ROLE OF IoT IN TRANSFORMING INDIAN DAIRY INDUSTRY TO SMART DAIRY FARMING

DR. RAJESH KR. SINGH,

The dairy industry in India works largely on procurement play. With an average of two cows each, dairy farmers have been the sole suppliers of milk to larger cooperatives and milk brands. In fact, most of the large brands we see are only processors and not producers of milk themselves. With businesses now setting up their own large-scale farms and owning cattle to become producers, the industry as a whole is going through major changes. By adopting the role of both supplier and producers, they are gaining an edge as they have complete control over the milk production, quality and efficiency.

Since these boutique farms already have the cattle and the capital, the only thing required to make it a profitable business is the implementation of technology. It is amply clear that the demand already exists. Technology has been the main driving force in bridging the intelligence and efficiency gap although it may not seem apparent but new technologies involving sensors and big data analytics are making farms approach light speed efficiency in how they operate.

There’s currently a huge influx of big data through sensor in the agricultural economy.

Sensors are what recognize cows through their spot patterns, internal and external behavior, nose print, width between the eyes, placement of the ear tag, or the length of their head. Information gotten from hundreds of these sensors can then be processed for autonomous machine control that matches each individual animal. Examples includes a tractor connected to an online mapping system to harvest overgrown hay, moisture precision devices placed amidst crops that can detect sunlight levels, pest pressure in the environment, water and nutrient levels.

