Indian Dairy Sector is Transforming with Tech-Innovations : High Tech Dairy Farming with Application of Advanced Technology

Technology has greatly enhanced dairy farming processes making them easier and simpler. This, in turn, has lowered dairy farming costs as compared to other years. Currently, the number of dairy products in the market has greatly multiplied as a result of advancement in dairy farming. Therefore, advancement in technology has affected dairy farming positively.

Latest technology in dairy farming performs a number of functions like recordings daily milk yields, monitoring of milk component such as protein and fat, pedometers, recording temperature automatically, indicating milk conductors, detecting of estrus in an automatic manner and finally taking daily measurements of the animals’ body weights.

The respective kind of technologies has greatly caused impacts in quality, healthy and reproduction control. The major benefits associated with these are reduced costs, improved quality of products, increased efficiency, reduction of the adverse environmental effects and improved performances in the health of dairy animals and their general well-being.

Technology has enhanced the growth of dairy cattle in a correct and healthy manner. In addition, it has helped in boosting of milk production and monitoring of these herds. For instance, the use of drone technology has been effectively used to monitor dairy animals. This is because the drone works to ensure that everything is in its right location. It makes this possible by flying over the properties.

Another important form of latest technology in dairy farming is the issue of computer farming system. This system works by using facial recognition software to monitor cows. This is vital in helping to give out physical information including the invisible one.

Also, other dairy farmers nowadays have adopted the technology of robotic cow milking equipment which does the work repetitively and precisely. The latest technology is applied here to make the work effective every time for the purpose of attaining and maintaining the required standards.

There is also another important latest device used in dairy farming called the Delavan swinging cow brush. This play a major role in ensuring that the cattle are comfortable during their rotations. The brush helps to stimulate blood circulation which keeps the cows healthy and comfortable always leading to a high quantity of milk production.

Moreover, dairy farmers have adopted a way of keeping track of the cow’s health, milk production levels and the number of cows which have already been milked. This is made possible through the use of sensor technology which provides information to the farmer through a transporter.

Furthermore, nowadays farmers access apps which have built up and made their operations even easier as compared to other periods. This app allows them to get access to skills that are so essential in addition to finding the potential market for the products mostly online markets.

Currently, farmers are looking for alternatives to power sources as opposed to electricity as one way of making farming operations easier than before. This, in turn, will promise continuous production of dairy products. One way of making this process successful is through the use of solar panels to generate power to their homes.

Finally, another form of latest technology in dairy farming is the use of dairy shed technologies. This one has been used effectively in increasing the quantity of production. For instance, the use of automated cup removers and spraying and automated drafting. Also the introduction of automated mastitis detection system which plays a vital role in making detection of diseases.

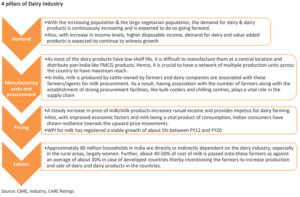

Animal husbandry is one of the most lucrative and demanding businesses not only in India but across the globe. The livestock sector — within it, dairy — needs to play a larger role in the prime minister’s goal to double the farmer’s income by FY23. Dairy farming in India contributes to 4% of its GDP. CARE Ratings estimates milk production to have increased by about 3.9% in FY20 to reach 195 million tonnes. Also, between FY19 and FY23, milk production is expected to increase at about 4.8% CAGR to reach 226 million tonnes by FY23 while the per capita availability is expected to witness a CAGR of about 4.6% during the period to cross 470 grams per day by FY23. India has also retained the leadership position in milk production by producing 188 mn tonnes in FY19; accounting for about 22% of global milk production. Hence, dairy industry has played a crucial role in the agro-based Indian economy.

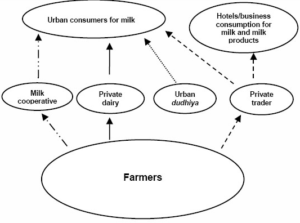

Overview of dairy marketing channels in India

India’s milk consumption is the highest in the world and accounts for 26% of world consumption. Estimates suggest that 48% of the milk produced is consumed by dairy farmers themselves, and 52% is marketable. A study undertaken by a private agency has estimated that of the total surplus, 20% is processed in the cooperative sector, 30% by branded private dairy companies, and the rest by the unorganized sector (milk for sweet shops, loose milk, etc). Uttar Pradesh, Andhra Pradesh, Rajasthan, Gujarat, Maharashtra, Madhya Pradesh, Haryana, and Punjab together account for 65% of the country’s milk production. The processing capacity, measured in terms of milk chilling infrastructure (cooperatives), is highly skewed, with Gujarat alone accounting for 46% of this. Future growth of dairy must come from newer areas, and with modernized technology suited for small dairy farmers.

