrition reasons. They are slower to reach peak dry matter intake and milk production than are older cows, but more persistent in maintaining milk production than older cows. This group can stay together for 250 days in milk or more before moving to a late-lactation group. - Mid-lactation cows (180 to 250 days in milk)

Cows in this group should be pregnant and milk production should average 75 to 85 percent of the high group. The ration fed to this group should be higher in forages and slightly less nutrient-dense than the high-group ration. - Late-lactation pregnant cow group (250 days in milk to dry-off)

This group is where first-lactation cows, over 250 days in milk, can be mixed with older cows if barn space does not allow keeping first-lactation cows in their own pen(s) for the entire lactation. The ration will be high in forage with emphasis towards maintaining milk production and avoiding overconditioning or fattening cows. - Far-off dry cows (220 to 260 days pregnant)

The goal of the dry period should be to prepare the cow for the next lactation. The TMR should contain mostly good- to medium-quality forages to promote maximum rumen fill and rumination. Adequate protein and proper mineral balance in the ration is required.

Formulating TMR rations for groups

Rations should be balanced for slightly higher nutrient intake than what the average milk production of the group is. The dry matter intake (DMI) used to formulate the ration to the desired nutrient concentrations should be the same as the actual DMI of the group.

A general guide for lactating cow rations is to formulate them for milk production about 20 percent above the average production of the group. For example, if the group averages 26 kg of milk production per day, the ration should be formulated for 31 kg of milk per day. The DMI used to formulate the ration should be the actual amount of dry matter the group is consuming.

By formulating rations slightly above the average milk production, cows are changed to produce more and if they do not, the extra nutrition generally can be used for growth or added body condition. First-lactation cow groups can be formulated for 30 percent above actual milk production of the group to allow for growth of these animals.

Moving cows between groups

• After calving, cows should be moved first to the fresh cow group. Between 14 and 21 days after calving, healthy cows should be moved into the high-production group. Cows should remain in a high-production group until they are pregnant, milk production drops 10 percent or more below the average production of the group, or body condition scores of the cows are greater than 3.

• Cows will usually drop in milk production when moved between groups.

To minimize milk production drops, follow these guidelines:

– Move cows in groups of four or more. Individual cows are more affected by social changes and fighting in the groups than are groups of cows.

– Move cows at feeding time to minimize fighting and social disruptions.

– Move cows on a regularly scheduled basis. This helps cows get accustomed to moving and social changes.

– If within about five weeks of moving into the high-cow group or before 60 days in milk the cow does not reach the average milk production of the group, she should be moved to a lower production group.

– Try to avoid large changes in ration nutrient content between groups.

Drops in milk production resulting from nutritional changes can be minimized as cows move between groups by formulating rations for no more than a 9 kg milk-production difference.

Day-to-day TMR feeding

The success of a TMR feeding program requires the person feeding or the dairy manger to pay close attention to the following items. If these items are not closely monitored, cows will not consume the correct amount of nutrients necessary for good milk production, reproduction and health.

- Changes in feed dry matter

Rations for dairy cows are formulated on a dry matter basis and then the amounts of each feed fed are on an as-is or as-fed basis.

Knowing the correct dry matter (100 – % moisture) of ensiled forages and all other wet grains and feeds fed in the TMR is critical to the mixing and feeding of a balanced ration.

– Every dairy farm feeding a TMR should have a moisture tester. All ensiled forages and wet feeds should be tested at least once and preferably twice a week for moisture or dry matter content.

– Underestimating the dry matter content of a feed, assuming more moisture is present than there is, results in the feed being fed in a larger quantity than required.

– Overestimating the dry matter of a feed, assuming less moisture is present than there actually is, results in feeding less of the feed than required.

– Feeders and dairy managers feeding a TMR can be alerted to changes in the dry matter content of feeds through:

1. Changes in the size or volume of the TMR mixed

2. Cows having larger-than-normal amount of feed remaining the next day (usually indicates feeds have increased in dry matter)

3. Cows having no feed remaining the next day (usually indicates feeds have decreased in dry matter content or increased in moisture)

- Know the correct number of cows in the group every day and feed for that number.