Cattle Monitoring and Management

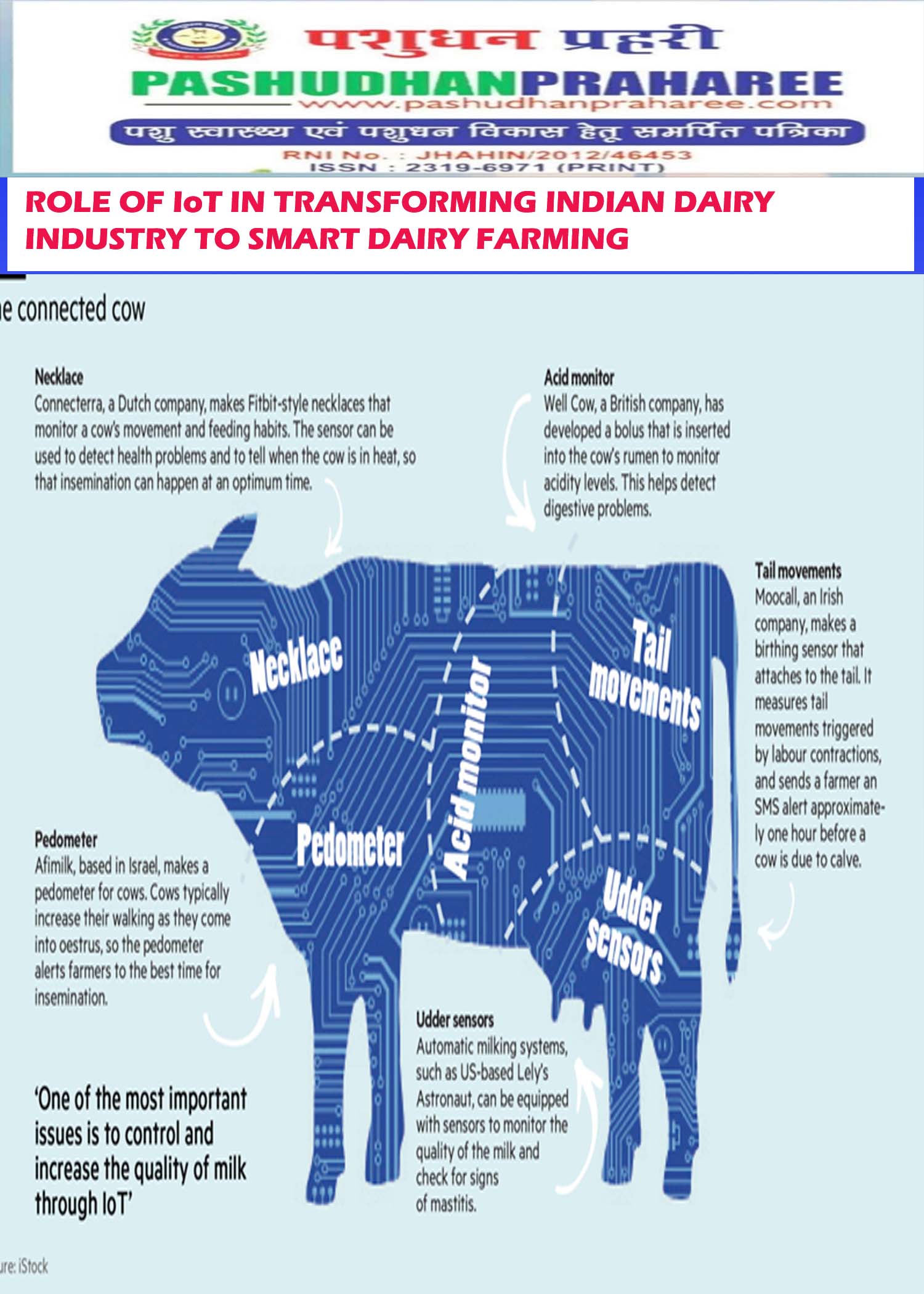

The concept of the “smart cow” might sound like an oxymoron, but the rapid development of internet of things (IoT) technology has ushered in an era when even the world’s largest companies are talking about the “connected cow” with a straight face.

Just like crop monitoring, there are IoT agriculture sensors that can be attached to the animals on a farm to monitor their health and log performance. This works similarly to IoT devices for pet care.

For example, SCR by Allflex and Cowlar use smart agriculture sensors (collar tags) to deliver temperature, health, activity, and nutrition insights on each individual cow, as well as collective information about the herd.

Digital intervention for a crucial function in dairying provides ease of operations to milk producers.

Smart dairy farming (SDF) is the key concept that can satisfy the increasing demand of quality dairy products. SDF can reduce the environmental issues, decrease the use of resources, and raise the animal health by using advanced sensing and data analyzing technologies. In order to compete in the worldwide market, the Indian dairy market needs to improve its production by using Internet of things.

A slew of tech startups are working towards digitizing the dairy supply chain, improving milk quality and production.

Dairy startups such as Country Delight , Stellapps & many more are leveraging technologies like internet of things (IoT) and data analytics to increase the production and quality of milk and expand value-added dairy offerings like cheese, butter, ghee leading to an increase in the productivity and income of farmers.

In the past few years, the Indian dairy industry has received a tremendous boost through technology-driven products, services and solutions, the credit for which deservingly goes to agricultural and dairy startups.

Some of the technologies are already in practice in India, albeit the adoption is still quite low while many others are yet to penetrate the industry. Nevertheless, there is no doubt that technology is playing a key role in modernising the Indian dairy industry.

For example Bengaluru-based Stellapps uses IoT for efficient milk production, milk procurement and cold chain management.

It assimilates this data on a cloud platform, analyses it and provides real time, actionable intelligence to all stakeholders via mobile devices. During the covid lockdown, Stellapps witnessed a 46% spike month-on-month in its order value, as the number of farmers spiked from 1.98 million to 2.3 million across 30,000 villages in 18 states, 16.6% more than pre-covid times.

Gurugram-based Country Delight delivers milk and dairy products directly from the farmer to the customer, building a fresh food brand with milk as the mode of entry to the customer’s doorstep. Country Delight has an integrated cold chain to deliver perishables like milk, curd and other dairy products fresh. Country Delight’s team delivers 3 million orders a month across Delhi, Mumbai, Pune and Bengaluru, and has grown 50 times in the last three years. The milk is delivered within 36 hours of milking, bread within 24 hours from baking and eggs delivered within 72 hours of hatching.

By year-end, it plans to add fresh fruits and vegetables that have been cultivated with precision agriculture and will be delivered within 24 hours of harvesting.

Other grocery delivery apps that deliver milk, work on a subscription-based model like BB Daily, Supr Daily and MilkBasket, where users order daily needs such as dairy-bakery products, vegetables and other essentials.

The latest entrant is Jio Mart which is said to be testing the service in a few locations.