National Action Plan for Dairy Development includes the introduction of exotic cows, cross-breeding, and the improvement of nutrition and hygiene. The plan aims to increase daily output per cow to 7.1 kg by FY 2023, equivalent to 1.5 times the FY 2015 level.

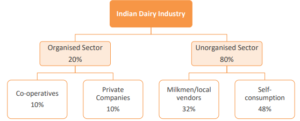

Structure of Indian Dairy Industry

Source: Dept. of Animal Husbandry, dairying & fisheries, Ministry of Agriculture & Farmers Welfare, GOI

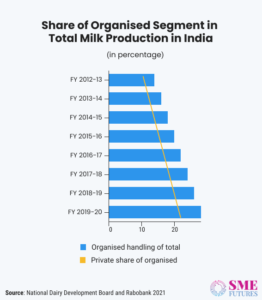

The unorganized segment consists of traditional milkmen, vendors, and self-consumption at home, and the organized segment consists of cooperatives and private dairies. In most of the developed nations, 90% of the surplus milk is processed through the organized sector. With the increase in population, rise in per capita income, changing lifestyle, affordable aspirational food habits, export opportunities, etc., the demand for milk is expected to rise. As per the Department of animal husbandry and dairying, it is estimated that the demand for milk would be in the range of 200–210 million tonnes by FY22. As per the Department of Animal Husbandry, Dairying and Fisheries, the organized milk handling is expected to grow from 20% at present to 50% by FY23.

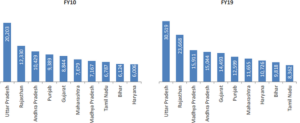

State-wise milk production (000 tonnes):

Source: National Dairy Development Board (NDDB)

The top 10 states of milk producers have continued to remain constant over the last few years accounting for a share of over 80% in the total milk production in the country. In FY10, Madhya Pradesh ranked 7th in milk production and it has moved up to 3rd position in FY19, while Punjab has moved to 6th position, down from 4th in FY10.

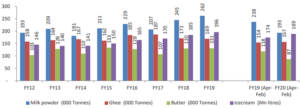

Dairy Products:

Source: CMIE

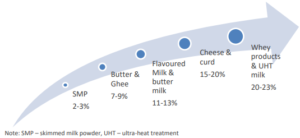

During the last five to ten years, India has seen dramatic shift towards the consumption of value-added products such as cheese, yoghurt, UHT (ultra-heat treatment) milk, flavored milk, and whey. To tap the advantages of the changing consumer food preferences, most organized players are expanding product portfolios in the value-added segment. This segment offers high growth potential and better margins versus the liquid milk and Skimmed Milk Powder (SMP) segment.

The value-added products market is under-penetrated, thus having tremendous scope for growth and is expected to grow at much faster rate as compared with the commodity market. The private players are also investing in brand-building exercise and aiming to add more B2C business in their portfolio. The value-added products overall contribute to ~35–40% of the total dairy market in India and commodity products together contribute to almost ~65% of market share. Furthermore, within the value-added segment, largest product category is ghee, having a market share of about 15–18% in the overall dairy market. While loose packets of curd is available locally, a key characteristic of emerging value-added products like UHT milk, flavoured milk, low-fat curd/yogurt, cheese and whey is that 100% of these products are sold through organized market. Average margins for value added products across categories shown below-

Few Indian Major Players are as under

AI and future of dairy:

Nowadays emerging technologies affecting agriculture in the long run to optimize management and profitability. The implementation of robotic milking machine brushes for added cow comfort, and automatic calf feeders on dairy farms across the country and world going to revolutionizing the dairy sector. Imagine a data system that monitors your cows’ activities 24 hours a day, 7 days a week from lameness and estrous detection to dry matter intake (DMI). With a new technology that recognizes each cow in the barn, this dairy farmer’s dream becomes a reality.

Cainthus is the technology company that created the cow facial recognition system that monitors cattle via cameras located on the roof of the barn. The data is then sent to a server on the farm. The main goals are to utilize the data to maximize production and limit stress levels on the cows.

There are many uses for the artificial intelligence system that can be customized for the dairy farm’s needs. For example, the system detected that the cows are eating three to four hours a day. The efficient adjustment of herd’s feed rations and dairy tour routes based on information. In addition, limiting pen moves for cattle helps keep feed intake consistent across the herd.

How technology is changing the dairy industry?

Nowadays, farmers no longer spend hours hand milking each cow one by one, thanks to the advent of the relevant technology, which has drastically changed the functioning of Indian farms and dairies. Over the last few decades, such advancements in technology have allowed dairy farmers to improve the everyday quality of life of their herds as well.

