Least –Cost Layer Feed Formulation – How to Formulate Layer Feed in India

Layer feed formulation involves the selection of ingredients and their proportions to create a balanced diet for egg-laying chickens. The dietary needs of layers change as they progress through different life stages, so the formulation must be adjusted regularly to ensure that the hens are getting the right nutrients for optimal health and egg production.

Commercial layer feeds are available but often costly, but home-mixing can be a more cost-effective and cheaper way to provide chickens with a balanced diet.

What is Layer Feed?

Layer feed is a specialized diet for chickens that are laying eggs. It is low in protein and high in calcium to meet the nutritional needs of egg-laying hens. Layer feed should also contain other nutrients that are important for egg production, including vitamins, minerals and essential amino acids.

Layer feed is a specialized diet designed to meet the nutritional needs of egg-laying hens. Layer chickens need high-quality layer feed in order to produce healthy eggs. As earlier mentioned, the formulation of layer feed must be adjusted regularly to ensure that the hens are getting the right nutrients for optimal health and egg production.

A variety of ingredients can be used in a layer feed formulation, including grains, protein supplements, vitamins, and minerals. The proportions of each ingredient must be carefully balanced to create a diet that meets the hens’ nutritional needs.

What are the Ingredients in a Layer Feed?

The ingredients in layer feed vary depending on the specific needs of the chickens. However, some common ingredients include:

- Maize or corn

- Wheat

- Wheat offal or bran

- Rice offal or bran

- Soybean meal

- Groundnut meal

- Bone meal

- Vitamins & Minerals Premix

Layer Feed Stages

Layer hens need different types of feed as they progress through different life stages.

- Chickens in their first 6 weeks of life are called chicks and should be fed chick starter feed.

- Pullets that are 6 to 18 weeks old should be switched to grower feed

- Layers that are more than 18 weeks old and have attained 10% egg production should be given layer feed.

Please note:

- Chicks that are not yet laying eggs should be fed a diet that is higher in protein (18%) and energy (2800 kcal/kg min.) than the diets given to older chickens.

- Laying hens need diets that are lower in energy (2700 kcal/kg min.), protein (16-17% CP) and higher in calcium (3.5-4% Ca) to support egg production.

- Chickens that are not laying eggs should not be given layer feed, as it can lead to problems with bone development and egg production. Instead, they should be fed a diet that is higher in protein and energy, such as a poultry grower feed.

Some important information

- There is 6 or 7 type of feed required in different phases of production for layers in the entire life cycle

- Layer birds consume feed for its energy needs

- All other nutrients are required to adjust according to energy

- The key to successful nutritional management today is through optimizing (maximizing) bodyweight of the pullet.

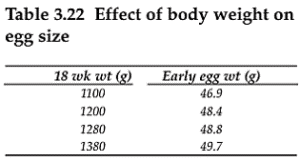

Bodyweight and Egg Size

Pullets that are on-target or slightly above target weight at maturity will inevitably be the best-producing birds for the shell egg market.

But early maturity should be delayed – The traditional concern with early maturity has been too small an egg size.

Summers and Leeson (1983) concluded that body weight is the main factor controlling early egg size

Bodyweight is an important criterion for adequate early production, there is still insufficient evidence regarding optimum body structure and composition.

Nutrients such as protein, methionine and linoleic acid can influence egg size throughout the laying cycle, these nutrients have only moderate effects on early egg size.

Rearing Period Nutrition

Chick Starter 1 & 2 (0 to 9 Weeks)

Starter ration aims to produce a good skeleton, organ development, feathering, skin condition and help to promote an active immune system.

At-6 weeks already 85% of the skeleton has been developed.

This is achieved by feeding the starter feed ad libitum with the correct balance and absolute levels of essential amino acids, energy, vitamins, minerals and a minimum concentration ( 1 .3 per cent) of Linoleic Acid.

Starter 1

| Starter I | |

| Feed to a bodyweight of | 230g |

| Approx age (weeks) | 4 |

| Metabolizable Energy. Kcal/kg | 2860 |

| Crude Protein, % Min | 18 |

| Calcium, % Min | 1.2 |

| Phosphorus (available), % Min | 0.48 |

| Dig. Lysine, % Min | 0.89 |

| Dig. Methionine+Cystine, % Min | 0.67 |

| Dig. Threonine, % Min | 0.59 |

| Sodium, % Min | 0.2 |

| Chloride, % Min – Max | 0.21 – 0.24 |

| Linoleic acid, % Min | 1.2 |

| Choline (Min) Kg/ton | 1.875 |

Normally it is adequate to feed Starter 1 to 4 weeks of age or when the bodyweight is around 230g.

