MANAGEMENT OF COMMERCIAL BROILERS FOR MEAT PRODUCTION

Dr. Rambabu.D, MVSc, Ph.D, MBA.

Associate Professor

Dept. of Poultry Science, College of Veterinary Science, Korutla

PV Narsimha Rao Telangana Veterinary University

Jagtial dist – 505 326. Telangana State.

Introduction

In India, there have been 851.81 million poultry in 2019, a 16.8% rise from the previous Census. In addition, the population of backyard poultry is 317.07 million, up 45.8% from the previous census, while the population of commercial poultry is 534.74 million, up 4.5% from the previous census. However, as human need rises, poultry enterprises are able to provide the demand for high-quality protein, vital vitamins, and minerals. Eggs and meat are readily available for human consumption and are high in protein, fat, and other nutrients. With minimal mortality, broiler chickens grow more quickly, which boosts farm profitability. Every step in the management of broilers is crucial for the broiler industry. Therefore, biosecurity procedures should be performed to reduce the possibility of microbial contamination.

The term “broiler” refers to a bird with an average body weight of 1.5 to 2.0 kg at 7-8 weeks of age, regardless of sex. The broiler’s flexible breast bone and soft flesh are key characteristics.

Squab broilers: Squab broilers are the smallest broilers, measuring 0.9 kg and being 28 days old. These extracts are directly processed, extracted, processed, and marketed as a complete fresh or frozen corpse. Prior to the arrival of the large flock of chickens, the shed, the area, and all the equipment should be thoroughly cleaned and disinfected, 8–10 cm of dry, non–clay waste material, such as sawdust, should be spread, and the hens should be started an hour before the chicks arrive to maintain the proper temperature in the hen house. The chicks should be transported to the farm as soon as possible and fed right away for optimal results.

Shed: To avoid direct sunlight, the chicken shed should face from east to west. One square is the very minimum needed for one adult bird. The home should have a pleasant environment and be rat, cat, and bird proof. Before the daily chicks arrive, the hen house and all of the equipment need to be cleaned and sanitized.

Management of chicks upon arrival

The chicks should be taken out of the box right away. The likelihood of weight loss increases with the amount of time spent in the boxes. Both death and delayed growth will result from this. For the first seven days, provide the chicks with 23 hours of light to aid in their acclimatization and promote self-feeding. As soon as the birds arrive at the farm, start feeding them, and as soon as you can, put vitamins in the water. Set up drinkers and feeders to make it simple for the chicks to acquire food and water.

Rearing day-old chicks

Today’s older chicks should be purchased from a reputable source in the hens’ nesting areas. Healthy broiler chicks should weigh around 33g when chosen. Make sure the aged chickens have enough heat to stay warm. During the first two weeks, avoid abrupt temperature fluctuations in the brooder. Provide sufficient space for the chicks to minimize crowding, which can cause delayed growth. To prevent respiratory infections and encourage the chicks to begin feeding on their own, proper ventilation and lighting are essential. Without further ado, feed the chicks consistently with high-quality food to make greater use of the feed. But don’t let feed tanks sit empty for longer than a couple of hours. A certain schedule should be followed when feeding chicks, especially during the first three weeks. Make sure that there is always access to clean drinking water. Within the first several days, vitamins, minerals, and antibiotics can be added to drinking water. To avoid contamination and parasite infections, keep the brooder dry and clean. Avoid abrupt environmental changes (such as removing the brooder bed and sliding doors) to reduce stress. Before going to bed each night, check the chicks. To maintain proper hygiene, dead birds must be buried or quickly buried.

Management of Brooding

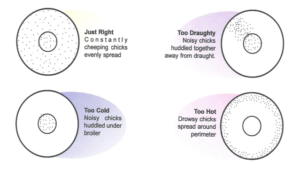

The value of brooding time cannot be overstated. A chick’s first 14 days of existence set the precedent for success. The herd’s final performance will be recognized for additional efforts made during the gestation period. By seven days old, an extra gramme of body weight will result in six grammes of body weight at 35 days old. As growth rates rise, the incubation period will become increasingly crucial. After two hours, have a look at the chicks. Ensure that they are at a comfortable temperature. Chicks who are overheated will attempt to avoid the heat, will pant, will appear calm, and their wings may dip. Chicks who are extremely cold will scurry to the warm, tight-knit groups and scream. At the ideal temperature, chickens will be less flexible and dispersed equally, representing various diets (eating, drinking, resting, and sharing).