According to the Ministry of Food Processing Industries, the capacity created by private dairies in the last 20 years is more than the capacity set up by the cooperatives in over 30 years. It’s all because of the advanced high-tech setups in private farms. Which indicates that development is proportionate to tech-adoption.

Director at Mr Milk by Mittal Happy Cows Dairy Farm, Neeraj Mittal says that technology adoption is imperative for them to improve their operations,

“The use of technology has definitely helped us grow faster. Technology has also reduced our dependency on manual labour and especially during the pandemic, technology has helped in making sure our delivery process has been smooth,” he asserts.

Neeraj Mittal, Director at Mr Milk by Mittal Happy Cows Dairy Farm,

Mittal’s farm in Maharashtra is fully equipped by Swedish tech brand DeLaval, who have planned and installed the technology at the farm for them. While their software partner is Indian dairy-tech startup Mr. Milkman. “Technology has been a great helping hand to the dairy industry and at the Mittal Dairy Farm,” he says as he feels that it was all because of the automated processes in the farm, that they and other farms like them could keep going during the pandemic.

Citing the example of his own farm as it is entirely automated, he tells us about the processes where dairy farms are leveraging technology, “We use an automated milking system through which the milk is directly stored in the milk parlour at a certain temperature and directly packed into milk cartons that are recyclable and eco-friendly. We maintain the delivery process through our software; hence we can assure our customers of the timely delivery of our products. Also, our app is extremely user friendly. Our customers can place their orders and pay directly on the app,” he clarifies.

Similarly, a leading private dairy label, Hatsun Agro, which already has 18 processing units, has recently set up a 19th fully automated dairy processing plant in Solapur (Greenfield Dairy) with imported equipment from Germany. According to an official, the plant will process 6 lakh litres of milk per day (LLPD).

Additionally, the setting up of this plant will help onboard dairy farmers to the mainstream network and will boost the income of over 75,000 to 90,000 dairy farmers in Maharashtra.

Having said that, it’s not only the co-operatives, private or large farms that are getting tech-savvy, but small dairy farmers too are now utilizing modern dairy processes.

A small dairy farm owner, M. Sharma who has over 30 cows of a native breed in Greater Noida, says, “The technologies have the potential to change the way we manage cows.”

Sharma has been milking his herd using a herringbone milk parlour, which not only saves time but also saves manpower, money, and allows them to monitor the freshness of the milk. Sharma feels that since its inception, his business has grown significantly, and he is now supplying and delivering unadulterated A2 milk and milk products to at least 50 + customers.

“I believe that technology is present in all aspects of dairy operations. From feeding to milking to herd tracking. Today’s technological solutions are more advanced, allowing us to better manage our farms and animals. As a result, disease losses are reduced, longevity is increased, and animal well-being is improved,” he adds.

In another instance, Akash Patil, the owner of Motake dairy farm in Maharashtra, uses technology to monitor his cow herd’s health. According to him, using technology-based tags eliminated the need for labour, manual intervention, and guesswork in determining the heat and health status of an individual cow or a group, which has only increased the value of his revenues.

This suggests that technological interventions in dairy operations are not only making their lives easier but also increasing the farmer’s incomes, which is the government’s ultimate goal by 2022.

Technology has opened more avenues

Experts also agree on the fact that it was mainly due to technological interventions that the sector was barely impacted by the pandemic. In fact, it turned the crisis into an opportunity in many ways—there was more SMP production, it aided the formalization of the dairy sector, and the players went online.

According to FAO data, India’s milk output reached 195 million tonnes in 2020, up 2.0 per cent from 2019, underpinned by the continued rise in dairy cattle numbers and improved feed and fodder availability due to favourable monsoon rains (June to September).

When consumption and sales of dairy items were witnessing a dent, the cooperative model and private companies in India went out of their way to protect the milk producers.

They kept procuring milk resulting in surplus supply and channelled it to drying plants for the manufacturing of skimmed milk powder. Which actually is a whole new gamut of technological processes (pasteurizing, heat treatments, drying and more) and can be considered as a different industry within the dairy sector. We can, however, say that the fast mobilisation of the village cooperatives’ network facilitated milk output growth.

In what seems like a record production of skimmed milk powder, India doubled its production in just one and a half month during the lockdown. The figures of NDDB reveal that on March 15, the stock of milk powder was 70,000 metric tonnes.

On the flip side, due to going online and relying heavily on technology in the dairy business, the unorganised dairy segment was greatly diminished.