The cumulative feed consumption of Starter 1 feed in this period is about 490g.

This amounts to the consumption of 88g of protein and 1400 Kcal. Of metabolizable energy. Double crumbled 3mm pellets are giving good results

Starter 2

| Starter II | |

| Feed to a bodyweight of | 670g |

| Approx age (weeks) | 5-9 |

| Metabolizable Energy. Kcal/kg | 2800 |

| Crude Protein, % Min | 17 |

| Calcium, % Min | 1.2 |

| Phosphorus (available), % Min | 0.46 |

| Dig. Lysine, % Min | 0.81 |

| Dig. Methionine+Cystine, % Min | 0.63 |

| Dig. Threonine, % Min | 0.54 |

| Sodium, % Min | 0.18 |

| Chloride, % Min – Max | 0.18 – 0.24 |

| Linoleic acid, % Min | 1.2 |

| Choline (Min) Kg/ton | 1.875 |

Starter-2 is 5 per cent less expensive than Starter 1.

Starter-2, feed is to be given up to 9 weeks of age or when the bodyweight of 670g is achieved.

The expected feed consumption of Starter-2, feed is around 1512. This results in the total intake of 257g of protein & 4233Kcal of energy.

Grower / Developer

| Grower / Developer | |

| Feed to a bodyweight of | 1090g |

| Approx age (weeks) | 10-15 |

| Metabolizable Energy. Kcal/kg | 2685 |

| Crude Protein, % Min | 15.7 |

| Calcium, % Min | 1.2 |

| Phosphorus (available), % Min | 0.42 |

| Dig. Lysine, % Min | 0.68 |

| Dig. Methionine+Cystine, % Min | 0.56 |

| Dig. Threonine, % Min | 0.46 |

| Sodium, % Min | 0.18 |

| Chloride, % Min – Max | 0.18 – 0.24 |

| Linoleic acid, % Min | 1.2 |

| Choline (Min) Kg/ton | 1.875 |

This is 8 per cent less expensive than Starter 2. lt also accounts for 44 per cent of rearing feed.

A reduced nutrient density and an increased content of crude fibre (5-6 per cent), during this period, is beneficial.

This diet is to be given up to 15 weeks of age. The requirement is 2303g in this period. This results in the intake of 362 g of protein and 6183 kcal. of energy.

Pre-Lay Ration

| Prelay | |

| Feed to a bodyweight of | Until 0.5% HDP |

| Approx age (weeks) | 16-17 |

| Metabolizable Energy. Kcal/kg | 2680 |

| Crude Protein, % Min | 16 |

| Calcium, % Min | 2.5 |

| Phosphorus (available), % Min | 0.42 |

| Dig. Lysine, % Min | 0.7 |

| Dig. Methionine+Cystine, % Min | 0.57 |

| Dig. Threonine, % Min | 0.48 |

| Sodium, % Min | 0.18 |

| Chloride, % Min – Max | 0.17 – 0.24 |

| Linoleic acid, % Min | 1.2 |

| Choline (Min) Kg/ton | 1.875 |

It is to be given two weeks before the onset of production (about 16 weeks of age).

The prelayer diet has about twice the calcium content of developer ration as well as higher levels of protein and amino acids.

Utilization of pre-lay diets has a strong positive effect on eggshell quality. In two weeks 875g of feed is required, lt results in the intake of 140g of protein and energy of 2345Kcal

Phase 1

| Phase I (0.5% HDP to 40 weeks) | |

| Feed consumption g/d | 110 |

| Approx age (weeks) | 0.5% HDP to 40 week |

| Metabolizable Energy. Kcal/kg | 2550 |

| Crude Protein, % Min | 14 |

| Calcium, % Min | 3.9 |

| Phosphorus (available), % Min | 0.4 |

| Dig. Lysine, % Min | 0.61 |

| Dig. Methionine+Cystine, % Min | 0.55 |

| Dig. Threonine, % Min | 0.48 |

| Sodium, % Min | 0.17 |

| Chloride, % Min – Max | 0.16-0.22 |

| Linoleic acid, % Min | 1.1 |

| Choline (Min) Kg/ton | 1.15 |

Phase-1 feed is to be used from 0.5% production to 40 weeks of age.

