Impact of Modern Poultry Farming Innovations on the Poultry Sector Growth in India

The adoption of agri technologies has matured in India to a large extent. The poultry industry has witnessed monumental numerous transformational technological adoptions. This translates to enhanced traits in terms of egg production, growth rate, livability, disease resistance, feed efficiency and egg and meat quality. Modern tech enables a higher rate and persistence of egg and meat production, better feed efficiency, egg size, egg quality, muscle mass, carcass quality, feed efficiency and livability in boilers. The country’s poultry sector has shown immense growth which is reflecting in its ongoing operations. The sector can be marked as one of the fastest-growing sectors of the country with its trade wheels helping India to build a stronger economy. India ranks third in egg production and fifth in meat production with a total population of 851.81 million (20th Livestock Census, 2019) which reveals an increase of 16.8 per cent over the previous census i.e. 729 million.

Egg and chicken are wholesome, nutritious food with high nutrient density because, in proportion to their calorie count, they provide the required amount of daily protein and a wide variety of other nutrients. They are rich in vitamins, essential amino acids and minerals such as vitamin A, B6, B12, folate, iron, phosphorus, selenium, choline and zinc etc. However, currently, India’s poultry sector is going through a transitional phase from being manual to digital. Apart from increasing the production capacity of this sector, this transformation is likely to enhance the quality of the output. With the demand of eggs and poultry meat rising in India, this transition cycle can be considered as the right card placed on the gambling table.

In the last two-three decades, a lot of technology along with orthodox breeding methodologies has been infused into India’s poultry sector to genetically enhance traits such as egg production, growth rate, livability, disease resistance, feed efficiency and egg and meat quality etc. The significant impact of modern technologies can be seen in the layer and broiler segments of the poultry industry. The technologies used support higher rate and persistence of egg and meat production, better feed efficiency, egg size, egg quality, muscle mass, carcass quality, feed efficiency and livability in boilers.

The Poultry sector is a most important segment of the livestock industry. This sector consists of many different levels of production, including breeding farms, hatcheries, feed factories, , broiler and layer farms and proczessing plants. Likewise, there are sub-units such as chicken, quail, duck, turkey, guinea fowl and goose in terms of species in the sector. In terms of infrastructure, different types of housing from thatched shed to automated, environmentally controlled sheds, normal feeders to automatic feeders and regular channel watering systems to automatic cups and nipples, automatic egg collection, refrigeration systems, nutraceutical and medicine manufacturing units, vaccine manufacturing units, manufacturing mechanical components to electronic gadgets required for various functions. Rendering plants and production for feathers. Therefore, it involves all the derived sciences such as physics, chemistry, biology, biotechnology, and other engineering skills. There is enormous growth and progress in this sector and the sub-classes for production are divided into meat and egg production. All these have gradually grown from back yard to industrial proportion over six decades (1960 to 2020) owes to veterinarians, poultry scientists, technical and non- technical persons and dedicated farmers.

With all the developments yet there is organized and unorganized sectors in poultry in our country. Organised sub-sector needs conducive environment to grow for which policy support & intervention is required mainly for disease surveillance, drug residue and drug/ vaccine quality control, standardization & quality control of poultry feed, eggs & meat, application of HACCP (Hazard Analysis and Critical Control Point) and Good Manufacturing Practices (GMP) for compliance to WTO & CODEX norms and gradation, value addition, brand promotion & export boosting etc.

By the end of this decade, globally, poultry meat is expected to represent 41 per cent of all the protein from meat sources, according to the OECD-FAO Agricultural Outlook 2030.

The Indian poultry industry is poised to benefit from the ongoing changes in lifestyles in general and eating habits in particular. No wonder, the share of organised commercial farms is rising as it is largely modernized and technically improvised.

According to government data, egg production has been rising steadily, having risen from 95 billion in 2017-18 to 105 billion the following year and to 114 billion in 2019-20. Similarly, poultry meat production, too, has been expanding. from 3.7 mmt in 2017-18 it grew to 4.1 mmt the following year, and then on to 4.3 mmt in 2019-20.

Although ambitious, some projections suggest, by 2023, the country may produce 136 billion eggs and 6.2 ml t poultry meat.

The global poultry market reached a value of nearly $319.2 billion in 2019, having grown at a compound annual growth rate (CAGR) of 5.5% since 2015, and is expected to grow at a CAGR of 6.1% to nearly $405 billion by 2023. The market is expected to grow at a CAGR of 7.2% to nearly $465.7 billion by 2025, and at a CAGR of 6.8% to $645.7 billion by 2030.