“There was a clear and rapid shift in milk collection from the informal to the formal channel at the farm level immediately after the lockdown, with farmers delivering more milk in the organised collection centres of private companies and cooperatives. The informal milk market disappeared almost completely from April to June 2020, and it is attempting to recapture its market share. However, even before COVID-19, there was a movement towards organised milk markets that became more pronounced during the pandemic,”

says Shiva Mudgil, Research Analyst at Rabobank, on the emerging trends in the Indian dairy sector.

The dairy industry adopted and shifted to various new methods and processes, including major technological interventions, in response to the changing trends thrown up by the pandemic.

To summarise, consumers’ emphasis on quality, safety, and hygiene prompted farms to implement technological solutions to cater to their customers who work from home. These changes were implemented from the shop floor to the management level, and included the adoption of online payment, e-commerce, and e-logistics solutions.

Meanwhile, many companies have established new business channels and partnered with retail and online delivery start-ups such as Bigbasket, Milkbasket, Supr Daily, and others. Dairy companies, in fact, are attempting to increase their engagement with QSR chains that have highly developed online and take-away business models. Take, for example, Domino’s India.

Another emerging trend is that of sustainability, in which stakeholders are working together. Farm owners are now making continuous efforts to implement sustainable processes in their operations, whether it is in chilling the milk, packaging it, or reducing spoilage. This is pushing farms to partner with innovative start-ups.

“Technology will play a crucial role in augmenting sustainability by way of data collection, analysis, and adoption of tools than can leverage the chain’s maximum benefits, starting with the dairy farmers. Stellapps, Promethean Power, and Inficold are some of the companies working on this concept,” states Mudgil in the Rabobank analysis.

Why dairy needs technology?

Meanwhile, it’s important to note that unlike in the West, India’s dairy industry is highly unorganised. Which means that about 60 per cent surplus milk is handled by the unorganised sector (milkmen), while the remaining 40 per cent is procured by the organised sector comprising of dairy co-operatives and private companies. In developed countries, about 90 per cent surplus milk is handled through the organised sector.

According to the experts in the field, due to the highly unorganised nature of the sector, technological advancements have been minimal. In fact, a lack of technological adoption has created a slew of other issues for the sector.

Some of these challenges are—high wastage and inconsistent quality and quantity of milk for many small farmers.

According to Chambers of Commerce and Industry of India (Assocham) and MRSS estimates, about 3 per cent of the milk produced gets wasted annually.

The volume of the wastage, coupled with the increased demand for dairy products, may hamper India’s plan to produce about 300 million tonnes of milk by 2024.

In addition, the average milk yield of cows in India is lower than that of their American counterparts—1,248 kgs of milk per cow in a year compared with ~10,000 kgs of milk per year. Indian dairy farmers must increase production and focus on reducing wastage to meet their targets.

“The Indian dairy industry is mainly based on the collection module as farmers are unable to manage a bigger herd. People are now preferring single sourced milk to make sure of its hygiene and quality. With the right kind of technology, small scale dairy platforms can grow their farms and assure customers about the purity of their milk,” says Mittal of Mr. Milk. According to him this will aid the sector in mitigating the wastage of milk.

At the same time, even if India is the largest milk producing nation, because of its large cattle population, it doesn’t have high milk productivity.

“One of the bottlenecks hindering the growth of milk productivity is the lack of a technology-based system of production in rural areas,”

opines Pravin Kini, Founder & MD, Tropical Animal Genetics.

According to him, 80 per cent of Indian cattle are owned by farmers with a herd size of up to four animals with little automation and infrastructure. Moreover, the poor genetics of the herd also leads to low milk productivity.

Parallel to this, the appetite and demand for dairy products is on the rise too.

According to the National Dairy Development Board (NDDB), the demand for milk and milk products will surge up to 266.5 million metric tonnes by 2030.

This is owing to the growing urban population, an expanding middle class with a high disposable income, and consumers seeking out healthy food options. The advent of COVID-19 has also triggered a change in the consumption pattern of dairy products including curd, paneer, ghee and other cheese variants.

However, the supply side is not yet equal to this challenge of fulfilling this ever-growing demand.

According to Kini, the demand for milk is growing at 6 per cent annually in India but supply is growing at only 4 per cent. “To meet the increasing demand for milk and ensure that India is self-dependent about milk production, there needs to be more productivity. Hence there is a need for a second white revolution. The gap between this supply and demand can be addressed by adopting innovative dairy farming practices,” he opines.

Also, most of India’s dairy presence remains in rural areas which lack a continuous and reliable power supply. Here, milk chilling is one of the major hurdles for farmers.

