Management Of Hatching Eggs for Successful Hatchery Operations in India

BY-DR AK KAUSHAL,POULTRY CONSULTANT, BARWALA

Poultry farming has become one the most important aspects of agriculture. Poultry production is an important and diverse component since egg and meat are part of health and diet for larger population all over the world. Poultry production is generally considered as supplementary to other livelihood activities, but poultry is actually a form of saving and insurance, and contributes to income diversification. For better production management of hatching eggs is very important. Following points are consider during hatching egg management:-

Clean hatching eggs

Very dirty eggs should not be used for hatching. If they must be used, they should be dry-cleaned when gathered. The cleaner the shell surface, the less likelihood there will be bacterial contamination and shell penetration. The most important consideration in hatching egg sanitation is to manage the flock so that eggs are clean when gathered. Many factors enter into accomplishing this goal. Sloping wire-bottom rollaway nests, with or without automatic collecting devices, generally result in clean eggs and a minimum of bacterial contamination. Clean eggs can also be produced in conventional box-type nests if nesting material is diligently kept clean by continually replacing soiled material. Egg breakage can be reduced by providing sufficient nests for the peak laying period. The number of floor and yard eggs can be reduced by proper design and location of nests when maturing pullets need them; location and design will vary with the type of house. Nests should be darkened and ventilated, and hens must be prevented from roosting in them at night, because they contaminate the area with fecal deposits. Keeping the litter dry is an aid in preventing soiled nests and nest material. Proper design and construction of the breeder house to create conditions conducive to keeping litter dry aids disease control at the hatching-egg level. Table-egg breeding stock perform satisfactorily in litterless housing either all slat or sloping wire-floor houses and this largely eliminates dirty eggs resulting from tracking litter and feces into the nests. Heavy breeds and turkeys do not perform as well on these floors, so combinations of part slat and part litter are used to aid in litter management. Measures should be taken to prevent Salmonella infections by using Salmonella-free feed ingredients, particularly meat meal, eliminating these pathogens from mixed feed (pelleting), keeping feed clean by good feeding practices and storage facilities, and keeping natural carriers (rodents, wild birds, pets) out of pens and houses. Preventing salmonellosis and other types of enteric infections also helps prevent wet droppings, which contribute to wet litter. Above all, eggs should be gathered frequently, especially in the early part of the day when most hens visit the nests. They should be gathered in clean, dry equipment and held in a dry, dust-free area.

Sanitization of eggs

The shell surface of hatching eggs should be disinfected immediately after gathering. If sanitization or fumigation cannot be done on the farm, it should be done as soon as possible thereafter, preferably before eggs enter the hatchery building or at the entrance to the egg-processing area. The more delayed the sanitization, the less effective it is because the bacteria will have had longer to penetrate the shell. Unsanitized eggs raise the possibility of carrying a serious infection into the hatchery where susceptible newly hatched chicks are present. Because of possible adverse health considerations resulting from the inhalation of formaldehyde fumes, farm and hatchery personnel should be alert for any new and effective shell sterilization compounds and methods that may become available.

Washing and liquid sterilization

Washing eggs with warm detergent solution at a temperature (43-51.8°C) always higher than that of the eggs entering the washing machine at least 16.6°C higher but not to exceed 54°C followed by sanitizing the shells with a chlorine compound, quaternary ammonia product, or other sanitizing agent is routine for commercial eggs. The procedure has been employed successfully with hatching eggs, but some real disasters have occurred where thousands of eggs were contaminated rather than sanitized when dirty water was used, especially in recirculating washing machines. Even if eggs are washed properly, very dirty eggs should be cleaned first by sanding to prevent excessive pollution of the washing solution and equipment. If the iron content of the wash water exceeds 5 ppm, it favors multiplication of certain types of bacteria and creates a serious egg spoilage problem. If egg washing is done, it should be only with a type of machine (brush conveyor type using flow-through wash water principle) that will ensure against contamination with dirty wash or rinse water. Very careful supervision is also necessary to see that all equipment is working properly at all times and is cleaned daily. In some types of machines, if the washing system fails, a few eggs can contaminate the water and, thus, contaminate thousands of others before the problem is detected and corrected. Contaminated eggs in the incubator set off a chain reaction of egg explosions that contaminate surrounding eggs, causing more “exploders” and more contamination. While washing and liquid sterilization of hatching eggs can be done satisfactorily, the procedure is subject to operational difficulties and should not be attempted without full knowledge of the hazards involved. Whenever cold eggs are moved into a warm, humid atmosphere, moisture condenses on the cold shells (called “sweating”). This moisture provides a medium for the growth of bacteria and fungi already present on dirty or unsanitized shells or originates in contaminated warm air around the eggs. Cold eggs should, therefore, be warmed to room temperature in clean, low humidity air before placing them in an incubator.