Change in the farming systems

The progress in is all sectors of poultry is due to the advancement of technologies in the management, nutrition and health care systems. Over the years, the successors of farmers now are with highly qualified and having double degrees, Technical / engineering and even medical and veterinary professionals. Therefore, the poultry industry is now in the hands of well leaned and educated groups. They always think differently and adopt any technology available globally for the benefit of profitability. These are not only innovators but also have open mind to accept and adopt any innovation that are useful in modern poultry farming. The new farming systems are called “Smart farms, Automated farms, Mechanized farms and Digital farms.

New Trends in Poultry Farming

Two years ago ( March 11, 2020) the World Health Organization formally declared a pandemic caused by a novel coronavirus. And as COVID-19 spread across the globe, humanity had little time to adapt to lockdowns and staggering losses.

The COVID-19 pandemic has severely affected many economic sectors across the world, including livestock production. It has also sparked fears of an impending economic crisis and recession. Disrupted production and transportation, declining consumer demand and volatile markets brought huge financial difficulties, even leading to the permanent closure of many farms. Social distancing, self-isolation and travel restrictions have led to a reduced workforce across all economic sectors and caused many jobs to be lost. Schools have closed down, and the need for commodities and manufactured products has decreased. In contrast, the need for medical supplies has significantly increased. The food sector is also faced the increased demand due to panic-buying and stockpiling of food products. More than the above, the problems started in labour management and this lead to adopt new innovative ideas in poultry farming. In short 2020 was a critical year- COVID-19 posed numerous challenges for the poultry industry, from worker shortages to interruptions throughout the supply chain. The New technologies can help the industry solve these issues and look forward to future opportunities to thrive and succeed. This paper deals with the adoption of several such advances and innovative products for a successful poultry farming.

The following are emerged as some of the new trends in poultry Farming:

- Is there a genetic solution for preventing male chicks?

- 3D cameras could capture precision broiler weights

- MRI technology can help identify which eggs are fertile

- Could smartwatches solve poultry processing’s labor problem?

- 24/7 feedback loops could improve poultry flock outcomes.

- Collaborative robots could further poultry automation

- In-line poultry chilling could be improved using kinematics

- Preventing antibiotic resistance in poultry using peptides

- Digital technologies set to simplify poultry data analysis.

- Hyperspectral imaging could help find poultry meat defects.

- Machine vision can detect broiler floor distribution.

- Will CRISPR transform the poultry industry?.

- Robots are ready to meet poultry processing challenges.

- Automation helps prepare case-ready poultry for the future.

- Digitalization can optimize poultry productivity planning

- Healthy chicks establish adult poultry microbiome quickly.

The Technologies that could disrupt future production and processing operations are:

- Remote sensing

Remote sensing allows visibility in real-time on a number of factors, conditions within the poultry house, bird performance, bird health and welfare. Not only is it the case that the farmer can keep watch over the status of sheds and birds when they decide to take a look at the computer but importantly the readings from these sensors can be set to provide “alerts” to management if any parameter falls out with the agreed requirements for the specific age of birds 24/7.

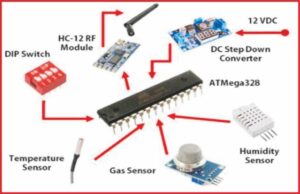

- Sensors can help streamline the data collection process for both birds and workers, resulting in precision poultry production.

- Application of the smart phones helping the owner to monitor real time environmental contexts such as temperature, humidity, ammonia gas, water level.

- In this system describes an Integrated Solution for Smart Poultry Monitoring Using WSN (wireless Sensor Network) and GPRS Network.

- For example, in poultry, sensors can be used to help estimate body weights and measure the flock uniformity.

They can also help solve labour issues and improve worker retention and food safety when used as a wearable sensor for employees.