According to experts such as Shridhar Mehta, Director at Prompt Equipments, an Ahmedabad based dairy tech firm, “I fathom that the majority of milk collection centres also do not have cooling infrastructure such as chilling centres, cold chains, or bulk milk coolers. Which can be a huge challenge for them. Whereas solutions to instantly chill milk are available, we just need more efforts for their higher adoption.”

But on the other side, it also presents a huge opportunity for the dairy segment, according to Mehta.

As per the projections of the government’s National Action Plan, there is a requirement of 8,80,000 rapid milk chillers in India, and this translates into a $3 billion opportunity.

Another challenge for India is to enhance its export share in the global market.

Currently, India’s exports share in the world is meagre—0.36 per cent.

The goal is to take this share up to 10 per cent. Another aim is to double the processing capacity from 53.5 million metric tonnes (MMT) to 108 MMT by 2025. The government, in its roadmap for 2025 for the dairy sector also aims to increase value added products from 23 per cent to 40 per cent.

India’s export of dairy products to the world was 51,421.85 MT, worth Rs. 1,341.03 crores or US$ 186.71 million during the year 2019-20.

Adulteration is yet another very prominent issue for the milk sector.

Milk is tainted either intentionally or accidently during the production and processing of milk. Milk adulteration is primarily an economic act used to generate extra income. However, the primary reasons for adulteration are the demand and supply gap, the inability to meet urban demand, a lack of milk purchasing capability, the lack of a systematic approach to milk production, and the desire to extend the shelf life of milk.

There have been numerous reports of milk adulteration in the past and the government is now taking care of such issues.

However, the stakeholders are unanimous in their belief that technology solutions can assist in mitigating all of the dairy industry’s challenges. While digitalisation will play a crucial role in making the transformation possible.

Tech interventions are imperative

Digitalisation will have a profound impact on the ‘milk production’ segment in the value chain. In India, dairy farming is unorganised, so technology penetration is relatively less; however, in the last five years, numerous start-ups have mushroomed in this space. These firms aim to increase farmer productivity and reduce wastage.

One of the key areas where digitalisation can have a significant impact is cattle management. Farmers can track cattle feeding patterns and monitor their health by leveraging IoT and advanced analytics. This is likely to boost cattle productivity and milk yield. However, cattle monitoring via AI-based solutions is still in its infancy in India, with only a few companies providing this service.

Prompt Equipments is a pioneer in this field. Over the last 27 years, the company has launched a number of innovative products and solutions that ensure transparency and quality in the milk supply chain. Some of their products include, iSmart milk analyser, milk procurement software, a collection system, chilling solutions, Farm365 management apps etc.

Mehta says, “From the cow to the consumer, milk travels a long way. Prompt’s innovative products and solutions cover the entire spectrum from farm management solutions, milk collection systems and milk testing equipment to ensure that the quality and purity of the milk is retained at every step of its journey.”

Last year, they tied up with IIT Mumbai, to invent a wearable belt ‘BovSmart’. The belt utilises AI and the IoT to monitor cattle breeding and send timely alerts to farmers.

“It’s an animal wearable, which is a comfortable, non-invasive, IoT solution designed for the timely detection of the onset of the cow’s heat cycle. Developed with a specialised algorithm, it is designed to give actionable alerts which ensures timely breeding with a high success rate. The software leads to improved farm productivity and better animal health,” says Shridhar Mehta, Director, Prompt.

Mehta further adds, “Our efforts are focused on combining business intelligence and digital innovation to elevate the global standing of the Indian dairy industry. Dairy farmers are the focal point of our innovations, and we are proud of the fact that we have been able to make a difference in the lives of lakhs of farmers over the last 27 years.”

Stellapps Technologies, another dairytech company, digitalizes and enables supply chain traceability for dairy companies. Their solution, mooOn, is similar to Prompt’s in that it helps to maximize cattle productivity and herd management via a wearable device and app. Through the IoT and sensor based SmartMoo cloud, they have digitised cattle health, milk production, milk procurement, milk testing, and cold chain management.

Stellapps launched MooPay, a direct payment platform for dairy processors and cooperatives, last year. This service makes use of the entire Stellapps product and service portfolio to facilitate instant payment into dairy farmers’ existing bank accounts and assists them in receiving their actual payments without delay. In a recent development, a Bangalore based start-up has signed an agreement with India Post Payments Bank (IPPB) to digitise the dairy milk procurement value chain and promote banking facilities at milk collection centres.

Another start-up in the field is Bodhishop, which is trying to solve the problems of adulteration as well as other issues.

Rajas Paranjpe, its founder says, “Everyone speaks about the adulteration of milk, but nobody is interested to know why this adulteration happens. As a start-up, we decided to take up this challenge and jumped in to find out the root cause of adulteration. After thorough research, we identified that the selling price of milk products, traceability and over-dependence on technology (lab testing, reports etc.) are a few of the main reasons for adulteration.”