Daily counts of the number of cows in a group before feeding is necessary so the correct amount of feed fed per cow is attained. - Increase or decrease the amount of TMR mixed according to daily variations in feed intake.

Cows do not eat exactly the same amount of feed every day. Weather conditions and environmental temperatures have a big effect on daily feed intakes.

When adjusting a TMR for daily intake variation, move the amount of all feeds up or down in proportion. If feed intakes remain consistently 5 percent or about 2 kg as-fed more or less than the original amount the ration was balanced for, the ration should be reformulated using the new changed feed intake amount.

- Add feeds to the TMR mixer in the proper order.

– In mixers with augers, grains and other concentrate mixes are generally added first followed by ensiled forages and dry forages last. With auger mixers, dry forages are best chopped or ground coarsely before being added to the mixer.

– In vertical mixers with one or two center augers, dry or long forages are generally added first, followed by grains, concentrates and then ensiled forages such as corn silage.

- Do not overmix the TMR.

Mixing times will vary with the type of mixer, auger or vertical, amount of feed in the mixer, size of the tractor running the mixer and the condition, new or old, of the mixer.

In general, mixing five minutes after the last feed ingredient has been added should be sufficient time to mix the load thoroughly. With vertical mixers, final mixing time after all ingredients are added often is only three to five minutes.

If the TMR is overmixed, the particle size is reduced and no long physical fiber remains in the TMR. This will lead to rumen upsets, low cud chewing and acidosis.

- Number of times and when to feed the TMR per day

A TMR can be fed once per day, but twice per day is preferable especially during hot, humid summer months. Feeding twice per day, once in the early morning and once in the evening, keeps the feed fresher and encourages feed intake.

Many dairy producers feed the TMR while cows are in the parlor being milked so they return to the pen to fresh feed. This is when cows are usually the hungriest and eating encourages cows to stand, allowing the udders to dry off and teats to seal before lying down.

- Push feed in several times per day.

The TMR should be pushed in towards the pen six or more times per day. Cows eat the feed closest to them first.

They can only reach out about 72 centimeters from the pen to get feed. Therefore, if feed is not pushed in toward the pen several times per day, the cows that are less aggressive may not be able to maximize their feed intake.

Pushing feed in several times per day is very important when pens are overcrowded and feedbunk space is less than 46 centimeters per cow.

- Watch for sorting of the TMR.

Cows are effective at using their noses to sort through a TMR, separating the grain from the forage. Cows will usually eat grain first and leave long forages for a second meal later.

By doing this, cows unbalance the TMR, consuming only grain at one meal which can lead to acidosis and off-feed problems. The drier the TMR, the more the sorting.

A TMR should be between 50 and 55 percent dry matter. Feeding the TMR more frequently than once per day or pushing feed in often helps reduce sorting problems.

- Observe feed refusals each day.

The feed remaining in the bunk just prior to feeding the new TMR should look like the TMR about to be fed.

If there are long forage particles, corn cobs or other noticeable large amounts of any single feed ingredient, this indicates cows are sorting and not consuming a balanced ration. Either chop the long forages or particle feeds finer or replace them in the TMR with feeds that are more difficult to sort.

- Check particle size of the TMR.

Every two to four weeks, the particle size of the TMR should be checked. Use a Penn State Particle Size Separator box to check.

The goal is to have 6 to 10 percent of the TMR feed on the top screen, 30 to 50 percent on the middle screen, 30 to 50 percent on the lower screen and less than 20 percent of the feed in the bottom pan. Having a lot of long particles in the TMR or more than 10 percent on the top screen allows cows to sort the TMR easier.

- Calibrate mixer scales once every three months.

Mixer scales should be checked when the mixer is at one-third, two-thirds and full weight capacity. Placing a known amount of weight (25 to 45 kg) on each corner of the mixer at the three weight loads is an easy effective way to test the scales.