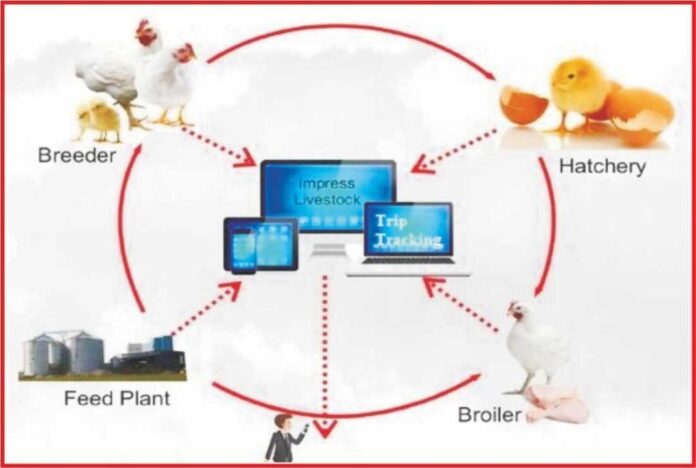

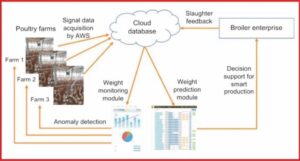

Fig:1.Use of gadgets at different stages of poultry operations

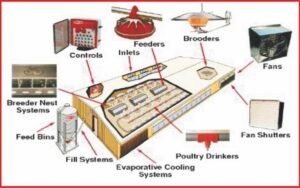

Fig:2. Automation and use of internet to measure the data generated in different houses

- Automation and Digitalization, Big data: a major value chain in poultry Industry

- Automation can be used to replace manual labor on poultry farms when it comes to repetitive tasks like checking bird welfare, removing welfare, vaccinations and managing litter.

- In processing plants, there are robots that can cut meat from the bones, which could help space out workers at risk of COVID-19.

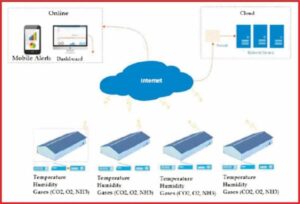

- The integration of wireless sensors and GPRS network to control and automatically monitor environmental parameters in a poultry farm.

- The environmental parameters like temperature, humidity, ammonia gas control etc.

- The person in-charge can able to get the internal environmental situation of poultry farm by receiving a message on registered mobile number

- Robotics and automation

Robotics and automation generated intense interest for their potential to reduce labor, be on duty 24/7 and report remotely. Robotic technology can encourage broiler breeders and layer hens to move around the house, reducing the incidence of floor eggs and stimulating fertility, improving bird health and welfare and reducing the amount of labor required. The robot can save up to 50% of a farmer’s time, reduce the number of trips by two-thirds and improve working conditions.

Fig:3. Robots in poultry operation

Robotic technology that uses artificial intelligence to help farmers make data-driven decisions about broiler production could result in a healthier, more productive growing environment. Use robotics to encourage the birds to be more active to increase muscle mass, which ultimately drives better improvements when it comes to the feed conversion ratio.

Robots offer not only increase productivity and profits but their presence can also contribute to improved health and welfare. Some robots will continuously scratch the litter to eliminate caking and wet spots, reducing the incidence of pododermatitis, foot burn and breast burn(fig4). Others can monitor and map ammonia, temperature and humidity levels throughout the house. This is valuable information for producers who can adjust ventilation and address any localized issue that may affect bird welfare or productivity. These corrections can prevent a localized issue from affecting the entire flock.

a). Collaborative robotic technology : is one of the most popular new trends in automation.

Collaborative robots, also known as ‘cobots’ are designed to work safely alongside human workers. Typically, the robot is responsible for any repetitive task, freeing up the human worker to perform more complex, thought-intensive tasks. The robot that navigates poultry house floors using imaging sensors and machine learning, has the capability to detect and pick up floor eggs and sense environmental temperatures, gasses and light levels. Robots can free up human workers to perform more complex, thought-intensive tasks, streamlining operations.

Some of the benefits of Cobots include:

- Cost-effective approach to simpler applications

- Improved ROI calculation for low-speed applications

- Ability to implement robots into space constrained applications

- Shorter programming time

- Quicker deployment

b). Chicken Boy, an autonomous ceiling-suspended robot incorporating artificial intelligence and sensors, assesses ambient conditions, health and welfare and equipment failures. Already on the market in Europe, developers at Farm Robotics and Automation planning to continue adding capabilities including removal of dead birds and analysis of litter moisture.

- Monitor poultry floor distribution with machine vision

Fig 4: Smart poultry production and data recording for anaysis

In commercial bedding floor poultry houses, bird density and distribution pattern are critical factors for evaluating production management and animal health/welfare. Currently, daily routine inspection of broiler flock distribution in commercial grow-out houses is done manually, which is labor intensive and time consuming. This will also indicate how a machine vision-based method can monitor floor distribution of chickens in drinking, feeding and resting/activity zones. This study provides the basis for developing a real-time evaluation tool to detect broiler chicken floor distribution patterns, behaviors and welfare indicators in commercial production facilities.