Storage facilities

After fumigation or other shell sterilization, hatching eggs are frequently stored in a cool room (about 10°C) at the hatchery until set. Cool rooms should be clean and free of mold and bacteria and periodically disinfected to prevent recontamination of shells. Holding hatching eggs too long or under improper storage temperature, humidity, and environment can result in poor quality chicks. Clinical histories indicate that infection in young chicks may sometimes be traceable to fungus-contaminated hatching eggs; infections have been produced experimentally by contaminating shells with fungus spores. In normal hatchery operations, eggs cannot be set immediately after they are laid. Many hatcheries set eggs once or twice in a week. If hatching eggs are stored up to 1 week, hatching eggs should be kept in an egg holding room with the temperature of 65oF and the relative humidity of 75%. When storing eggs less than 10 days, store them with the large end up. If eggs are held for 10 days or more, hatchability will be improved if stored with small end up.

Handling of Hatching Eggs and Storage

The quality of hatching egg cannot be improved after lay but one can reduce the loss in hatching egg quality by adopting some standard procedures.

Maintaining egg quality in the breeder house

The hen will lay her eggs over nesting material. Use of enough clean, dry and mold-free nesting material can avoid cracked and dirty eggs. Similarly hens to be trained to use nests to lay eggs instead of laying on floors by providing sufficient number of nest boxes well in advance before the laying starts.

The frequency of hatching egg collection is very important to maintain quality. Hatching eggs should be collected at least 4 times a day. Hatching eggs are susceptible to contamination and every effort must be made to reduce the microbial load. Therefore, it is imperative that people wash and sanitize their hands before collecting eggs from the nests or egg belts. The flats that eggs are placed on must also be sanitized and free of organic material.

Selection of hatching eggs

Not all eggs laid by a breeding flock are set. Eggs that are cracked, dirty or misshapen are usually not used for hatching. Very small or very large eggs do not hatch as well as eggs in the middle size range. Eggs with thin or very porous shells are not likely to hatch well because of excessive losses of water during incubation.

Reducing contamination of hatching eggs

Poor hatching egg sanitation can be a major cause of lower hatchability and poor chick quality. There is no such thing as a sterile eggshell. More bacteria are picked up on the shell when the egg passes through the cloaca where urine and intestinal contents also pass. The bacterial load found on an eggshell at the time of lay ranges from 300 to 500 organisms. After oviposition, every surface the egg comes in contact with can further inoculate the shell surface. After an egg is laid it begins to cool. During the cooling process the egg contents begin to shrink and producing negative pressure. This is one of the more opportune times for bacteria on the shell surface to penetrate the eggshell.

Egg has many natural defense mechanisms to reduce bacterial penetration. The shell itself provides some protection. The cuticle on the surface of the eggshell is the best natural barrier to penetration. The inner and outer shell membranes provide additional barriers. The albumen provides a somewhat effective control over contamination. The albumen has a high pH in which most bacteria cannot survive. The chalazae contain an enzyme, lysozyme, which has antibacterial properties.

Many breeder people choose some methods to reduce the microbial load over the eggshell. Sanding, buffing, and wiping the hatching eggs are not good methods of sanitation. Sanding and buffing will remove at least part of the cuticle resulting in eggs that are more susceptible to penetration. Fumigation with formaldehyde gas is an effective method of sanitizing hatching eggs. Solutions containing quaternary ammonium compounds, formalin, hydrogen peroxide or phenols may be moderately effective in reducing the microbial load over hatching eggs. DO NOT wash eggs unless necessary. If it is necessary to wash eggs always use a damp cloth with water warmer than the egg. This causes the egg to sweat the dirt out of the pores. Never use water cooler than the egg. Also, do not soak the eggs in water.