Milkbasket’s vision is to become the default mom and pop shop for over a million households by 2021. It offers over 9,000 products across fruits and vegetables, dairy, bakery, and other FMCG categories across Gurugram, Noida, Dwarka, Ghaziabad, Hyderabad, and Bengaluru and is planning to expand further. Having achieved positive unit economics within the first six months of launch, Milkbasket claims to be the most capital-efficient model in the online grocery space as compared to its peers.

In India, a large quantum of dairy production remains unorganized.

According to analysts, the Indian dairy industry comprises 300 million herds of cattle spread across 75 million dairy farmers. These smallholder dairy farmers lack veterinary support, advice on cattle nutrition, access to optimal nutrition and animal health products, transparent markets for trading cattle and, in some cases, market access for their milk. At the same time, private dairies and dairy cooperatives struggle with sourcing milk, managing farmer payments, building traceable supply chains, and ensuring quality.

There are certain aspects of farm management which if handled through technology can reduce costs and make operations efficient. A few of them are:

The Health of the Cattle

Getting a high yield from cattle depends entirely on their health. While tracking the health of a larger number of cattle at a farm can get tough, there are trackers in the market that work the way smart watches work. These trackers monitor the heart rate and other vital signs of the cow and analyzes its health. Some of these can also track the heat period, and other aspects, just by analyzing their movement patterns. An overview of such health reports are available with the vets who help in quick response and action.

Anomalies in Milk Production

Near Field Communication, Radio Frequency Identification (RFID) and Bluetooth Low Energy (BLE) are technologies that have been in use for a long time to track the health of cows. Systems today provide animals with a unique identification number which helps track the animal’s production and understands their health patterns. Using these existing technologies, hardware installed at farms, such as milking parlors, are able to ID the cow or buffalo. Once identified, its milk production is then matched with standard patterns and production history in order to understand and identify anomalies. Identification of such anomalies can help dairies reduce losses and increase production efficiency.

Field to Yield Impact

Fodder plays a very important role in milk production, as it has a direct impact on the quality and taste of milk. The feed constitutes the major cost of a dairy’s operation. Hence, it is very important that the feed is of the best quality, to ensure a greater yield in terms of both quantity and quality. Milk processors in India pay the producers based on the fat level – higher the fat content, higher the payout. These different aspects of the feed and the yield have to be documented by the dairy farms in order to get the required information and a better understanding of the feed to yield impact. This is possible only via a collective effort by the dairies, which can happen over a period of time when more and more dairy farms become digitized. It is something that we can hope to see in the near future.

Product Lifecycle Tracking

Since the margins for milk processors are higher in case of value-added products, tracking the lifecycle of milk, to the market and the quantity that comes back – within expiry range – can make a big difference. Milk that gets returned from the market while still within the expiry range can further be converted to products like, ghee, paneer, buttermilk, curd, etc. which reduces the losses significantly and also adds to the margin. Enabling tracking of the product lifecycle, like tracking the retailers who are carrying products which are about to reach expiry and collecting them in a timely manner, through an alert system can make great difference.

Last Mile Delivery

Since the milk producers and processors both play the scale game with low margins, saving costs on every front and increasing efficiency are very important factors. Last mile delivery includes dropping off milk either to the retailer or to the house hold (in case of B2C). Both B2B and B2C deliveries require management of cold chain to avoid spoilt products and also to maintain quality. Tracking of logistics and route optimization along with temperature reporting are some simple options to do the same. In many cases, the pouches develop leaks, while the bottles and the crates used get damaged, leading to losses. These losses are not entirely avoidable, but understanding the root cause or identifying the problem areas can help in corrective measures being taken. The first step to solving a problem is recognizing that there is one.

Here are some modern gadgets and devices that will aid in boosting milk production and herd management:

Robotic cow milking equipment

“This multi-million dollar technology is by far the most well-known application of robots in the dairy industry,” said Chen Yuanrong, the founder and chairman of Blue River Nutrition. “It not only milks the cows, but it also washes, massages and feed cows.”

Whereas prior to robots, cows were only milked twice a day due to time and labour constraint; with robots, companies like Delaval robotic milking system and miRobot, provide milking systems that are able to milk multiple cows simultaneously while maintaining a clean and sanitized environment to keep the cows in healthy comfortable shape. Cows seem to enjoy getting milked three or more times as they often go back on their own free will.