The egg sector also has its fair share of applications for AI. The quality of the egg white for instance, the absence of any trace of yolk – is important for many applications requiring optimum egg white foaming. Modern breakers operate at very high speeds, in the order of 200,000 eggs per hour or roughly 60 eggs per second, making it impossible for the human eye to detect an issue.

a). Artificial Vision: In poultry processing the use of artificial vision offers real-time yield monitoring of high-value chicken parts, allowing supervisors to immediately give feedback to employees who can address any potential deficiency. Artificial vision also constitutes a standardized method that can be used to compare results between workers, shifts and processing plants, particularly valuable for large companies operating across multiple sites. Artificial vision can also be combined with smart automation to optimize efficiencies; for example, where broiler parts are automatically sorted after inspection. For processors, AI allows higher processing speeds and accurate packing of premium value products, translating both into more profits and fewer customer complaints. Researchers are now looking at means to totally replace human intervention for some specific tasks considered painful or hard to achieve accurately and consistently.

b). Woody Breast Detection with machine vision and high-speed cameras is capable of detecting and/or sorting breast fillets at normal line speeds without contacting or damaging fillets. Muscle rigidity is measured as the fillets move on and fall off a conveyor.

c). 3D Bird Deboning Cutting Virtual Reality generates cutting trajectories for automated poultry processing systems. It is under development at Georgia Tech Research Institute. Testing started with models but now is on real birds.

Fig: 5. automation in checking o f meat and eggs.

d). Food safety

Food safety is a critical concern in the poultry business, and the innovations. This needs to be addressed both the live production and processing stages. All the above technologies developed ultimately help the production of safe food for human consumption.

- Technicon Composite-housing Gearboxes

with steel endoskeletons eliminate rust, dissipate heat and withstand wash-down processes. Housings are corrosion-resistant and blended with an antimicrobial material that does not exhibit odor or staining in harsh environments. Market launch is perhaps two years away, and prices of the composite gearboxes are expected to be competitive with units with painted cast-iron housings.

- Clear Labs Next Generation Sequencing

Using advanced data analytics and bioinformatics tools for detection and serotype identification of Salmonella spp. in samples taken from carcass rinses, ground poultry, poultry parts, boot swabs and equipment swabs. The system’s accuracy reduces inventory holding time and delayed shipments, confirmation costs and delays, and retail short-supply penalties.

- Big data and artificial intelligence

Harnessing the increasing amounts and complexity of data available to the poultry enterprise is not only a daunting task but a huge opportunity (fig. 6 and 7).

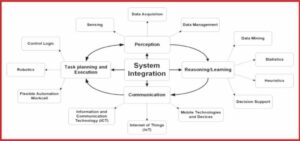

Fig 6. Data generated by breeders, Hatchery, Feed plant and Farms are computerized

Fig:7. System integration in poultry operations

- Artificial Intelligence(AI)

Artificial intelligence, when applied to broiler and egg production, may not only improve efficiency but help producers address following challenges.

- Scientists are now teaching machines how to recognize any sound of distress or discomfort to aid in monitoring bird wellbeing.

- Another area with great potential for AI is its use in detecting early stage disease.

- AI has the potential to assist in detecting diseases during their incubation period, allowing producers to quickly prevent spread throughout a flock.

- AI can also help with disease diagnosis.

- Using AI to complement or augment the human brain – collaborative intelligence – will give us the potential to be more efficient and accurate in diagnoses.

- Other areas for AI include feed formulation optimization, genetic selection and hatchery management.

- All segments of the poultry sector will be able to benefit from applications using AI.

- Using advanced artificial intelligence software, integrators can find solutions through data that would otherwise difficult to perceive.

- New artificial intelligence technology can help integrators save money and get better flock performance by facilitating investigation and decision making.

- Little Bird Feed Cast System

This estimates the amount of feed in on-farm bins using a small device to apply vibration to the bin surface along with sensors and software. The solar-powered units wirelessly report feed levels via web portals and a mobile app to growers, feed mills and integrators. The web portal presents a history of a house’s feed levels and displays projections. Feed outages are reduced or eliminated and less feed is reclaimed at the end of a flock.

- Poultry System Simulation Model ( PYSSM) :

Simulates the water, energy, wastewater and labor utilization of a poultry processing plant. Based on VENSIM [http://vensim.com/vensim-software/] software, the model simulates all processes that require water use. Designed by developers at Georgia Tech Research Institute as a decision making tool with predictive capabilities, there are modules for labor, water, energy and wastewater processes.

