LATEST APPROACH TO POULTRY WASTE MANAGEMENT PRACTICES IN INDIA

Poultry waste is one of the major pollutants if not properly disposed. Poultry feathers can be treated chemically or biologically with microbes to improve the nutritive value of feather wastes which can be used as animal feed. They can also be biologically converted into feed supplements, biodiesel, and biodegradable plastic and organic fertilizer. The offals are utilized by various methods like rendering, incineration, burial, controlled land filling, composting and anaerobic digestion. Rendering produces meat-bone meal which may be used as animal feed or fertilizer. Composting reduces pathogens. The compost is used as soil conditioner or fertilizer. Poultry litter contains carbon, nitrogen, phosphorous, chlorine, calcium, magnesium, and sodium, manganese, ferrous, copper and arsenic. It is used as a very good source of fertilizer. Methane gas produced from poultry litter is converted into electricity using a patented technology. Altogether, poultry wastes can be effectively utilized if properly treated to reduce the ill effects and a range of value added products like fertilizer, biodiesel, animal feed, electricity, bone meal and biodegradable plastic can be produced.

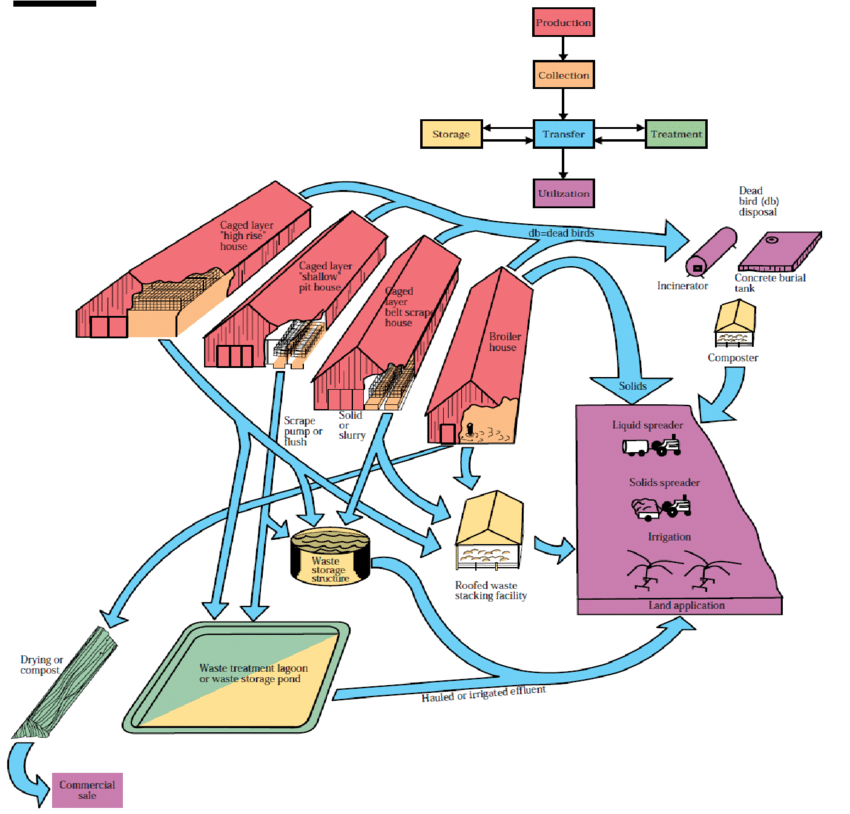

Poultry is one of the fastest growing segments of the agricultural sector in India today. As crop production alone may not solve the food availability of the fast growing population of country. The poultry production has been the appropriate answer for fulfillment of requirements of balanced diet. India is now the world’s third largest egg producer, fourth largest producer of chicken and fifth in poultry meat production. In India Poultry meat, contributes 47.05 percent of total Meat production. As poultry industry expanding its wings, it’s also increasing the challenges to properly manage the waste produced from it. It was stated that if waste must be transported to a disposal site, it must be placed in sealed containers to prevent spillage . Globally, an excess of 90% poultry waste is spread on land close to the poultry farms . The poultry industry produces large amounts of solid waste like bedding material, excreta, feed, feathers, hatchery waste, mortality waste and waste water like faeces, urine, saw dust, remnants of drugs pesticides, disinfection of chicken houses and abattoirs. Poultry manure contains high phosphorus which has positive effect on the growth and productivity of crops.