In this phase 670mg of lysine is recommended. The ideal amino acid ratios for best performance are specified.

The minimum crude protein recommended in this phase is 15.5%.

Phase 2

| Phase II (Above 41 week) | |

| Feed consumption g/d | 110 |

| Approx age (weeks) | above 41 weeks |

| Metabolizable Energy. Kcal/kg | 2550 |

| Crude Protein, % Min | 13.7 |

| Calcium, % Min | 4 |

| Phosphorus (available), % Min | 0.39 |

| Dig. Lysine, % Min | 0.59 |

| Dig. Methionine+Cystine, % Min | 0.5 |

| Dig. Threonine, % Min | 0.45 |

| Sodium, % Min | 0.17 |

| Chloride, % Min – Max | 0.16-0.22 |

| Linoleic acid, % Min | 1.1 |

| Choline (Min) Kg/ton | 1.15 |

The phase-2 feed is recommended from 41 weeks.

The minimum lysine specified for this phase is 650mg

The Ideal Amino Acid ratios are also specified. The minimum protein recommended for this phase is 15%.

Poultry Feed Historical Background

There is no evidence to suggest that the energy level of diets needs to be changed as the birds progress through a laying cycle

The layer’s peak energy needs are most likely met at around 35 weeks of age when production and daily egg mass output are maximized.

The layer quite precisely adjusts its intake according to needs for energy

to energy is the most important consideration during formulation.

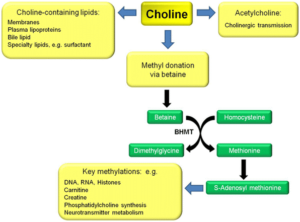

Importance of Choline

Preferably Choline is added directly into the mixer rather than via a vitamin premix because of its hygroscopic nature.

Caution

Change diet at the recommended target bodyweight, the approximate age is a guide only.

Feed the prelay diet two weeks before the onset of egg production, when most pullets show some enlargement and reddening of their combs.

Be prepared to change to the phase 1 diet at no later than 0.5% daily egg production, as the pre-lay diet does not contain sufficient calcium to sustain egg production.

50 % of added calcium carbonate should be 2 mm size in grower and developer diet to develop gizzard.

Max chloride should be 0.24%.

How to formulate feed for BV300 – BV300 Layer Pre Lay Ration

As we know that this ration is given just 2 weeks before laying

Calcium is increased in the diet

Increase calcium in the diet may increase the load on kidneys

Requirements of BV300 for PreLay

Protein – 16%

Energy – 2680 Kcal/Kg

Calcium – 2.5%

Av. Phosphorus – 0.42%

Sodium – 0.18%

Chloride – 0.18%

Methionine – 0.57%

Lysine – 0.7%

Linoleic acid – 1.2%

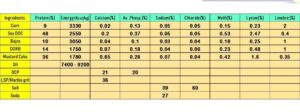

Nutrients present in Ingredients (table)

The first step is the inclusion of protein

We will calculate ingredients inclusion in 1000Kgs

First of all, we left some slack space say; 83kgs in which supplements will be added

We need protein – 16% that means 160Kgs

Now, we include Bajra 20% (i.e. 200Kg), Mustard Cake 5% (i.e. 50Kg) & DORB 7% (70Kg) which contribute 47.8Kg CP and we need 112.2Kgs more

83 + 320(kg) space have been used now 112.2Kg protein is needed from 597Kg ingredients

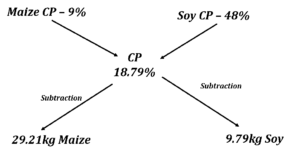

For that, we will use the Pearson method

Pearson Sq. method – To calculate remaining CP

Total ingredients = 597Kgs

Protein 112.2Kgs

Protein% = 112.2X100/597 = 18.79%

Pearson

First step is the inclusion of protein

Now maize & Soy DOC are proportionate for 597kgs

Maize inclusion = 29.21 X 597 / 39 = 447.07kgs

Soy DOC inclusion = 9.79 X 597 /39 = 149.92Kgs

Now protein have been balanced for 16% (160Kgs)

Bajra+Mustard Cake+DORB = 320Kg = 47.8Kg CP

Maize = 447.07kg @9% = 40.2Kg CP

Soy DOC = 149.92Kg @48% = 71.96Kg CP

47.8 + 40.2 + 71.96 = 160Kg CP (16%)

Second step is the Balance of energy (ME)

Energy Protein ratio is imp. Which is 167.5 for starter

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

Energy comes 2692Mcal (which is almost equal to 2680 recommended)

We do not need to add oil, if incase energy is lower than required we must add oil to complete it.