- Machine Learning: Statistical Process Control (SPC)

Uses machine learning and historical location-based data as well as plant-level outcomes to dynamically model the live operations supply chain, predict outcomes and apply outcome scores. It allows quicker and more accurate identification and response to potential changes in variables that impact food safety or production outcomes throughout the poultry supply chain.

- How Audio -Analytic -Software detect respiratory disease

- New analytical software can detect symptoms of laryngotracheitis, infectious bronchitis and potentially other diseases as well as welfare issues.

- Thanks to machine learning techniques, audio software can help farmers detect sick birds before they can.

- The two diseases IB & ILT are primarily detected by a farmer present in the house who hears the coughing of the birds.

- The amount of days that pass after an outbreak are critical in the progression of the disease and its potential damage to a flock.

- If there were a way to automatically detect it instead of waiting for a farmer to randomly encounter it, it could make detection of the disease and treatment quicker. Create a hardware and software system to detect and recognize the specific sounds of an avian cough symptomatic of the conditions among the noise of the poultry house.

- The research was able to identify certain auditory shapes in the sonic spectrum of the house that correlated with the coughs. The next challenge was to teach a machine to recognize those shapes and share the detection with its user.

- Simple Vet Regulatory Compliance Data Management

This applies Blockchain technology to veterinary records to maintain transparency and traceability while also providing analytics to evaluate efficacy of treatments. A suite of integration tools integrate data sources, including public and private block chains, traditional databases and systems and internet-of-things (IoT) enabled devices such as RFID tags and remote sensing technology.

- Block Chain Technology (Value Chain Management)

Uses predictive analytics and deep learning analysis to display and forecast future performance throughout the supply chain. An integrated view of operational data allows finished product to be traced back through the value chain at a minute level of detail. The cloud-based platform uses block chain technology and deep learning neural networks to monitor poultry operations at large scale and across regions.

- Block chain’s opportunity in the poultry industry is its ability to resolve food safety and transparency issues. Walmart, Unilever, Nestlé and other food giants are working with IBM using block chain technology to secure digital records and monitor supply chain management, ensuring traceability of the poultry products sold in stores.

- Block chain can be used to monitor all aspects of the food supply chain, from farmers and producers to processors and distributors. This is Walmart’s third experiment with block chain, and the increasing interest of other large food conglomerates demonstrates the unique capabilities of this technology.

- Transport Genie

Records micro-climate conditions of live poultry during transport, including real-time communications with the driver and key stakeholders. If a threshold is exceeded, an alert is sent automatically. The sensor can be used by processors to improve bird welfare during the loadout, in transport and in plant holding sheds.

- Gene Editing Technology (egg XYT CRISPR )

Inserts a bio-marker in the DNA of male chicks at the parent stock level to create an optical signature in embryos detectable at the breeding/hatching operation. Upon scanning of incoming eggs, those with male embryos are diverted to food production. A pilot study in a poultry layer flock is planned for late 2018. Developers are said to be in negotiations to incorporate the technology in the stock of a major breeding company.

- Microbiome and Life sciences

Advancements in genetics, microbiology, poultry health management, nutrition and more help improve flock management to raise healthier birds. In human medicine, the microbiome has been linked to everything from intestinal health to obesity and mental disorders. Scientists are now applying these findings to poultry, developing probiotics to help control Bacterial and protozoal diseases and to improve the immunity.

a). Edible Vaccines enable chicken producers to dose room-temperature stable vaccine in the feed for both mucosal (in the gut) and systemic (intracellular) protection against coccidiosis. The technology platform inserts genes for specific antigens into corn plants to create the vaccines.

b). Phytogenic Blends for Coccidiosis Control chemically block receptors specific to parasites and physically disrupt the parasite cuticle. The blends are composed of GRAS-listed terpenes that naturally occur in food plants known to be safe as food flavorants. Using a proprietary encapsulation technology, the formulation will be active in the intestine of the chicken.

c). General Probiotics Antimicrobial Probiotics are genetically modified microbes for use in the feed or water of poultry that can detect pathogens and secrete antimicrobials against pathogens, secrete multiple antimicrobials lowering resistance emergence and/or secrete engineered antimicrobial lysins. Prototypes against Salmonella, Campylobacter and Clostridia have been developed. The company expects to complete regulatory requirements and bring the products to market within three years.

d).Nutritional Technology: Digital tools like artificial intelligence (AI) can help poultry producers optimize the decision-making process when it comes to feed management and assessing the health of the gut microbiome. AI-powered tech can provide recommendations how to improve the feed composition to recommendations to improvements in farm management practices with the goal of improved performance and health of the flock.