It is also effective when combined with mineral phosphorus fertilizer for farm use. The poultry wastes also pose serious environmental pollution problems through offensive odours and promotion of fly and rodent breeding .Therefore appropriate dispose/management of waste is required for minimizing the risk and fetching the better vantage of poultry industry. There are different techniques of management and disposal of poultry waste, to reutilize the nutritions and avoid the risk. In this review different methods have included to emphasize management and disposal of poultry waste.

In general, for each kg of feed consumed, a chicken approximately produces 1 kg of fresh manure with variable water content, while a commercial layer produces about 20 kg waste per year .Waste of a poultry farm includes litters from broiler and layers, hatchery debris, dead birds and much other debris. Broiler litter is a mixture of manure, bedding material, wasted feed, feathers and in some cases soil . While on the other hand, litter from cased layer includes all above-mentioned items except bedding and casing material. These waste can be used successfully for crop production, but require soil testing, crop nutrient requirement, nutrient value of manures and proper storage and application. Moreover poultry litter can also be used as feed ingredient for cattle and as fuel in powerhouse . However, waste management mostly driven by environmental safety regulation of a country, concerns of people and profitability.

Growing concentration of egg production unit’s results in the production of poultry waste on a large scale. This also poses problems of handling and disposal for many poultry producers, with the public becoming more aware and concerned about environmental pollution. Two main types of wastes are produced by poultry enterprises depending on the rearing system adopted on the farm: poultry litter and cage layer waste. Poultry litter is the waste from deep litter systems and does not have much nutritive value, since it contains mostly used litter material. Cage layer waste consists mainly of excreta collected under the cages, spilled feed and feathers. Cage rearing of layers is the most widely followed system for layers.

Management of manure and Litter —————

Roeper et al., (2005) stated that a major problem coming along with the poultry production is the manure that needs to be taken care of, avoidance of proper treatment can become risky for environment and humans. Generally, manure refers to faeces and urine produced by animals; it contains organic matter and nutrients, which improve its fertilizer value. Litter is a waste by-product of poultry industry, which consists of feces, bedding materials, wasted feed, and feathers (Chen Z et al., 2014). Dong and Tollner (2003) stated that poultry manure can cause environment related problems such as water, air and land pollution. Ammonia, dimethylamine (DMA), trimethylamine (TMA) are the common odorous compounds from poultry manure, (Nowak et al., 2017) study of genotoxic and cytotoxic activity of these compound in the model chicken cell line (LMH), suggested that these compounds can induce cell death by necrosis and apoptosis. The risk of nutrients, organic material, and pathogens contaminating water bodies and public water supplies will greatly increase if manure is spread adjacent to streams, waterways, and lakes . High nitrogen content in the poultry manure gives rise to the problem of nitrate leaching and contamination of ground water which in turn effects sources of drinking water with subsequent impact on the health of human beings particularly children.

Soil amendment

Application of poultry manure improve water holding capacity of soil and increase lateral water movement, therefore improving irrigation potentiality and decreasing the dryness of soils. It increases the number and diversity of soil microorganisms, particularly in sandy conditions. It is difficult to prescribe any uniform standard but care has to be taken to spread poultry manure thinly on the soil instead of dumping in a heap. Since soil condition also varies widely it is difficult to prescribe any limit. It was evidenced that continuous application of composted and noncomposted poultry manures causes the improvement of physical properties of degraded soil, and subsequently increased the maize grain yields more than the application of poultry biochar and unamended manure.

As fertilizer ————

The proper handling and management of manure can augment or replace purchased commercial fertilizers . Utilization of poultry waste as a source of manure for crop production has been the favored system for recycling nutrients. The approximated percentages of nutrient intake excreted by poultry are nitrogen (65.5%), potassium (83.5%) and phosphorus (68.5%), it is beneficial increased crop production . Other elements such as calcium, magnesium, sulfur, boron, molybdenum, cobalt, copper, iron, manganese and zinc which are deficient in commercial fertilizer are also there in poultry manure in appreciable amounts. The manure is stored in most of the farms before disposal, at least for a period of one month and this leads to loss of nearly 40% N which reduces the value of the manure. In one study chicken manure was added for sweet potato culture and it was suggested that small-scale farmers should avoid use of high levels of chicken manure because higher levels of manure would increase vegetative growth at the expense of tuber formation