To solve this issue, Bodhishop started a tech+human process of verification in 2018.

“We started visiting farms periodically, observed the cows, the process of making milk products, packaging and the basic philosophy of the farmer/seller who was selling these products. In addition to requesting periodic lab reports, we came up with strict parameters (no hormone injections, no formalin, etc) that had to be met when it came to any food product. Farmers just have to keep on making the best products without any adulteration,” he continues.

The physical verification of the farm and the process followed is a major service that Bodhishop as an E-commerce platform provides to its customers. Besides that, Bodhishop also assists sellers or farmers in getting their branded products sold, marketed and shipped across the globe.

Paranjpe tells us, “A few of the major challenges that the farmers approach us with are sales, marketing, branding, packaging and logistics since organic and A2 milk products are expensive. Since such products are free from preservatives and chemicals, they also have a short shelf life. Bodhishop provides 100 per cent support for free warehousing, free marketing, free packaging training and shipping to Gaushalas.”

The start-up offers warehousing facilities to farmers at no extra charge. Once they deliver the products to the warehouse, it takes over from there for the final packaging, selling and logistics.

“We work on getting these products safe for transit and the necessary export compliances at no extra charge. This way, the farmers can continue to focus on production while we get them sales through our platform. We have also introduced all our farmers to the latest technology of packaging glass bottles called as Airpack,” Paranjpe informs us.

Currently Bodhishop has 8 gaushalas listed on their website. While they work with 4 more gaushalas for their Export Incubator Programme and Fodder Drive. They have many more plans for the future, “In the coming year, we wish to introduce more indigenous local products from different geographical locations that will be managed by a separate verification and onboarding team. We are also planning to create free training videos with experts that will teach farmers about how to start organic farming and make the highest quality cruelty-free dairy products that are gaining popularity in India and abroad,” he avers.

Development lies in dairy-tech

The dairy sector in India is still unorganised, but dairy farmers are conscious of the implications of digital transformation and the growth through it. Covid-19 has also established a narrative for them.

That is why, the dairy sector holds immense potential to bring the rural economy back on track. High-end technologies can transform the dairy value chain by unlocking access to relevant insights, products and services at the right time to smallholder farmers. Also, quality and traceability solutions can make India an export hub for dairy and data driven decisions in dairy farming could lead to building a smart dairy value chain.

It’s just that the small farmers, whether rural or urban, require more assistance and guidance to become digital.

“India is still catching up with new technologies. However, there has been tremendous growth through technology in the dairy sector, and with modern technology there is definitely more scope for development in the future,” says Mittal.

Even though the adoption of new technology and digitalisation has been slow in the sector, it is gradually permeating the sector, resulting in its growth. With dairytech start-ups entering the space and bridging the gaps in cattle management and the supply chain, the scenario is changing. The future of the Indian dairy sector appears bright, as digitalization is expected to usher in a new era of growth.

Impact of IoT on smart farming

Today, Internet of Things (IoT) is making a significant impact on milk production. Global milk production to meet the demands of the growing population needs to be enhanced with technology. With this technology, farmers can enhance and improve several dairy related activities such as ascertaining the right time to milk cows, increasing the shelf life of the milk and so on.

In dairy farming, the Internet of Things (IoT) plays a crucial in the monitoring of resources by connecting multiple and heterogeneous objects in mixed dairy farms (which produce milk from cattle and cultivate feed grain for livestock), such as buildings, machinery and vehicles or even living organisms like cattle. The IoT Sensor and Edge Computing (EC) enable resource monitoring and traceability in the value chain, allowing producers to optimize processes, provide the origin of the produce and guarantee its quality to consumers.

IoT technology leverages multiple sensors for collecting various data points and data transmission with low power and bandwidth for communication. Adaption of smart sensors and techniques (data sensing methods like pressure sensing, volumetric sensing, sensing schedules etc.) help to improve resource efficiency, are environment-friendly, enable transparency and data security. These techniques maintain a real-time view of the milk levels, monitor the health of the cattle, warehouse management, and safe transportation access.

IoT platforms and integrated AI engines, gateways, LPWA networks and smart sensors push the industry into a real revolution. The latest technologies are being introduced to automate many of the processes. IoT and data-driven techniques are creating greater opportunities for smart dairy farming. IoT can support farmers with wearable sensor devices to keep them aware of the status of every animal. The sensor-based system can effectively and correctly detect the illness of the cattle before it affects the milk production. IoT serves as an important foundation for cattle breeding by tracking real-time cattle information such as activity, temperature, and pulse. This crucial information can then be used to conduct a thorough analysis to determine cattle oestrus. Increase in milk yield, reduced labor and medicine treatment costs, and increase in the revenue of dairy farms are the most exciting benefits of this technology. This technology has also received close attention from dairy product enterprises and animal breeding initiatives.