The nutritional research focus, henceforth, will be influenced mostly by the following innovations:

- Feed formulation software and feeding programmes

- Novel feed ingredients and feed additives

- Gastro-intestinal conditioners for gut health, birds’ welfare and food safety

- Modern technologies for feed processing and feeding packages

- Perinatal nutrition and epigenetic programming

- Advances in AI could lead to a better understanding of the poultry gut microbiome.

- In recent years, the microbiome has captured the attention of researchers, who have linked the microbial makeup of the gut to a variety of poultry diseases and other conditions affecting flock health.

- The health of the gut microbiome, a collection of microorganisms present in the gastrointestinal tract, can be affected by changes in raw materials, diet, additives, vaccine programs and farm management practices.

- Techniques of in-ovo-nutrition

A combination of statistical analysis, machine learning and AI can work together to create insights and recommendations on the status of a flock’s microbiome, based on data from a non-invasive cloacal swab-sampling of live birds. Producers can use this information to determine what actions to take to improve flock performance.

18). Nanotechnology for virus detection

Nanotechnology plays a pivotal role in the mechanism of tracking virus entry. The single virus tracking technology (SVT) makes it possible to track the different stages of a single virus in its life cycle, thus providing dynamic insights into the basic process of virus occurrence in living cells (Liu et al., 2020) It help in trap avian flu viruses for early detection.

Biosensors have come up with a lot of promises in terms of detecting viruses and diseases connected with them. The development of various types of such biosensors such as Affinity-based Nano-biosensors, Nano island affinity-based biosensors, Graphene affinity-based biosensors, Nanowires based biosensors, Optical Nano biosensors, Fiber optic Nano-biosensors, Surface Plasmon Resonance (SPR) based optical Nano-biosensors, Total internal reflection fluorescence, Surface-Enhanced Raman Scattering (SERS), Electrochemical Nano-biosensors had helped us in the rapid and sensitive detection of viruses. Aid to these Nano sensors, viral detection now becomes very sensitive, rapid and cost has come down to a significant low. In this review, an attempt has been made to compile all of the different Nano-biosensors and their applications. Due attention is given to the fact that the reader gets the grasp of the concept with much ease.

The following components, which make up the new revolutionary technologies, are classified into them.

Poultry Breeding

Scientific breeding for desired qualities is one of the most efficient ways to improve the performance of chicken flocks. Today, hybrid vigour or crossbreeding is used to create poultry lines with outstanding performance. Different commercial birds are developed by crossing between traitspecific purebred lines to produce broilers and layers. These crossing lines come from the great-grandparents of public use commercial birds. By commercial poultry breeding and selling companies, purebred lines, great grandparents, grandparents, and parents are typically maintained. The following are some recent advancements in poultry breeding technology. QTLs are used to choose the sire and dam for the following generation. Every characteristic is a reflection of a few proteins that were created using the genetic code found in the form of genes in DNA. Quantitative trait loci, or QTLs, are groups of genes in avian DNA that are strongly associated with a particular attribute of interest, such as body weight gain in the case of broilers. Therefore, this approach is employed for continuous variable qualities that are the outcome of numerous DNA genes. Microarray study, which is the analysis of microscopic slides with organized series of animal sample, is used to identify the genes for our trait of interest. The qualities that are currently profitable can be found on DNA using this approach. Many procedures, including transgenesis, shutting down a gene with RNAi and proteomics, nanotechnology, epigenetics, in-ovo approaches, and even CRISPR gene editing technologies, are now employed to add new features or characteristics to poultry strains or reduce the malfunctioning of a gene. The introduction of new traits that are not present naturally is aided by these procedures. The performance decline in birds caused by extreme weather conditions can be partially or entirely reversed with the aid of novel gene editing technologies. For instance, the introduction of a single gene that reduces or modifies feathering allows the naked neck strain of chicken to successfully handle heat or temperature.