Table 1 Adjustment Factors for TMR Formulation*

| % of cows in each group | Production Group High Medium Low |

||

| 100: 0: 0 | 1.32 | – | – |

| 70: 0: 30 | 1.22 | – | 1.21 |

| 50: 0: 50 | 1.17 | – | 1.23 |

| 30: 0: 70 | 1.14 | – | 1.25 |

| 33: 33: 33 | 1.14 | 1.10 | 1.21 |

| 25: 25: 50 | 1.13 | 1.07 | 1.23 |

| 25: 50: 25 | 1.13 | 1.14 | 1.21 |

| 50: 25: 25 | 1.18 | 1.08 | 1.21 |

* Multiply group’s average production by the appropriate factor to determine balancing point.

Balanced ration is a prerequisite for successful dairy farming. An animal of high genetic potential will become a medium milk producer if feed is not properly balanced. When the feed is not properly balanced, it leads to low milk production, lower growth in heifers, impaired reproduction and low immunity. In Punjab, the majority of farmers keep animals under mixed farming system doing both crop production and animal husbandry. Such farmers rely more on crop residues like wheat straw and paddy straw for feeding to animals. Crop residues are inherently low in essential nutrients and animals subsisting on these produces lower quantity of milk. On the other hand, the farmers who take dairy farming as their main profession tend to feed more balanced ration and their milk production per animal is higher. Before formulating a balanced concentrate feed, the following points need to be kept in mind:

- Type of forage being fed – Non legume fodders are low in protein but high in energy whereas legume fodders are high in protein, calcium and phosphorus but low in dry matter

- Quality of forage fed – Mature, dry fodders are low in digestibility and in energy and other essential nutrients

- Milk yield and milk fat % of the target animal

- Stage of lactation and body condition score – In late lactation, animals with good body condition score (3.0 or above) require less energy in their ration

- Body weight of the animal

- Age of cow, whether first calver and growing or mature cows

Advantages of TMR feeding

TMR is a feed for dairy animals, in which green fodder, especially silage is mixed along with concentrate in proportion and composition, to make it a balanced ration for a particular group of animals. Thus, in ruminants the mixing of roughage and concentrate portion of the feed as a blend i.e. TMR, has several advantages, like;

- It is very suitable on silage-based feeding system.

- It maintains rumen pH in favorable range (above 6.0).

- The incidence of lameness in the herd is reduced.

- Animals eat balanced ration in every bite.

- There is an increase in fat % in milk and also milk yield by 3-5%.

- The unpalatable materials can be mixed in TMR at higher proportions without affecting the intake of animals.

- Feeding operation can be mechanized, thereby reducing the labor requirement.

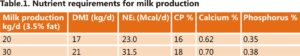

Cow’s requirement for nutrients

Cow’s requirement of energy, protein, calcium and phosphorus depend upon body weight and milk production.

To calculate the energy required for 20 kg milk with 3.5% fat.

0.70 Mcal NEL/kg milk x 20 = 14

9 Mcal is required for maintenance for 500 kg animal

Total requirement is 9 + 14 = 23 Mcal NEL/d. For first lactation animals, we have to give growth allowance also. For 500 g/d growth, 2.4 MCal NEL and 320 g/d protein is required. This will add in addition to the requirement for maintenance and milk production. Protein requirement for milk production is 85 gm/kg milk in cows.

Environmental temperature also plays a role in energy requirement. Exposure to cold increases the energy requirement of the animal.

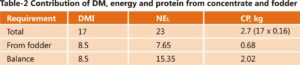

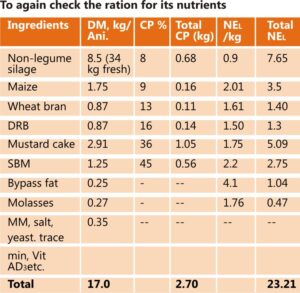

The starting point in balancing the dairy cow ration is to know the quantity and quality of green fodder/silage/hay. For example, if we have green sorghum silage at optimum stage of harvest, it will have 25% dry matter, 8% crude protein and 0.9 Mcal NEL/kg DM. In early lactation, we fix forage concentrate ratio at 60: 40 for medium yielders (approx. 4000 kg milk/lactation) and 50: 50 for high yielders (approx. 6000 kg milk/lactation). Taking the example of a cow having 500 kg body weight and producing 20 kg milk per day, we can proceed in the following manner:

DMI = 17 kg/d (Table-1)

From Green fodder = 8.5 kg

(50% of DMI)

Crude protein from green = 8.5x 0.08 = 0.68 kg

Energy = 7.65 MCal NEL

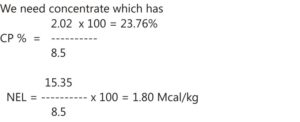

For making concentrate mixture of required crude protein per cent, Pearson square method can be used. It is described below:

Pearson square method

First fix the

ingredients 2.0% bypass fat

1.5% mineral mixture

1% salt

4.5% molasses

0.5% buffer

0.1% toxin binder

0.1% yeast

0.05% chelated trace minerals

0.25% limestone powder

Total = 10

These 10 parts of concentrate will not supply any protein, therefore, balance 90 kg should contain 23.76 kg crude protein

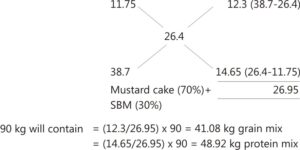

Then select energy ingredients like maize, wheat bran and deoiled rice bran. Give weighted value to calculate the crude protein % of these energy ingredients. Here we have taken 50% maize, 25% wheat bran and 25% deoiled rice bran. The crude protein per cent in these are 9, 13 and 16%, respectively. The average CP of grain mix will be

(50 x 0.09) + (25 x 0.13) + (25 x 0.16) = 11.75%

Similarly, protein mix of mustard cake is (70%) and soybean meal (30%) having CP % of 36 and 45%, respectively. Their average CP will be 38.7%.

Then applying the Pearson square method:

Maize (50%) + Wheat bran (25%) + DRB (25%)

Grain mix required:

Maize = 41.08 x 0.5 = 20.54 kg

Wheat bran = 41.08 x 0.25 = 10.27 kg

DRB = 41.08 x 0.25 = 10.27 kg

Protein mix required

Mustard cake = 48.92 x 0.7 = 34.24 kg

SBM = 48.92 x 0.3 = 14.68 kg

The final composition of concentrate mixture Parts per 100 kg

Maize 20.54

Wheat bran 10.27

DRB 10.27

Mustard cake 34.24

SBM 14.68

Mineral mixture 1.5

Salt 1.0

Buffer 0.5

Toxin binder 0.1

Yeast 0.1

Chelated MM 0.05

Molasses 4.5

Bypass fat 2.0

Limestone powder 0.25

Vit Ad3 0.5 gm

The quantity of concentrate ingredients per animal per day was calculated by taking proportion of each ingredient from 8.5 kg daily concentrate allowance. For example, the above concentrate contains 20.54 % maize in it. The daily maize intake by the animal will be 8.5×0.2054=1.75 kg.

If we take DM level (92% approx.) in to consideration then

8.5

On as such basis the conc. offered /ani/d = ——= 9.24 kg

0.92

Feeding of TMR to milking cows

- Feed TMR twice in summers during cooler hours of the day.

- In winter one-time feeding could be practiced.

- Make sure that there is always 2-3% residue left in the manger which could be fed to dry animals.

- Check the quality of silage from lab periodically.

- It is difficult to design a TMR on green fodder because the quality changes frequently but on silage-based feeding system the quality of roughage remains similar for longer periods and accordingly calculation could be done.

Properly balanced ration not only increases the milk production but also lowers the cost of milk production as well as it provides balanced ration with higher efficiency of conversion of ration DM to milk solids. On an average, the dairy ration should be balanced on fortnightly basis depending upon change in milk production and quality and quantity of available green fodder.

(This article is a work of many dairy consultants and is for public information purpose only. This has been written to share knowledge on dairy nutrition and is not a legal information or statement. Reference to any specific product or entity doesn’t constitute an endorsement or recommendation by the company.Reference will be given on request)