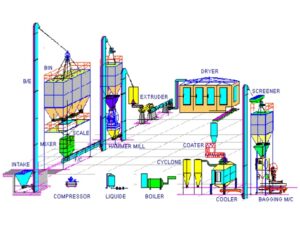

LAYOUT AND OPERATION OF FEED MILL

Vishal Singh, Monika Karnani, Sheela Choudhary and Manju

Department of Animal Nutrition

Post Graduate Institute of Veterinary Education and Research (PGIVER), Jaipur

Feed mill operations -A process and/or a combination of processes used to produce a processed food for fish, animal or human consumption. Feed mill include all the procedures which are helpful to improvement the quality of feed.

These oprations are done for improvement of feed quality, their consumption for animals. After these processes the feed became more digestible, palatable and helpful to increase the production of animal.

- Types of mill: – Feed mill are of three types:

- Large scale feed mill

- Middle scale feed mill

- Small scale feed mil

- Equipments in feed mill:-

Hammer mill: – Hammer mill is used for making various nutrients crumbled. This kind of mill is used in processing oil seeds such as soybean, sunflower, canola, etc. and also for excoriating and milling them out (nutrients with high protein grinded often oil extraction).

Roller mill: -There is usually an immobile roller and other one mobile and the distance between is manual or automatic adjusted. Roller grooves determined (softness) according type of materials and / or the first and the last size of particles. Large grooves are used for large mills and high capacities; and small grooves used for soft particles in lower capacities. For producing very soft product, using rollers with several grooves, sometimes is needed. The type of (RBV Round Bottom Vie) is more applied among various types of roller mill.

- Objectives of feed mill operations:-

- Helpful to increase the productive value of feed.

- Increase the consumption rate of feed.

- After processing the feed become more palatable.

- The digestibility of feed becomes increases.

- Increase the nutritive value of feed.

Operationin feedmill: -In the feed mill operations include all the procedures which are helpful to increase the quality of feed.

- Mixing: – It is done by mixer. Mixers are two types:-

- Horizontal mixer ii. Vertical mixer

- Horizontal mixer:- This mixer has horizontal shaft with number of paddles or ribbon put on this shaft (rotor) by rotation of this shaft and movement of paddles or ribbons, materials in mixer transferred and mixed from one side to another like pendulum.

Kinds of horizontal mixers:

- Paddle mixer

- Ribbon mixers (helix)

In other division, horizontal mixers divided into 2 groups according to number of rotation shaft:

- Single shaft

- Double shaft

It seems that double shaft one is more efficient.

- Vertical mixer: – This mixer has vertical helix which put the middle of main tank of mixer. Materials enter from downward and go upward by this helix often that pour down from the top of mixer (up to geomagnetism) and on the previous materials. This make material circulation and their gradual mixing. Vertical mixer is less capable of producing feed than horizontal ones. Time needed for a homogenous mix, is 5 times more than horizontal mixers.

- Pelletizing: – It is done by feeder. Feeder is a part which is controlled by operator. In different speeds of pelletizing, evacuation speed of feeder should be checked.

- This part effects on pellet quality adjusting pelletizing yolk.

Feeder working included:

- Feed mass maintenance between tank and conditioner.

- Preventing from transferring and direct feed flow from tank to conditioner.

- Producing fixed flow from mash to conditioner.

- Feed adjustments should have done accurately. Adjust machines with various RPM every time in the best conditioner which is done by spiral conveyors with changing speed.

- Steam operation:-

Steam in one of main steps of pelletizing process. Make sure of correct steam flow and high quality adding steam to mash occurred because of several reasons: –

- Increasing starch gelatinization, protein plasticization, binder activation, fiber softening, natural oil releasing, bacteria and mycotoxins control.

- Increasing slippage, increasing capacity and decreasing energy consumption.

- Decreasing erosion in die and roller.

- Decreasing heat from attrition.

- Liquid: – Adding liquids should be according to formulation. If ratio of liquids is not correct, difference that made, effects on pelletizing operation and won’t make pellet quality stable.

- Adding molasses: for correct operation of pellet machine and qualified pellet production, molasses should have added equally and according to formula in feed to be mixed.

- The best way to reach this aim is addition of molasses as tiny particles with high pressure of steam that done in conditioning stage.

- Recommended temperatures included:

- Molasses: 38 to 43 °c

- Fat: 60 to 70 °c (minimum heat domain)

- Hat fat: 82 to 93 °c (the best temperature for penetrating)

- Materials temperature should be between 75 to 85 °c and moisture around 17%. High temperature difference between conditioned materials in mixer output duct and pellets come out from die (around 30 to 60 °c) can show inadequate oil or steam or using thin die. If there are problems about gaining suitable temperature and moisture, it may be because of reasons below:

- Steam quality is not satisfying.

- High humidity of raw materials at the first of operation.

- Cutting blades: –Sometimes blades cause pellets fraction instead of cutting them.There are various designs from very sharp blades or simple breakbars. Blades should usually use for pellets and break bars for cube. If pellet or cube with short cut is considered, blade should be adjusted near to die. A sharp blade is also used for clean and smooth cut.

- Pellet length could be adjusted by changing in feed rate or blades adjustments. Produce pellets with standard length and customer friendly.

- If more than one machine for producing the same feed is operating, adjust blades to produce pellet with equal length. Sometimes there is no need to short blades or any blades.

- Shorter blades are suitable for cutting pellet, which throw pellet directly into evacuation tank for being cold.

- Throw upward blades of pellets opposite of shorter blade keeper and cause a lot of fraction. Sometimes both of 2 blades are also needed.

- Packaging: –

- Filling bags or any other pack, with product.

- Weighing filled bags for reaching to a nearly steady weight.

- Closing bag head or bagging.

- Arrangement on pellet for easier loading of bagged products.

- Labeling final products.

- Transferring to warehouse or somewhere for distribution.

- Label imprint.

- All standard manufactured products must have specs label. This label should have information about feed, maintenance conditions, and usage, and announce needed info about product to customer, totally. This label must be on all bags.

Conclusion: – Feed mill provide us much qualititative feed which is easily digested by animal and poultry bird. Feed is converted in to palatable and nutritious by many procedures in the feed mill. By using the feed mill we can enhance the health and production of animals.