Livestock feeding ————

Poultry litter has been used in diets for poultry, lambs, ewes, swine, lactating cows, wintering cattle and brood cows. Poultry litter/manure is used as livestock feed in other countries also including Israel and some states in the US (Smith and Wheeler, 1979). Drying of poultry manure is perhaps the oldest procedure of processing waste for refeeding. It was stated that amino acid nitrogen of cage layer waste ranges from 37 to 40% of total nitrogen and that about 40 to 60% of total nitrogen in poultry excreta is present in the form of non-protein nitrogen (NPN) . When it is given to ruminants as feed, uric acid which is the major NPN source in poultry is degraded to ammonia by rumen microbes. The maximum inclusion rate of poultry waste in ruminant feeds is 20% [National Research Council (NRC) (1984)]. Adding broiler litter into beef cattle rations at a level of 20% or higher (as fed basis) can satisfy crude protein, calcium and phosphorus requirement . The investigators reported addition of poultry litter at a level of 30% into corn silage has beneficiary effect. Dried poultry waste contains 28% protein and 30% ash and is also an excellent source of calcium, phosphorus, potassium, iron and zinc (NRC, 1984). It was studied that poultry waste fed at levels above 35% usually covers almost the total protein requirement of sheep, and contributes substantially to the energy of the total ration (Muller, 1980). It was also noted that high copper level in poultry diet can cause toxicity in sheep. (Chaudhry et al., 1997) argued that the feeding poultry waste to livestock can cause health hazards like pathogens and residues of pesticides. Also there may be problems associated with nutrient loss mainly through volatilisation of ammonia . It is suggested that ensiling poultry waste, i.e. slaughterhouse wastes with molasses and lactobacilli improves NPN and reduces pathogens. Because material may be a potential source of pathogenic bacteria (e.g. Salmonella), moulds and yeasts , feeding of poultry waste depends on the type and standard of management of the birds.

Drying of poultry manure———

Drying in natural air conditions under sunlight is one of the most economical and feasible methods for tropical countries like India. Poultry waste has high water content, there is a need to develop a proper and inexpensive processing technology to remove excessive moisture and destroy harmful pathogens from the organic waste. Moreover, fresh poultry droppings have lower moisture content than manure from other livestock, making sun drying the most effective processing method. Dried poultry waste reportedly contains about 30 per cent protein, of which about 60 per cent is from non-protein nitrogenous sources. Drying is affected by several factors which alter its property . Thin layer (1-3 cm) drying of poultry manure is effective at temperatures within the range provided by solar heaters (40-60°C). Greater nitrogen losses (44-55 %) is observed at the deeper manure layer and higher temperature which resulted in a reduction in N:P:K from the initial value of 4.58:1.29:1 to final values in the range 2.07:1.30:1- 2.57:1.28:1. Drying is helpful in reducing the presence and offensiveness of odor by 65.3 and 69.3%, respectively, reduction in bacteria (65.6-99.8%), yeast and mold (74.1-99.6%) and E. coli (99.97 %). Dried poultry manure has high nitrogen, phosphorus and potassium contents which are essential for plant growth.

Bioenergy production-——-

Poultry manure and litter is rich in organic matter which can be transforming into bioenergy. Water flushing is one of the common processes for bioenergy production. In this technique, manure is digested anaerobically that produces a gas mixture with varying concentrations of combustible methane (FAO/CMS, 1996). Biogas is a source of energy; it can be used as a fuel for engines, generation of electricity and other energy consuming purposes. Anaerobically processed products are very much acceptable for land treatment and feed supplement. This technique is not much popular yet as it is costly, need operational feasibility and produce less biogas from poultry litter system.

Management of feathers ————

Feathers are also used in animal feed, organic fertilizers and feed supplements, as it is made up of >90% protein and is rich in cystine, arginine and threonine as they are hydrophobic amino acids, can resist from hydrothermal process that makes feather more digestible . A slow release nitrogen fertilizer has been developed from poultry feathers . It was reported that the feather-lysate produced by Bacillus licheniformis PWD-1 has nutritional property for feed similar to soybean protein. For minimizing environmental hazard new techniques are constructed for the production of biodiesel from feather meal . The nonwoven textile materials prepared by chicken feathers are very versatile and have a wide application in the field of technical textiles . Poultry feathers are also converted into biodegradable plastics by a process called polymerization. In this process, feathers which contain keratin protein are pulverized into fine dust.