Third step is the Balance of Phosphorus (Av.P)

Av. Phosphorus req is 0.42% or 4.2kg

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

Total Av. Phosphorus comes 1.602Kg è 4.2-1.6 = 2.6Kg is required

To complete phosphorus we need to use DCP, DCP contains 21% Calcium & 20% Phosphorus

>> 2.6/0.2 = 13Kg DCP is required; use PHYTASE cautiously

Fourth step is the Balance of Calcium (Ca)

Calcium required for Prelay ration is 2.5% or 25kg

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

Calcium from feed comes out to be 1.03Kg and from DCP around 2.73Kg so total become 3.76Kg

We need 25Kg Calcium (25-3.56 = 21.24Kg Calcium is needed)

21.24/0.36 = 59Kg LSP is required; 50 % of added calcium carbonate should be 2 mm size

5th & 6th step is the Balance of Sodium (Na) & Chloride (Cl)

Na & Cl req. is 0.18% or 1.8kg/ton

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

| Sodium | 0.089 | 0.029 | 0.06 | 0.035 | 0.028 |

| Chloride | 0.22 | 0.07 | 0.08 | 0.02 | 0.042 |

We need 1.8Kg Sodium (1.8-0.24= 1.55Kg Sodium is needed)

Salt contribute 1.8×0.39 = 0.702Kg Sodium, remaining sodium will be fulfilled by Soda (1.55-0.702=0.848). Required Soda 0.848/0.27=3.14Kg

Seventh step is the Balance of Methionine (DLM)

DLM req. is 0.57% or 5.7kg/ton

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

| Sodium | 0.089 | 0.029 | 0.06 | 0.035 | 0.028 |

| Chloride | 0.22 | 0.07 | 0.08 | 0.02 | 0.042 |

| Meth+Cys | 1.38 | 1.55 | 0.66 | 0.4 | 0.28 |

The requirement is given for methionine + cysteine

We need 5.7Kg Methionine (5.7-4.28= 1.41Kg Methionine is needed)

Requirement is given for Methionine + Cysteine

Cystine is a semi-essential amino acid, synthesized from Methionine.

Methionine is converted in Cysteine on a molecular basis; consequently, 1g of Methionine is converted in 0,8g of Cystine on a weight basis.

Eighth step is the Balance of Lysine (Lys)

LYS req. is 0.7% or 7kg/ton

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

| Sodium | 0.089 | 0.029 | 0.06 | 0.035 | 0.028 |

| Chloride | 0.22 | 0.07 | 0.08 | 0.02 | 0.042 |

| Meth+Cys | 1.38 | 1.55 | 0.66 | 0.4 | 0.28 |

| Lysine | 0.71 | 4.3 | 0.7 | 0.8 | 0.357 |

The requirement is given for 7kg/t

(7-6.87= 0.12Kg Lysine is needed)

Ninth step is the Balance of Choline

Choline req. is 0.1875% or 1.875kg/ton

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

| Sodium | 0.089 | 0.029 | 0.06 | 0.035 | 0.028 |

| Chloride | 0.22 | 0.07 | 0.08 | 0.02 | 0.042 |

| Meth+Cys | 1.38 | 1.55 | 0.66 | 0.4 | 0.28 |

| Lysine | 0.71 | 4.3 | 0.7 | 0.8 | 0.357 |

| Choline Chloride | 0.22 | 0.39 | 0.08 | 0.07 | 0.07 |

(1.875-0.843= 1.03Kg Choline is needed)