Fig. Behaviour of chicks under brooder

The entire house is typically restricted to homes in adverse weather regions. The creation of a space devoid of thermal gradients is the most crucial component of building a whole house. Housing Options In an effort to lower heating expenses, partial house demolition is frequently performed. One can conserve the necessary amount of heat and lower energy bills by minimizing the space offered for discomfort. Furthermore, it’s simple to keep the ideal temperature in a tiny space. Different methods of dividing a house are used by people who divide houses using house-to-house demolition techniques. Curtains are frequently used to divide the house under the roof. To prevent the chicks from being disturbed by draughts, a sturdy 20 cm (8 in) barrier should be set up on the floor in front of the curtain. A central heating source and eye-catching lighting can be used to regulate the partial installation in the same manner that a whole house can be built. Beautiful Lamps When using dazzling type heaters, appealing lights are positioned above the heat source in the centre of the nesting space to draw the chicks in for food and water. The first five days after installation are the optimum for using attraction lights. The five rear lights should gradually be increased during the day to reach the typical lighting of the entire house by the ninth day. The floor’s temperature is crucial for any installed method’s temperature. For the first five days after hatching, chicks are unable to control their body temperature, and thermoregulation does not fully develop until two weeks later. The manager is largely relied upon by the chick to supply the trash with the proper level of heat. When temperatures are too low, infections and unstable growths might develop because the body’s internal temperature drops.

Chicken feet are the best indicator of low heat. One can quickly determine how warm or chilly the chick is by laying the feet on the neck or cheek. Reassemble the litter’s heating and cooling systems if the feet are cold. The chicks ought to be able to fit in the nest if they are warm enough. Ventilation Less air must be taken into consideration in addition to the appropriate temperature. Heat is distributed throughout the house by breathing, and the exhaust maintains a high standard of air quality. because young birds are more vulnerable to air pollution than older birds. Ammonia concentrations should always be kept below 10 ppm. Young birds are particularly vulnerable to frogs. Older daytime birds can experience a considerable wind chill effect at wind speeds as low as 0.5 m/sec (100 ft/min). To minimize downtime, whirling fans should be pointed upward, toward the roof. The feed and water ensure that both suppliers and drinkers are correctly and appropriately stocked in terms of stock amount. Place supporters and drinkers close to one another in a “hot comfort zone.” Metal drinkers should be kept at a height where the lip is level with the rear of the bird. Inspections and changes must be made frequently. In order to stop contaminants from spreading, it needs to be cleaned frequently. On the first day, water should be 0.5 cm (0.20 in) from the drinker’s cup and should gradually recede over the next seven days to 1.25 cm (0.5 in), or the icon’s depth. To prevent spills, every person who consumes iron should be sprayed. Supply of food For at least 10 days after packaging, food should be offered in the form of crumbs and placed on trays, lids, or paper wrapping. Feeders should be made larger over the entire growing season so that the rhinoceros or pan’s mouth can always fit the bird’s back. It is best to set the feed level inside the feed so that it is accessible and the spill is minimized at the same time. To guarantee that the majority of the charge does not occur beyond two weeks of age, chicks should be permitted to clean the feed without utilizing an empty feeder system.

Light

During the flooding phase, the planting area should have at least 20 candles (2 foot candles) of light in a very gloomy location. food and nutrition tests after feeding To determine whether chicks have successfully obtained food and water, plant testing is a useful technique. Pick the chicks at random, and after laying, slightly soften the harvest. The plant need to be gentle and modest. It is a sign that the chicks are not getting enough water if the crops are hard. The chicks don’t eat enough if the plants are swollen and agitated by water. flood control indicator, good or bad The most comprehensive measure of the effectiveness of brooding management is seven-day weights. Broiler performance will suffer if the necessary seven-day weights are not reached. Four to five times the daily weight is lost during the seven-day weight loss programme. The effectiveness of previous management and brooding techniques should be carefully examined if this level of performance is not achieved. Checklist for inspecting poultry During the first week, chickens should be checked on as frequently as possible, and during each visit, the following should be looked at:

- Distribution and behavior of chickens

- Check the temperature of the hens and the crop filling.