Management of poultry offal ———

Poultry offals are solid by-products, wastes of poultry slaughterhouse or poultry processing plant. It includes parts and/or whole poultry carcass, undeveloped eggs, waste produced in broiler farming and slaughter house. Offal consists of 5.3% of total Kjeldahl nitrogen, 32% proteins, 54% lipids and 0.6 to 0.9 % methane production potential . According to one study, significantly higher body weight, as well as, better feed conversion ratios were found in poults fed diets with 25% poultry waste carcass meal crude protein replacement, compared with diets containing only fishmeal as a protein source The investigators concluded that levels of poultry waste carcass meal replacing the crude protein from fishmeal up to 25% appeared acceptable based upon eighth-week body weight and feed efficiency.

RECYCLING POULTRY WASTE

The use of poultry waste as a source of manure for crop production has been the preferred system for recycling nutrients. In recent years, poultry nutritionists have explored the possibility of recycling poultry waste as a feed for the poultry itself. Poultry droppings, until now considered as waste, or used sparingly as manure, may prove to be an alternative for conventional feed ingredients. Poultry excreta are commonly referred to as dried poultry droppings, cage layer excreta, dried poultry waste or dried poultry manure. Dried poultry waste reportedly contains about 30 per cent protein, of which about 60 per cent is from non-protein nitrogenous sources. It has more mineral value. Poultry waste has a high water content and there is a need to develop suitable and economical processing technology to remove excessive moisture and destroy harmful pathogens from the organic waste. It is high in fibre and low in metabolizable energy. The true digestibility coefficient of crude protein in poultry litter is about 64 per cent. Some of the constituent amino acids were found to range from 24.7 per cent (for valine) to 76.4 per cent (for serine). The absorption of calcium and phosphorus was characteristic of the individual bird and ranged from 1.2-45.3 per cent for calcium and from 7.5-46.2 per cent for phosphorus. Poultry dropping may contain various types of microbial organisms and moulds. Therefore, before poultry manure can be recycled as poultry feed, it needs processing. The drying and duration of storage may also help in altering the microbial load in fresh droppings.

DRYING

Probably the oldest method of processing waste for refeeding is the drying of poultry manure in natural air conditions under sunlight. This is the cheapest and most feasible method in a tropical country. Moreover, fresh poultry droppings have lower moisture content than manure from other livestock, making sun drying the most effective processing method. Air-drying requires varying lengths of time depending on the climate and the level of humidity. Drying the manure with heat has also been attempted. The manure may be dried at temperatures ranging from 149-385oC. Drying with heat results in a highly significant loss of energy and significant loss of nitrogen. Thin bed drying of poultry manure to 30 per cent or lower moisture levels was found to prevent the breeding of flies, to reduce obnoxious odours and to maintain the nutrient value of the manure particles. The faster the manure is dried, the higher is the nitrogen value.

HEAPING

Deep stacking of poultry waste produces considerable heat and had been shown to destroy coliforms. The maximum temperature was reportedly attained in 4-8 days. When litter from the broiler house is placed in a heap, the heat which subsequently develops is sufficient to destroy the pathogenic organisms that are present.

COMPOSTING

Collecting poultry manure in pits under cages or slat or wire floors is gaining favour as a practical and economical way to handle poultry waste. The manure may be allowed to accumulate for several years through the process of composting. Aerobic bacterial action occurs. Many compost pits have been in operation for several years without manure removal. The top foot is composed of fresh manure, the bottom foot is in an anaerobic condition and the central portion is undergoing composting. The essential requirement in managing the deep pit is that the fresh, wet material be adequately aerated to remove the moisture. To further the composting process and prevent odour, the pit must be watertight so that seepage of water cannot enter. Care must be taken to prevent drinkers from leaking or overflowing into the pit, for such overflow prevents proper bacterial action in the accumulated wet manure. When the procedure operates correctly, there is little or no odour arising from the pits and manure removal may be delayed for years.