IoT and AI based technological methods can be used to minimize the negative factors and enhance those factors that positively affect the production. For instance, an artificial intelligence (AI) model developed based on IoT sensors in milking systems can provide data to help farmers determine when the cattle should be milked or to help the farmer change the feeding pattern. These data can be further enhanced to maintain quality of milk and help to understand production. The state of the art framework by combining IoT sensor, IoT platform and AI solutions should be focused on different aspects of smart dairy farming to assist the farmers increase the milk yield by using different techniques and innovation.

Figure 1: Outlines how IoT can be used for various touch points

The technological adoption of IoT and AI based approach helps in creating innovative methodologies for production (milk yield) and the process of dairy farming. Process innovation can be different for different sets of activities that are performed at several levels in a smart dairy farm. In a dairy farm, the milking process is viewed as a singular process; however, there are several activities that are performed in the farm such as feeding, cow monitoring, and preserving milk. The intervention of IoT can be in different processes and procedures like the feed system to sense the hunger needs of the cows and automatically feed them. It can also proactively monitor automatic heat detection that will assist in reproduction. Assessing health and monitoring cows for disease detection and prevention will help the farmer to locate any animal that needs medical attention.

Smart dairy farming includes real time sensors that collect data from cows with the help of wearable smart collars, machine learning data analysis, and cloud-based data centers that manage data and support the farmer in order to manage quality of dairy products as depicted in Figure 2.

Figure 2: Day to day life of cattle and IoT sensor requirement

Benefits envisaged

IoT and AI technology adoption can play a significant role in the dairy industry to simplify the operations for milk producers and meet the increasing demand for quality dairy products. The technological advancement in IoT can help minimize environmental issues, decrease the use of resources, and enhance animal health by using advanced sensing and data analyzing technologies.

IoT based technology can be used in farm management to reduce costs and make operations efficient. Here are some key outcomes:

Health monitoring: Monitoring and tracking of cattle health data like heart rate and other vital signs of a cow can help farmers in early diagnosis of health issues and provide correct medication.

Monitoring of anomalies in milk production: It is essential to understand cattle behavior and milk production by monitoring continuously and comparing the regular patterns. Each animal can be tagged with a unique identification number to help track the animal’s production and understand their health patterns.

Tracking of automatic water and food supply:

- Water is an important nutrient for all animals, and it is important that cows should have sufficient quality water. Milk contains almost 87% water. The water requirements are closely related to milk production, the moisture content of the feed, and environmental factors such as air temperature and humidity.

- Food is necessary for nutrition because it determines the amount of nutrients available to the animal for health and production. It is important to track the food feeding & and nutrition to maintain good health of the cattle. The underfeeding of nutrients limits production and affects animal health. Overfeeding of nutrients increases feed costs, can lead to excessive nutritional load on the environment, and can be too toxic or dangerous to health.

Technology driven future for the dairy industry

New-age smart techniques using IoT devices will help farmers with increased milk production, advanced monitoring of cattle health & anomaly detection, thereby streamlining the business and processes. Although smart dairy farming using IoT gives various features to a common farmer, it may be a costly affair at the beginning; yet offers the promise of cost recovery with longer usage. IoT helps in efficient monitoring of the feeding and drinking method which can lead to better nutrition of cows, and more milk production. The system with overall architecture, better adaptation of technology, and versatile design can make IoT-based farming more efficient.

Technology Is Transforming Indian Dairy Industry Forever

Here are eight of our favourite tech innovations for beef and dairy farmers.

- CATTLE CARE GOES SKY HIGH

Drones: expensive kids’ toys or transformative business tools? It’s time to accept that drones can revolutionise the way you monitor your herd, checking the location of animals or the state of your fields without even leaving the farmhouse. Drones fitted with cameras and thermal imaging capabilities can monitor livestock movement, perform headcounts and locate stray animals – even at night or in areas of woodland.

There’s more. Drones are useful for monitoring your land too. After all, trudging the fields on a cold winter’s afternoon isn’t always the best use of your time. For example, you can quickly identify any fencing that requires repair, or areas of land that are dry and need watering. You can even use drones as a security device to deter criminal activity. Useful.

- A BOVINE BRUSH TO KEEP COWS COMFORTABLE

Ah, that’s the spot! Millions of cows around the world are getting groomed on demand thanks to the swinging cow brush. The brush begins rotating when a cow makes contact with it – and stops when they walk away. In between it covers all angles of the bovine body to stimulate blood circulation and keep cows comfortable. Okay, it’s not the most earth-shattering, boundary-smashing piece of technology on this list. But your herd will love it.