Tenth step is the Balance of Linoleic Acid

Linoleic req. is 1.2% or 12kg/ton

| Maize | Soy DOC | Bajra | Must. cake | DORB | |

| INCLUSION (Kgs) | 447.07 | 149.92 | 200 | 50 | 70 |

| Protein % | 40.2 | 71.96 | 20 | 18 | 9.8 |

| Energy (Mcal) | 1488.76 | 382.3 | 610 | 89 | 122.5 |

| Av. Phosphorus | 0.581 | 0.554 | 0.2 | 0.140 | 0.126 |

| Calcium | 0.089 | 0.494 | 0.08 | 0.325 | 0.049 |

| Sodium | 0.089 | 0.029 | 0.06 | 0.035 | 0.028 |

| Chloride | 0.22 | 0.07 | 0.08 | 0.02 | 0.042 |

| Meth+Cys | 1.38 | 1.55 | 0.66 | 0.4 | 0.28 |

| Lysine | 0.71 | 4.3 | 0.7 | 0.8 | 0.357 |

| Choline Chloride | 0.22 | 0.39 | 0.08 | 0.07 | 0.07 |

| Linoleic Acid | 8.94 | 0.6 | 2 | 0.175 | 0.28 |

(12-11.99= Linoleic inclusion is not needed)

Formula

Maize – 447.07Kg

Soy DOC – 149.92Kg

M.cake – 50Kg

Bajra– 200Kg

DORB – 70Kg

DCP – 13Kg

LSP – 59Kg

Salt – 1.8Kg

Soda – 3.15Kg

DLM – 1.41Kg

Lysine – 0.12Kg

Total formula – 995.47Kg

Premix Formula

Threonine – 0.0Kg

Vit. Premix (DSM) – 0.5Kg

Trace Min (Kemtrace) – 0.75Kg

Toxin Binder – 1Kg

IMPETUS Probiotic – 0.2Kg

Enzyme – 0.4Kg

Acidifier – 1Kg

Maduramycin – 0Kg

Choline – 1Kg

Vitamin C Coated – 0Kg

Liver tonic– 0.25Kg

Phytase – 0.1Kg

Grofort – 0Kg

Total – 5.2Kg

Our total formula (995.47 + 5.2) is ready with 1000.67Kg weight

Just like this, you can make feed for other phases

Layer feed formulation is more or less same (minor changes like the inclusion of marble grit and linoleic acid etc)

In the next articles, we try to explain about important ingredients in detail like choline function and inclusion, feed antibiotics, vitamin premixes, mycotoxin binders etc.

Cereal grains

- Maize or corn

- Maize is the principal energy source used in poultry diets in most of the countries because of its high-energy value, palatability, presence of pigments and essential fatty acids.

- It contains highest amount of energy (ME 3350 kcal/kg) among cereal grains.

- It has 8-13% of crude protein.

- It has high TDN of 85-90%.

- Maize has low fibre content and is highly palatable.

- Extremely low in calcium and deficient in vitamin B12 but fair in phosphorus content.

- Yellow maize provides carotene and xanthophylls pigments for colouration of egg yolk, poultry fat and skin when it is used at 30% and above in the diet.

- Maize is an excellent source of linoleic acid which contributes for egg size, and maize protein is mainly deficient in tryptophan and lysine.

- Damaged, immature and improperly stored maize having higher moisture content is prone to aspergillus flavus infestation and produces aflatoxin.

- Supplementation of toxin binders in diet containing damaged maize grain is essential to minimize the risk of mycotoxins problem.

- Organic acids should be added to the maize while storing, if the moisture content in the grain is higher than 16%.

- When the maize is used at >30% in pellet diet, supplementation of pellet binders, molasses, rice bran or oil is required for better quality of pellet.

- Maize can be included upto 70% in poultry ration.

- 2. Sorghum / Jowar

- Sorghum contains slightly lower energy but more protein than maize (ME 3200 kcal/kg; Protein 10%).

- Sorghum protein is deficit in lysine, methionine and arginine.

- Light coloured sorghum varieties can be used as the principal energy source.

- Darker varieties, that are bird resistant, can contain tannins in the seed coat and should be used less.

- Higher levels of tannin in sorghum may reduce the palatability and thereby feed intake. While tannin free sorghum can be used as a sole source of energy in layer diet without affecting egg production, egg weight and energy efficiencies.

- It can be included upto 30% in chicks ration and upto 60% in the grower and layer rations.

- 3.Wheat

- Wheat is rich in protein and calcium and but low in fat and energy compared to maize.

- Wheat is a good source next to maize and sorghum (ME 3100 kcal/kg).

- Its protein content is highly variable (11-14%).

- Wheat protein is deficient in methionine and threonine.

- Wheat contains indigestible non-starch polysaccharides (arabinoxylans) that reduces the performance of poultry.

- The enzyme, xylanase, may be used when wheat is incorporated in feed at high level.

- It can be included upto 20% in chick ration and upto 30% in grower and layer rations.