Nutrition of Poultry

As over 70% of all expenses in chicken production go toward feed, it has a significant impact on the industry. 95% of the overall cost of the feed is spent on the purchase of the energy and protein-containing feed ingredients. Minerals, vitamins, and feed additives get the remaining funds. Therefore, a key aspect in poultry production is feed. The most popular feed item for poultry diets is maize, while soybean meal is the most popular feed ingredient for adding protein. For the most part, compounded feed is used for poultry. The following new developments in the usage of feed components in chicken production have recently occurred. New transgenic feed is created with the help of transgensis that contains more essential proteins and amino acids for chicken. These transgenic feed also contain fewer tannins and glycosinolates than conventional feed, which includes canola meals with low erucic acid. Due to their limited appetite, poultry birds can only consume a certain amount of feed, making it difficult to provide the proper balance of nutrients. These transgenic feeds are a technique to now supplement the diet of poultry with additional vital elements. Synbiotics with probiotics and prebiotics are currently being used as new antibiotic alternatives, particularly for drugs that affect on gut bacteria. Synbiotics aid in enhancing the healthful microbial activity and survival in the gut. The limited supply of amino acids produced in feed ingredients is prepared using new biotechnological methods. Through the metabolic process of microbes like yeast, these are created. These microorganisms can manufacture these limited amino acids because their genomes have been modified to include particular genes. These microbes may create even tract minerals like zinc, manganese, chromium, selenium, copper, etc.

Health of Poultry

The second largest expense in running a chicken farm, behind feed, is health care. Diseases like bird flu, fowl pox, and others can quickly spread throughout a whole flock and cause the death of all the birds on a farm. Therefore, the well-being of the birds is crucial for successful farming. A new batch of birds is often introduced into the facility after every bird in a flock has been sold, which is known as the “all-in and all-out” technique in poultry production. New birds are properly quarantined before being added to breeding stock or any other stock. For the benefit of the health of birds, biosecurity precautions should also be taken. Here are a few modern methods for fighting infections in chicken farming. Birds are now treated for a variety of ailments right away, and the causes of those diseases are thoroughly investigated so that in the future effective preventative measures can be applied. Post-mortem examination of deceased birds and epidemiological research on diseases are crucial for this. Another very crucial factor is whether the infectious pathogen causing the sickness is the same or a newly developed strain. A treatment plan or preventative strategy should then be implemented at the chicken farm. The disease-controlling strategy of chicken farms includes infrastructure for disease diagnosis, training of farm staff, and information sharing on newly emerging diseases. Diseases like the bird flu and others can be fought by creating disease-free zones surrounding poultry farms using a variety of tight biosecurity procedures. A disease prevention campaign against area-specific infections, together with a vaccination programme, can be prepared with the aid of a geographic information system (GIS), a computer system for capturing, storing, verifying, and displaying data connected to positions on the earth’s surface.

Housing for Poultry

Housing for poultry includes avian facilities and farmingrelated machinery. The equipment used by poultry is impacted by advances in mechanics. Since commercial poultry farms account for 62% of all poultry farms worldwide, where poultry equipment plays a significant role, home poultry farming is likewise shifting toward commercial farming. Here are a few recent advancements in poultry housing. Modern farms are adopting new automated control systems with automated showers and the usage of cooling pads that are simple to clean and disinfect. New moving chain feeders are employed for effective feed distribution, quickly completing the circuit. Modern farms frequently use flicker-free fluid LED lighting systems with adjustable light levels. Special digital air quality monitors are used in poultry farms to track the levels of ammonia and carbon dioxide in the facility where the birds are housed. These monitors provide real-time readings of these gases. By doing so, the toxicity of these gases is reduced, which helps to preserve the performance of birds. The new water system is meant to stop dirt, faeces, and other contaminants from getting into the automatic drinking system, keeping water clean. This aids in preventing both water waste and water-borne illnesses in flocks. Manure collection in layer farming uses a specific moving belt system. After that, palletization of dried manure further stabilises the substance, lowering agricultural dust. This aids in keeping the poultry farm’s conditions clean. Farmers are able to observe their broiler sheds interior from their cellphones, tablets, and personal computers with the use of remote access livestock monitoring systems used in poultry farms. This might be advantageous for farm management in the current COVID-19 environment.

India’s economy is heavily dependent on the poultry industry. The improvement of rural livelihoods through poultry farming is crucial for rural development. The need for animal protein in the form of meat and eggs is rising as the world’s population rises day by day. Given that India is the world’s third- and fifth-largest producers of eggs and poultry, this may present a significant potential for farmers of poultry. But this won’t be possible unless and until Indian farmers adopt new technologies related to contemporary chicken rearing. These contemporary advancements in poultry farming can help Indian poultry producers succeed and prosper.

Modernisation of packaging to reduce wastage

Egg, being a fragile product, understandably, needs extra care while being transported. A rough figure suggests that around 20 to 25 per cent of eggs produced in the country get wasted during the transit. It is mainly due to two reasons either packaging or condition of roads. In order to reduce wastage, many companies including startups have come up with multiple packaging solutions that provide extra cushion to the produce.