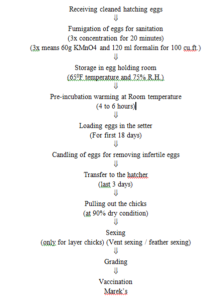

Hatchery operation

The operation of a chick hatchery involves the production of the largest number of quality chicks possible from the hatching eggs received at the hatchery. In addition, chicks must be produced economically. The sequences of hatchery operations followed in commercial hatcheries are

Advantages

- Securing hatching eggs

- Traying hatching eggs

- Fumigation

- Cold Storage

- Warm eggs prior to setting

- Loading of eggs

- Candling

- Transfer of eggs

- Pulling the hatch

- Hardening

- Grading

- Sexing

- Vaccination

- Chick delivery

- Washing and cleaning

- Disposal of waste

1) Securing hatching eggs

Hatcheries can get the hatching eggs from any one of the following ways:

- From own breeder flock

- From other breeder flocks

- From other hatcheries

2) Traying hatch eggs

The eggs from the breeder flocks should be transferred to the egg setter trays in the hatchery immediately after receiving.

3) Fumigation of hatching eggs

After traying, eggs are to be kept in the fumigation chamber for fumigation. Fumigating with 3x concentration of formaldehyde for 20 minutes will kill about 97.5 to 99.5% of the organisms on the shells. One ‘x’ concentration means 20 g of KMnO4 with 40 ml of formalin for 100 cubic feet (3x means 60 g of KmnO4 + 120 ml of formalin for 100 cubic feet).

4) Cold Storage

When the eggs are not set immediately after receiving, they should be kept in cold rook at the temperature of 65 oF and 75% relative humidity.

5) Warm eggs prior to setting

Approximately 6 hours prior to placing eggs in the setter they should be moved from the egg-cooler room to normal room temperature. Here, atmospheric air condenses over eggshell and form water droplets over eggshell, which is called as ‘Sweating’. It is advantageous to warm eggs before placing them in the incubator by avoiding creation of low temperature in the machine by placing cool eggs directly.

6) Loading of eggs

Placing of eggs in the setter is called ‘Loading of eggs’. Eggs can be set in the setter either all-in all-out basis or batch basis. Most of the commercial hatcheries are practicing batch system of loading eggs in the setter that will minimize the initial time taken to reach normal incubation temperature in the setter. In this case, each setter is having hatching eggs with different stages of embryonic developments.

7) Candling

Candling is a process in which eggs are kept in front of a light source to find out the defects in eggshell, embryonic development etc. Candling can be done as early as five days of incubation, but errors in candling often occur at this time. Under commercial operations, candling is done when the eggs are transferred from setter to hatcher (at 19th day for chicken eggs). There are two methods of candling that can be used. The fastest method involves the use of a table or mass candler. An entire tray of hatching eggs may be placed on the mass candler and examined with one observation. Candling with a spot candler or individual candler is a little slower, but it is more accurate.

8) Transfer of eggs

In modern incubators, eggs are transferred from setter to hatcher at 19th day of incubation (for chicken egg) or when approximately 1% of the eggs are slightly pipped. In general, one-seventh of total incubation period is needed to keep eggs in the hatcher.

9) Pulling the hatch

The process of removing the chicks from the hatcher is often called pulling the hatch. Chicks should be removed from the hatcher as soon as all are hatched and about 95% are dry. Excessive drying in the hatcher should be avoided.

10) Hardening the chicks

When the chicks are first placed in the chick boxes they are soft in the abdomen, are not completely fluffed out, and do not stand well. They must be “hardened” by leaving them in the boxes for 4 or 5 hours. Such hardening makes it easier to grade the chicks for quality, and the chicks are more easily vent-sexed.

11) Grading the chicks

No chick below the minimum standard must be allowed to go to a customer. Some standards for quality are, 1) No chick deformities 2) No unhealed navels 3) Above a minimum weight 4) Not dehydrated and 5) Stand up well.

12) Sexing the chicks

Layer type day-old chicks are need to be sex separated either by vent sexing or auto-sexing (feather sexing). In case of meat-type day-old chicks sexing is not practiced.

13) Vaccination

Most chicks are vaccinated against Marek’s disease in hatchery before delivery. Most common method of vaccination of day-old chicks is by subcutaneous method in the nape of the neck.

14) Chick delivery

Baby chicks should reach the customer’s farm early in the morning. Not only the weather is cooler during this part of the day but the early arrival allows a full day for close observation of the chicks by the caretaker.

15) Washing and cleaning

Cleaning the hatchery between hatches is of primary importance. The process must be complete. Except for the setters and setter room, every piece of equipment must be thoroughly vacuumed, scrubbed, disinfected and fumigated.

16) Disposal of waste

Hatchery wastes include infertile and non-hatched eggs, and dead and cull chicks that should be disposed in such a manner not to create problem to the neighbors and also not to contaminate the hatchery premises.

Steps Involved In Commercial Hatchery Operations