- Rice/ Rice broken

- The ME content of broken rice ranges from 2400- 3250 kcal/kg.

- Rice is low in protein (7-8%).

- Rice which is unsuitable for human consumption can be used for poultry at low level.

- Rice broken is a byproduct of milling. Its quality is much variable and good quality rice broken can be used in poultry feeds.

- Replacement of maize with rice broken may increase fat deposition in abdominal area.

- It can be included upto 10% in chick ration and upto 20% in grower and layer rations.

- Bajra / pearl millet

- They have 8-12% of crude protein and rich tannin content.

- It can be included upto 30% in chick ration and upto 60% in grower and layer ration.

- Ragi / finger millet

- Ragi contains slightly less protein, fat and more crude fibre.

- The amount of Ca and P are higher in ragi as compared to Maize.

- High crude fibre and tannin content and possibly lower protein quality are the limiting factors in ragi for its utilization in poultry diets.

- It can be included upto 30% in chick ration and upto 60% in grower and layer rations.

Vegetable proteins

- Soya bean meal

- Soya bean meal contains 47-49% protein and is an excellent source of lysine, tryptophan and threonine but it is deficient in methionine.

- The common adulterant includes castor husk and Mahua oil cake.

- Like other oil seeds, raw soybeans have number of toxic and inhibitory substances.

- These toxic, inhibitory substances and other factors in soya bean like saponins can be inactivated by proper heat treatment during processing.

- It can be included up to 35% in chick ration and upto 25% in grower and layer ration.

- Groundnut oil cake/ pea nut meal

- Groundnut oilcake has about 40-47% protein which is very rich in arginine and deficient in cystein, tryptophan, methionine and lysine, but good source of Vitamin B12 and calcium.

- Groundnut oil meal refers to solvent extracted residue and two grades (Grade I & grade II) are available in the market.

- Groundnut oilcake refers to expeller pressed and two varieties (Grade I & grade II) are available in the market.

- The common adulterant includes castor husk and Mahua oil cake.

- Addition of toxin binders and liver tonics is essential in diets containing higher levels of groundnut oil cake.

- Proper processing of the nuts is essential to deactivate the protease inhibitors present in the nuts.

- Groundnut cake can be used upto 35% in chick rations and upto 25% in the grower and layer rations.

Aflatoxin affection

- In rainy season it is specifically labile to contain a toxic factor – Aflatoxins, a secondary metabolite of Aspergillus flavus.

- Mould spoilage and Aflatoxin production can occur at any stage from growing crop to the formulated feed or stored raw material.

- Aflatoxins are the most potent toxic, mutagenic, teratogenic and carcinogenic metabolities produced by the species of Aspergillus flavus and A.parasiticus on food and feed materials.

- Presence of oxygen, conductive temperature (10 – 40ºC) and high humidity favors the mould growth.

- High moisture in the crop, which harvested around wet period and also inadequately dried products, favors the fungal growth and toxin production.

- There are four Aflatoxins, B1, G1, B2 and G2 out of which B1 is most toxic.

- Sunflower oil cake

- The protein quality of sunflower cake is better than groundnut cake may be due to its higher available lysine and methionine content.

- Sunflower oilcake contains 40% of protein.

- It has very short self-life.

- The expeller variety of Sunflower seed meal or cake has high content of polyunsaturated fatty acids.

- It can be included upto 10% in chick ration and upto 20% in grower and layer rations.

- Coconut meal

- It contains 20-26% crude protein with low lysine and histidine content and 2.5-6.5% oil content.

- The higher oil meals tend to get rancid and may cause diarrhoea; hence low oil content meal should be preferred.

- It should be restricted to poultry as it contains low protein and high fibre.

- Linseed meal

- Linseed is rich protein source with low methionine and lysine content and also rich in phosphorus part of which is present as phytate but has only moderate calcium content.

- It is a high source of vitamins like riboflavin, nicotinamide, pantothenic acid and choline.

- It also has protective action against selenium poisoning.

- Linseed oil meal refers to solvent extracted residue and two grades (Grade I; grade II) are available in the market.

- Among the oilseed residues linseed is unique because it readily dispersible in water, forming a viscous slime due the presence of 3-10% of mucilage.

- Cyanogenetic glycoside, linamarin and an associated enzyme, linase in immature linseed hydrolyses it with the evolution of hydrocyanic acid.