- Ammonia air quality levels 10ppm carbon dioxide 0.3% -20 lux in a very dark area of the house. The most typical lighting arrangement for broiler houses with open cases is 24 hours of light during delivery, followed by 23 hours of light and one hour of darkness each day until marketing. In order to train birds to become accustomed to darkness, which can result from an electric shock and require treatment, complete darkness for one hour.

Temperature

Take a thermometer, and set it far from the heat source on a high chick stand. daily temperature records. The ideal temperature range for hens is between 40 and 41 0C. Placing the chicken’s feet on the face or neck is a simple way to check its temperature. If the chicks’ feet are cold, increase the temperature in the brooder. Chicken feet should feel warm. Water: Significant changes in water use should be monitored on a regular basis since they could be signs of sickness, hunger, or water leaks. The first indication of a herd issue is always decreased water intake. For every 100 birds, keep four drinkers, and ensure sure the water is always cool, clear, and accessible. Low water availability will result in a slowdown in growth.

Feeds

For easy access, feed should be laid out on a fresh egg tray, bag, or piece of paper within the first seven days. Introduce the vendors to them gradually. 4 trays should be used for every 100 chicks. This ought to cover half of the farmland. There should be three feeders per 100 birds using conventional feeders. Feed needs to be kept away from mice, rodents, and direct sunlight. Birds shouldn’t be fed liquid or moulded food. To determine whether the birds are being fed well, check the sample of birds 8 hours after arrival and again 24 hours later. Examine a sample of 30 to 40 birds spread out across the hen house. Gently feel the harvest. The crop will be full, soft, and round in well-fed chickens. After eight hours, 80% of the plants should be fully grown; 24 hours later, 95–100% of the plants should be fully grown.

Feeding Program

Starter Feed

During incubation, the chick consumes the egg as food. To receive their nutrition from the processed meal, the chicks must move their bodies during the first few days after hatching. The chicks’ nutritional needs are especially high at this stage due to the extremely limited feed supply. In addition to providing the right nutrition for a healthy diet, hens need also have access to the right natural environments to foster and enhance their hunger. The body’s final performance is highly correlated with its starting development rate (for example, a 7-day weight loss), therefore it’s crucial to make sure the chicks get off to a good start. Starter feeds are usually given for ten days, however they can be given for up to fourteen if specialized equipment is not available. Poorly hatched chicks are more susceptible to illness, weight loss, and environmental stresses. Giving young children the appropriate amounts of nutrients will support healthy early growth and development, ensuring that their weight, goals, and well-being objectives are met. A tiny percentage of the total feed consumed and feed expenses in use are shown by the consumption of feed during the first 10–14 days of chicken life. Therefore, rather than considering individual food expenditures, Starter design decisions should be oriented largely on boosting biological efficiency and total profitability.

Grower Feed

For 14–16 days, broiler grower feed will be provided. Changes in component numbers as well as texture from crumble/mini-pellets to pellets are part of the transition from starter feed to grower feed. The first delivery of the Grower may need to be given as a crumb or mini-pellet depending on the size of the pellet generated in order to prevent any loss in feed intake, for instance if the pellet size is too large for the chicks when the first implant is made. The daily growth rates of broilers keep increasing quickly at this time. A balanced diet should be the foundation for this stage of growth. The availability of an abundance of healthy nutrients, notably energy and amino acids, is crucial for achieving optimum biological functioning. To avoid any food shortages or growth, the transition from starter to grower feed should be handled carefully.

Finisher Feed

After 25 days, finisher feeds are typically administered. Broilers grown up to more than 42 days will require additional Finisher feeds in order to turn a significant profit. Depending on the age you choose and the amount of processing and production capacity, you must decide how much broiler Finisher supply to buy. The majority of the costs associated with feeding and broiler feed go into feeds for finishers.