- AUTOMATICALLY MONTIOR THE CONDITION OF ANIMAL HOUSING

Okay, here’s something truly ground-breaking. It goes without saying that comfortable cows are productive cows. It’s why everything from the air temperature and wind to humidity and water quality has to be just right in your cattle housing. Even slight fluctuations in environmental conditions can cause problems. Now you can monitor the environmental parameters of your cattle housing automatically thanks to an IoT platform patented by Cynomys. Designed specifically for livestock housing, the platform allows you to monitor and adjust more than 20 environmental parameters – such as noise, light and heat – via the cloud. The platform will even identify water leakages and electrical faults in your housing.

But this goes way beyond mere cow comfort. Harmful pollutants can accumulate quickly in cattle housing. For instance, high values of carbon dioxide (CO2), ammonia (NH3) and hydrogen sulphide (H2S) can reduce mucociliary activity, which is the first defence against pathogens. Meanwhile, ammonia has a toxic effect on the mucous membranes that line the cilia and can rupture the pulmonary alveoli – leaving your herd susceptible to bacterial and viral infections. It’s one clever system for monitoring and managing the environmental conditions in your housing – helping to ensure your herd is happy, healthy and productive.

- SLASH LABOUR WITH ROBOTIC MILKING

Collecting the white stuff is the most important aspect of dairy farming. But it isn’t half labour intensive. That, together with the prospect of enhanced milk yields, has got many farmers handing milking duty over to robotic milking systems. No stress, no set milking times and no frenzied rush to the parlour. That alone works to enhance milk production.

Yet while robotic milking systems are becoming commonplace on many farms, the more modern systems do far more than simply collect milk. The latest robotic milking apparatus gather data on health and milk quality that are sent directly to your smartphone. Some systems even perform cell count analysis on every udder quarter at each milking to act as an early warning against mastitis.

- THERMAL IMAGING TECHNOLOGY DETECTS ILLNESS

The use of thermal imaging may sound more at home in a James Bond film than a dairy farm. But it could do wonders for the health of your herd. Inflammation is a key sign of injury and illness in cows – and the thing about inflammation is that it produces heat. By using thermal imaging you can quickly identify these heat spots, making it easy to identify developing health issues before they begin to cause problems for your cows. And because early detection is the key to fast and effective treatment, thermal imaging can be great for your bottom line too. Sounds far-fetched? Many farmers are already using thermal imaging to detect issues such as mastitis, lameness, bluetongue and bumblefoot.

- WEARABLE MONITOR THE HEALTH OF YOUR HERD

Wearable technology such as FitBit has blossomed over the last five years. But humans aren’t the only ones that can benefit. There is now a selection of wearable devices – such as Cowlar and Stellapps – available for cowkind too. All of them designed to monitor cow health, behaviour and performance – whether it’s steps per day, rumination or the amount of food consumed. With all the data sent to the cloud for you to access anytime, anywhere.

But the real benefits for farmers come from being able to monitor health and the oestrus cycle. Imagine, for example, receiving a smartphone or email alert when one of your cows enters heat. Or becomes pregnant. Or develops the early symptoms of a disease or infection. It allows you to take the guesswork out of health and welfare management and act decisively, based on what’s actually happening with your herd.

- OPTIMISE CALF PERFORMANCE WITH COMPUTERISED FEEDING

Mixing milk. Carrying buckets. Day in, day out. Hand rearing calves is labour intensive. So why not let a computerised calf feeder do the job for you? It gives you total control over each calf’s nutritional intake, allowing you to make sure each calf reaches their full growth potential. A computerised feeding system also allows calves to feed on a little-and-often basis, as they would when suckling from their dam. The latest computerised systems will even deliver data on feeding frequency and consumption straight to your smartphone. So you can see your calves are progressing as they should.

- SAVE THE PLANET, ONE COW AT A TIME

There’s a lot of media attention – much of it quite unfair – about cows and their contribution to greenhouse gas emissions. Here to make the world greener, one cow at a time, is Zelp (which stands for the Zero Emissions Livestock Project). This ground-breaking wearable halter automatically oxidises the methane released from the cow’s nostrils – which is where 90-95% of a cow’s methane emissions come from.

The benefit for you as a farmer? Well, as consumers become increasingly eco-conscious, it allows you to vouch for the environmental credentials of your business. You can also potentially seek higher margins through the sale of reduced emissions milk and beef products.

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.

Innovative Technology and Practices Transforming India’s Dairy Farming Sector