- HCN is a potent respiratory inhibitor and hence, depending on the species the minimum lethal dose taken orally has been estimated as 0.5-3.5 mg/kg of body weight.

- Proper water washing, drying and storage can reduce glycosides in the feedstuffs.

- Linseed oilcake refers to expeller pressed and two varities (Grade I; grade II) are available in the market.

- It can be included upto 3% in chick ration and upto 5% in grower and layer ration.

- Mustard cake/ Rape seed meal

- Mustard cake is a fairly good source of crude protein (31-36%), lysine and methionine.

- Its T.D.N value is 74 % and ME is 2,200 kcal/kg.

- It can be included upto 3% in chick ration and upto 5% in grower and layer ration.

- It has rich calcium and phosphorus content of about 0.6% and 0.1% respectively.

- Utilization of mustard cake in poultry diet is not common due to presence of glucosinolates, erucic acid, tannin and higher crude fibre.

- Sesame seed meal / Gingelly oil cake / Til oil cake

- It contains 40% protein, rich in leucine, arginine and methionine but low lysine.

- It was produced from the residues of sesame meal after removal of oil from sesame seed.

- There are three varities – red, black, white.

- White is of high nutritive value than red.

- The ME content in black til cake is higher than that of red variety (1,700 and 1,500 kcal/kg respectively).

- It has high phytic acid and oxalates.

- It can be included upto 10% in chick ration and 15% in grower and layer ration.

- Supplementation of lysine, phytase and Zn will enhance the nutritive value of til cake for poultry.

Animal protein

- Fish meal

- Fish is an excellent source of protein, containing adequate concentrations of limiting amino acids like lysine, methionine and threonine.

- It is also rich in available P, Ca, Se, iodine and vitamin B12.

- Fish meal is the one of the best poultry feed stuffs and a good source of animal protein.

- Its composition varies widely depending upon whether it is made from whole bony fish or fish canary scraps.

- The protein content of fish meal is usually around 60% with a digestibility of 93-95%.

- The presence of fish scales reduces its feeding value.

- It can be included upto 10% in the ration.

- Meat meal

- It is rich in crude protein (50- 55%) and ash (21%) with high calcium about 8% and 4% phosphorus.

- It is low in methionine and tryptophan.

- Good sources of vitamins of B complex, especially riboflavin, choline, nicotinamide and B12.

- Meat and bone meal

- Besides a good source of high quality protein, it is a good source of calcium and phosphorus.

- The carcasses of unproductive and dead animals and offals from slaughter house waste are sterilized and made into meal.

- The quality of meal is variable depending upon the processing methods and the proportion of gelatin it contains.

- The variable quality, contamination and content of phosphorus limit the use of these meals.

- The sterilized meat and bone meal can be included upto 5% in the poultry ration.

Milling by products

- Rice bran

- It is the outer coarse coat of the rice grain separated during processing.

- Rice bran is a valuable product with 12-14% of protein, 13% fibre and 11-18% fat mostly with unsaturated fatty acids and hence it becomes rancid rapidly.

- The oil removed rice bran is available as deoiled rice bran.

- It is a good source of energy (ME 2900 kcal/kg) and B- complex group of vitamins.

- It is high in phytate (1.28%).

- Antioxidants are recommended while storing rice bran.

- Rice bran has a good amino acid profile compared to cereal grains and is slightly deficient in lysine.

- It can be included upto 20% in the chick ration and 30% in the grower and layer ration.

- Wheat bran

- Wheat bran is an excellent food with more fiber content.

- It is laxative when mashed with warm water but tends to counter act scouring when it was given dry.

- It can be included upto 5% in the chick ration and 10% in the grower and layer ration.

- Polishing

- During rice polishing this by products accumulates which contains 10-15% protein, 12% fat and 3-4% crude fiber.

- It is rich in B- complex and good source of energy.

- Due to high fat content rancidity may occur.

- Molasses

- It is a byproduct produced during juice / extract prepared from selected plant material.

- It is a concentrated water solution of sugars, hemicelluloses and minerals.

- Four varities of molasses are commonly available viz. cane molasses, beet molasses, citrus molasses and wood molasses.

- It is palatable, reduces dustiness and improves pelleting.

- Cane molasses is a product of sugar industry and contains 3% protein with 10% ash.

- Beet molasses is a product during production of beet sugar and has higher protein (6%).

- Citrus molasses is bitter in taste with highest protein (14%) and produced when oranges or grapes are processed for juice.