In order to maximize the financial return of the product being produced, the Finisher supply should be planned.

Starter Grower Finisher

Energy (MJ/kg)* 12.65 13.20 13.40

Crude Protein (%) 22-25 21 – 23 19 -23

Male and female broilers are fed separately

By using different nutritional plans for each sex, male and female broilers that are bred separately may have the chance to boost their profitability. The most popular approach is to use the identical feeds for both sexes, but to give women less time for their Grower and Finisher meals. To maintain optimal growth in advance, it is strongly advised that the quantity or timing of Starter supply be kept constant for both men and women.

Advantages of pellets vs mash

To raise the bird on a daily basis, you need 3.5 kg of pellets. To care for the bird on a daily basis, you need 7-8 kg. There are no feed errors. The pellet continues to be consumed even after it hits the ground. A feed spoiler is present. The mush crashes to the ground, mixes with the trash, and then collapses. For five weeks, birds are sold at the same weight. Different birds sell in 7-8 weeks. Every nutrient required by a chicken is contained in a single pellet. This clarifies why all of the birds are sold at once and at the same weight. Due to the uneven spacing of the mash, each bird does not consume all the nutrients it requires.

housing plans Broilers can be kept in cages or sharp waste (deep litter) or wire on the floor. Due to issues including breast lumps, weak legs, and significant initial investment, broiler farming with a cage, slats, and fence is less common than broiler farming on the ground.

Rearing methods

To incubate and raise broilers, it can relate to one group at a time (all in the middle of a programme) or numerous groups.

All-in all-out system

The farm will only have one batch of broilers at any given time that are in the same leak under the all-in all-out system. This approach is more hygienic, has less sub-clinical infections and horizontal disease transmission, which results in a lower mortality rate, better growth rates, and increased feed efficiency. Enough chicks will be purchased to accommodate all the farms, raised, and sold in one location. However, this approach necessitates a high and stable cost per bird, making it unsuitable for large-scale farming.

Multiple batch system

The multi-batch approach involves growing many chicks at once for a period of one to four weeks. Here, the farmer purchases day-old chicks every week, every two weeks, once every three weeks, or once a month, and sells adult broilers. Chicks are grown until they reach their ideal weight, which is usually between five and six weeks old. The best programme in India currently has a weekly gap between collections and “direct marketing” and 5 to 6 sets of broilers available at any given time. Depending on their body weight, the birds will be sold here every day between the ages of 40 and 54. This will give the weaker animals a chance to grow compensated while allowing the heavier birds to be sold earlier.

Floor space, feeder space and waterer space

Broilers’ need for floor space varies based on factors including marketing age, housing systems, body weight at the time of marketing, and ambient temperature. The location of the feeder and waterer also vary based on the temperature of the surrounding area and the health of the birds. The approximate floor, feeder, and waterer area requirements for broilers are as follows. The table shows how much floor, feeder, and water area is needed for each type of bird.

| Age | Floor space / bird | Feeder space / bird | Waterer space / bird |

| Up to 18 day | 450 cm2 | 3 cm | 1.5 cm |

| From 19 days to 42 days | 1000 cm2 | 6- 7 cm | 3 cm |

Broiler cage-rearing

Broilers can be raised in cages as well. Grower cages and broiler cages are similar. The underside of the cage might have some plastic coating to stop breast blisters. The amount of floor area needed in cages is half that of deep-litter cages. The following are the relative benefits and drawbacks of broiler cage rearing:

Benefits

No money is spent on waste, there are no occurrences of coccidiosis, there is less cannibalism, cleaning and sanitizing are simple, and the market’s quick bird catching minimizes damage. improved growth and feed effectiveness.

Limitations

- Frequent twisted keels

Bones The wing’s bones will be more fragile, which will present a challenge for that processor. The unidentified growing item in the rubbish disposal system is inaccessible to birds.

- Staff-friendly cleaning trays for files.

- Investment Cages require a substantial upfront investment.

- Birds won’t be at ease, especially in the summer.