POND DISPOSAL

Fresh poultry manure may be flushed into an open, shallow pond. Bacterial action reduces the waste material to a smaller volume. As bacterial growth occurs only during the warm months, the use of ponds is seasonal. The resulting solution may be spread in its liquid state on farmland. When aerobic action takes place, the lagoon produces little odour; but as the sludge builds up, anaerobic activity takes place and odours may be pronounced.

AERATION

The oxidation method is used for poultry by placing a continuous-flowing trough under the birds. Water is poured into the trough to keep the manure fluid and pumps keep the sludge circulating. The effluent is aerated by paddles. The addition of oxygen by the paddles increases the activity of aerobic bacteria, greatly reducing the incidence of any odours. After 4-6 months, the material is removed in liquid form and usually spread on the land. The material is practically odourless.

DEAD BIRD DISPOSAL

Dead birds must be removed from poultry houses on at least a twice-daily basis. An accurate count should be kept of birds collected and the number recorded in the farm diary. Dead birds on poultry farms should not be carelessly thrown out in the open. It will lead to the spread of infections and also cause major pollution problems. Typical methods of mortality disposal include burial, incineration, rendering, and composting. Many states have banned the use of burial pits, which historically have been used to dispose of dead birds. Incineration can be costly and raise air quality concerns, and the decreasing number of renderers further complicates disposal. Various safe means of disposing of dead birds are:

BURYING

This is a suitable method of disposal of birds for small farms that may not be able to afford to construct an incinerator. Where environmental regulations allows, a deep hole may be dug and the carcasses buried deeply so that they cannot be taken out and to prevent worms from carrying infections from the carcass to the surface of the ground. The best and easiest way is to dig a deep narrow trench. Each day’s collection of dead birds can be deposited and covered until the trench is filled. The dead birds can also be buried deep in the ground in plastic bags which will further reduce the chances of infections spreading.

PIT DISPOSAL

- This is an effective and convenient method for disposal of dead birds which is within the means of poultry raisers. A decomposition pit can be used for small losses, but care should be taken in choosing the location of the pit: • The pit should be a reasonable distance (150 feet) from the poultry houses and the well that provides the water supply. • A pit 6 feet (1.83 m) in diameter and 6 feet deep (1.83m) is large enough to take care of one 10,000-capacity broiler unit. • Contact a local government or agricultural agency to verify that disposal pits are permissible in your area • It is important that the roof or walls will not collapse easily. • Flies and other insects must not be able to enter the pit and, above all, there must be no danger of small children falling into it.

Rendering ———

Rendering is a process of application of heat to remove fat from meat (Swan, 1992). It is much suited for high-risk material disposal. Rendering products can be used in animal feed, as fertiliser or further processed via anaerobic digestion or composting. Materials are exposed to 133°C temperature for a minimum of 20 min at 3 bars or an alternative heat treatment, to make it suitable for fertilizing and feeding purposes. Heat treatment also increases the storage time of resultant products by removing moisture and killing microorganisms (NABC, 2004 Carcass Disposal). Rendered feed product can be used for chemical industry or energy source in the form of fuel. Slaughterhouse by-products are preserved with formic acid as it has a good source of proteins and vitamins and is used as animal feed . The legislation however, has become stringent about the use of slaughter by-products for animal feed to reduce the risk of disease transmission via the feed and the food chain. The main environmental concerns associated with rendering are gas and odour emissions (DEFRA, 2008) Poultry waste management is difficult and challenging, because of its linked problems, like nitrate and heavy metal contamination in crops, soil, water, air quality and odor; disposal of dead and diseased poultry and food safety. Slaughter house wastes like feathers, blood, and innards are being processed and utilized as high-protein animal feed sources or as fertilizer due to its high nitrogen content. Poultry farming in India, in spite of several challenges, has progressed drastically. Poultry industry contributes an vital role in economy of nation as well as improving the standard of living of people. The proper utilization and disposal of poultry sector will not only helping this industry but also avoiding the unnecessary discomfort to living beings and environment. The decomposition of the waste must be done with proper handing and care to avoid any risk of disease outbreak and to prevent environment pollution.

Compiled & Shared by- This paper is a compilation of groupwork provided by the

Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.

LATEST APPROACH TO POULTRY WASTE MANAGEMENT PRACTICES IN INDIA