- Wood molasses is a product of paper industry with 2% protein.

- Molasses is a good source of energy and an appetiser.

- It reduces dustiness in ration and is very useful as binder in pellet making.

- It can be included upto 2% in the chick ration and 5% in the grower and layer ration.

- E. Animal and vegetable fat

- Fat (Vegetable/Animal) provides 2.25% more energy than carbohydrate or protein.

- Oil and fat reduces the dustiness in feed and lessens the wear on feed mixing equipments.

- Vegetable oil like corn oil, Groundnut oil, sunflower oil and animal fat like lard, tallow are extensively used in livestock feeding.

- Animal fat contains saturated as well as unsaturated fatty acids of C20, C22, and C24.

- Vegetable fats contain greater proportion of linoleic acid.

- Higher level of poly unsaturated fatty acids leads to rancidity and therefore anti oxidants like Butylated hydroxytoluene (BHT) or Ethoxyquin should be included in high fat diet.

Nutritional requirement of layers and broilers

| Characteristic | Broiler starter feed | Broiler finisher feed | Chick feed | Growing chicken feed | Laying chicken feed | Breeder layer feed |

| Moisture (maximum %) | 11 | 11 | 11 | 11 | 11 | 11 |

| Crude protein (N x 6.25) (maximum %) | 23 | 20 | 20 | 16 | 18 | 18 |

| Crude fibre

(maximum %) |

6 | 6 | 7 | 8 | 8 | 8 |

| Acid-insoluble ash (maximum %) | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Salt (as NaCl) (maximum %) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Calcium (Ca)

(maximum %) |

1.2 | 1.2 | 1.0 | 1.0 | 3.0 | 3.0 |

| Available phosphorus

(minimum %) |

0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Lysine (maximum %) | 1.2 | 1.0 | 0.9 | 0.6 | 0.65 | 0.65 |

| Methionine

(maximum %) |

0.50 | 0.35 | 0.3 | 0.25 | 0.30 | 0.30 |

| Metabolizable energy

(minimum cal/kg) |

2 800 | 2 900 | 2 600 | 2 500 | 2 600 | 2 600 |

| Manganese(mg/kg) | 90 | 90 | 90 | 50 | 55 | 90 |

| Iodine (mg/kg) | 1 | 1 | 1 | 1 | 1 | 1 |

| Iron (mg/kg) | 120 | 120 | 120 | 90 | 75 | 90 |

| Zinc (mg/kg) | 60 | 60 | 60 | 50 | 75 | 100 |

| Copper (mg/kg) | 12 | 12 | 12 | 9 | 9 | 12 |

| Vitamin A (IU/kg) | 6 000 | 6 000 | 6 000 | 6 000 | 8 000 | 8 000 |

| Vitamin D3(IU/kg) | 600 | 600 | 600 | 600 | 1 200 | 1 200 |

| Thiamine(mg/kg) | 5 | 5 | 5 | 3 | 3 | 3 |

| Riboflavin(mg/kg) | 6 | 6 | 6 | 5 | 5 | 8 |

| Pantothenic acid(mg/kg) | 15 | 15 | 15 | 15 | 15 | 15 |

| Nicotinic acid(mg/kg) | 40 | 40 | 40 | 15 | 15 | 15 |

| Biotin (mg/kg) | 0.2 | 0.2 | 0.02 | 0.15 | 0.15 | 0.20 |

| Vitamin B12(mg/kg) | 0.015 | 0.015 | 0.015 | 0.01 | 0.010 | 0.01 |

| Folic acid(mg/kg) | 1.0 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 |

| Choline (mg/kg) | 1 400 | 1 000 | 1 300 | 900 | 800 | 800 |

| Vitamin E(mg/kg) | 15 | 15 | 15 | 10 | 10 | 15 |

| Vitamin K(mg/kg) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Pyridoxine(mg/kg) | 5 | 5 | 5 | 5 | 5 | 8 |

| Linoleic acid(g/100 g) | 1 | 1 | 1 | 1 | 1 | 1 |

| Methionine + cystine (g/100 g) | 0.9 | 0.7 | 0.6 | 0.5 | 0.55 | 0.55 |

| Source: BIS. Poultry feeds – specifications, fourth revision. | ||||||

Formulation for Poultry Feeds as per BIS-2007

Formulation for Poultry Feeds as per BIS-2007

Compiled & Shared by- This paper is a compilation of groupwork provided by the Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request