Broiler rearing with gender segregation

Male and female broilers have different nutritional needs, growth rates, and low locations. Male broilers require more space and nutrition than female ones because they grow more quickly. These factors lead to the daily separation of male and female broiler chicks in several nations. Instead of “for sex,” like in the case of egg-laying chicks, broiler chicks are supplied sex here “in the shape of feathers for sex.” Sex broiler brood chicks reproduce and are raised in separate pens until sold. Both men and women are given different foods. While female broilers require less energy and less protein, males do.

Benefits include

- Special market demands can be satisfied while maintaining the same weight of livestock. Male corpses will only be used for deboning and other cutting components; females can be raised, dressed, and sold whole.

- It will be feasible to feed people more precisely to fulfill their individual needs. Better growth and feed efficiency will result from this.

- The automatic processing equipment may be modified for increased precision, efficiency, and reduced waste because the herd is comparable.

Why Less cannibalism and disarray because to the herd’s increased resemblance.

Limitations

- Costs • To meet the requirement for both male and female progeny, large breeding herds are necessary, which comes at additional sexual expenses. On the other hand, hens that produce young may demand that their consumers consistently purchase an equal number of male and female chicks.

Quality of Litter

Replace any waste that is dusty, damp, or old with brand-new, high-quality garbage. Litter should only be disposed of where the chicks will be housed in the first week and other areas where litter is disposed of in areas where it may not be possible to replace litter after each broiler cycle due to the cost of new litter, the availability of new waste, or the difficulty of disposing of used waste. Newspapers may be placed in the incubator for the first 24 hours if littering is not an option. As soon as possible, before the immune system has had time to mature and the yolk stalk has had a chance to cool, high levels of pollutants should be avoided coming into contact with chicks. A newly hatched chick’s capacity to endure and flourish in its new habitat can be impacted by factors like as the type of dirt, temperature, texture, and humidity. When in touch with litter, chicks can lose a large portion of their body heat through the skin on their legs. As a result, a bed that has not been adequately heated before the eggs are set can significantly lower the chance of the chicks surviving. It is advised that you warm the incubator for at least 24 hours before the chicks arrive in chilly climates to make sure the temperature of the garbage is also warm. A thermometer can be used to check the temperature of the litter, or you can just feel your skin to see how hot the chicken leg is.

Anti-Coccidial Initiative In general, using anti-Coccidials has positive health effects. These products frequently maintain waste and strengthen intestinal integrity. To maintain a healthy litter status when using a live vaccination to treat coccidiosis in broilers, intensive care and intestinal health care are necessary.

Withdrawal Period

When utilizing controlled drug supplements, a discharge may be necessary according to local regulations. The primary goal of employing withdrawal feed is to give meat products enough time to age before processing to completely eliminate the possibility of pharmaceutical residues. To ascertain the necessary release time, manufacturers are urged to reference local laws. A reduction in nutrient-dense diets is not advised during withdrawal to sustain bird growth and wellbeing.

Vaccination

| S.No. | Age | Vaccine | Route of administration |

| 1. | First day | Marek’s (at hatchery) | S/C at neck |

| 2. | 5-7th day | RDV F1 | I/O or I/N |

| 3. | 14th day | IBD Vaccine | I/O or I/N |

| 4. | 21st day | RDV La Sota | Drinking water |

| 5. | 28th day | IBD Vaccine (Booster) | Drinking water |

Performance Indices for efficient operation of broilers

- Livability% = Number of birds sold x 100 / Number of birds initially

Average value is 97 to 98%. - Feed performance or feed conversion ratio FCR = Total total feed consumed per kg in Kg / Means weight gain in Kg.

A value of about 1.8 or less at six weeks is the best. - Broiler Performance Efficiency Factor (BPEF): BPEF = Live weight in kg x 100 / Feeding efficiency.

The higher the price values the better. A value of 100 or more is attractive. - Broiler Farm Economy Index (BFEI) BFEI

= Medium live weight (kg) x percent / feed efficiency x growing time (days)

A BFEI value of 2.0 and above indicates better farm management and efficiency of birds; and a value below 1.3 indicates poor performance of the herd.