Packaging, an innate segment of the polymers and advanced materials industry, has been witnessing significant evolution in the terms of manufacturing technology, over the past few years. The manufacturing technology across the packaging sector has massively improved to the point that the final products can boast of a much smoother surface and more sophisticated feel and look.

There two major stages of packaging eggs go through before they end up in the hands of customers. In the first stage, when the egg is transported to the dealer, it requires extra cushion because of its freshness so most of the farmers use walled basket packaging which is filled with odourless rice husks, wheat chaff or chopped straw. Another form of packaging used in this stage is called filler tray packaging, filler trays are made of wood pulp moulded to accommodate the eggs. They are constructed so that they can be stacked one on top of the other and can also be placed in boxes ready for transport. Filler trays also offer a convenient method for counting the eggs in each box, without having to count every single egg.

On the second stage, when eggs reach dealers’ cold storage and need to be transported to distributors, most of them are packed in hard moulded boxes in combination of six and 36 eggs in a pack.

Vacuum packaging for longer shelf life

Extension of the shelf life of meat and poultry products is one of the technology needs to meet the demands of consumers and vacuum packaging (VP) can be considered as one of the aces to enable industry to achieve this goal. Vacuum packaging refers to packaging in containers (rigid or flexible), from which substantially all air has been removed prior to final sealing of the container. This method of packaging is actually a form of ‘modified atmosphere’ since normal air is removed from the package.

Shan Kadavil, Co-Founder and CEO, Fresh To Home stated, “Vacuum packaging helps the traders and the customers to retain packed food for a longer time. For instance, usually a processed chicken in normal packaging can be retained for a maximum three days but with vacuum packaging, its shelf life increases to 15 days. It is possible as this type of packaging avoids bacteria proliferation and avoids useless food waste by promoting much more responsible food consumption.”

Echoing a similar voice, Siddhant Wangdi, Founder and CEO, Meatigo stated, “Apart from retaining freshness of the product for a longer time, VP protects the product from freezer burn and dehydration. Freezer burn occurs when air comes into contact with water crystals around food. Vacuum sealing helps prevent this by keeping the air out of contact with the food. Freezer burn is not a danger to one’s health, however, it ruins the taste and texture of the food.”

There are some other advantages of VP such as it reduces storing space, enhances the taste, no chemical preservatives required, saves money on bulk orders, reduces wastage of food, and is quick and efficient.

Smart poultry farms with IoT

The Internet of Things (IoT) which has done wonders in many businesses and trades can prove a real catalyst in fostering the country’s poultry sector. IoT solutions give real-time access to information, bring speed to business operation, save ample time and help many industries overcome their major challenges. Similar usage of IoT in the poultry sector will help breeders and farmers to switch over from orthodox manual farming methods to smart poultry farming solutions.

An intelligent network and data processing system can create a new poultry farming infrastructure in India. With the help collected data on a real-time basis, farmers can monitor the health of birds, their growth scale, amount of feed to be given and other necessary steps to be taken in future.

Like any other sector, data management plays a vital role in the poultry sector. The data of broiler farms include the number of birds, feed, mortality, production, and much more. By embedding IoT solutions in their farm, farmers are well equipped with a system that can record the data, store it, and process the historical data for any query or information.

Adopting a similar concept, an IoT startup, MLIT, devices a system called PoultryMon that works with incubators at the hatchery and at the farm and allows remote monitoring and management. Launched in 2017, the system has provided a much needed technological assistance to the hatchery owners as its sensors provide real time data on temperature, humidity and other required information to the hatchery workers and owners.

Conclusion:

The growth of poultry farming can be visualized from its expansion from initial stage and transformation to industrial proposition over a period of six decades(1960- 2020). Thanks to the dedicated private poultry suppliers, farmers, technicians and poultry scientists who stood at every level of its growth facing many challenges and finding the salvations from time to time. The advancement in science in every field is fast approaching and specifically its application in poultry production has caught the attention of many learned poultry farmers. The automation has given boost to increase the operational capacity to many folds. A simple example is change over from deep litter to cage system, to present environmentally controlled units and introduction of automated feeding and watering systems. Currently application of computer based technologies in feed formulations, egg and meat production has generated a big data on all operations. Automation can be used to replace manual labor on poultry farms when it comes to repetitive tasks like checking bird welfare, vaccinations and managing litter. However, the latest technologies will change the future farming systems if they are used properly looking in to the economic implications in adopting newer technologies.

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.

POULTRY SECTOR OF INDIA CAN PLAY A PIVOTAL ROLE IN SOLVING THE PRESENT ECONOMIC SLOWDOWN CRISIS