Use of drones

Through aerial monitoring of land and cows grazing, farmers can respond immediately to emergencies and possibly save the life of crop or an animal. With development in battery life and autonomous flying ability, drones will be able to map, inspect/survey and photograph pasture areas where growth has been detected suitable for cow grazing.

Rotating swinging cow brush

Used for almost a decade. This is a simple rotating brush similar to one used in a carwash but made specifically to match the contours of a cow’s body.

It rotates at a comfortable speed that cows love and often queue to be next in line to use this massager. In an effort to boost cow’s comfort, research shows the rotating cow brush aid blood circulation which in turn improves milk production and child birth

Collar technology

An ID collar that sends information to the farmer through a transponder to keep track of cow’s health, milk production levels, milking frequency and how much activity the cow is getting vs. how much the cow is eating. This wearable technology is vital in individual cow management as it allows farmers to detect cow’s welfare and quite possibly respond before milk production or the herd is affected. SCR Diary is a market leader in the area of animal wearable technology which can be worn on ears, neck, legs or tail.

3D Printing

There are a multitude of applications of 3D printing in the dairy industry. A primary application is the replacement of machine parts in rural farmers will not only save valuable time but also money.

As 3D printers become more and more accessible, research is ongoing to re-engineer dairy products cutting out the use of cows itself. This means milk consumption which has been dwindling in countries like US and UK due to deficiencies such as lactose intolerance can be reversed and there will no longer be any reason to avoid it.

Health Tracking Devices for Cattle

Health disorders reduce the productivity, longevity and reproductivity of cattle. Every year, farmers cough up huge amounts of money on their cattle’s health and wellness. However, thanks to wearable animal gadgets which are akin to human fitness trackers, farmers can track, monitor and manage cattle’s health, nutrition, behaviour, pregnancy, milking frequency, milk production anomaly and activity level in real-time. These smart animal trackers can be implanted in the cattle’s ears, tail, legs, neck or any part of the body.

Last year, Karnataka government had implanted GPS-enabled digital chips in the ears of 56 lakh animals across the state to track their health and early diagnosis of medical condition. Some of the companies that have developed smart cattle health tracking devices are SmaXtec, Cowlar, Moocall, Smartbow, Stellapps, etc.

Robotic Milking Machines

Traditionally, cows have always been milked manually by hands. This is not only a time-consuming activity but also has labour cost associated with, thereby increasing the price of milk. Robotic milking machines are enabling farmers to eliminate the pressure on physical labour, maintain a hygienic milking process, milk the cows anytime of the day instead of following a fixed schedule and improve the milk production.

The robotic milking machines have arms or cups with sensors that can be attached individually to cows’ teats. The sensors can detect whether the cow or which of its teat is ready for milking or not. Once the milking starts, the machines can also identify impurities, colour and quality of milk. If the milk is not fit for human consumption, it is diverted to a separate container. The machines can also automatically clean and sanitize the teats once the task is over.

Raghava Gowda from India has developed a low-cost, non-electric milking machine for cows. Some other startups which have introduced automated milking systems are miRobot, GEA, DeLaval, Fullwood Packo and Lely among many others.

Cattle Monitoring Drones

Farmers are required to keep a manual vigilance whenever the livestock moves out of the farm for grazing. There are high chances of the cattle getting lost, stolen or being attacked by other animals. The cattle monitoring drones can keep track of the cattle and herd them back from fields to barns. Some drones are equipped with thermal sensing technology, which helps to track the cattle from the heat of their bodies. Drones can also capture the pictures of pasture areas and relay information as to whether these are suitable for cattle grazing.

A number of companies such as TRITHI Robotics, Dronitech, Sagar Defence Engineering, DJI Enterprise and Sunbirds have made headway in building commercial drones for various purposes, including for agriculture and livestock management.

Product Traceability for Customers Through Blockchain

These days, customers like to know the journey of their dairy products from farm to table. This calls for end-to-end supply chain transparency to enhance the trust of customers. An increasing number of dairy manufacturers, suppliers and other stakeholders are leveraging blockchain technology to give real-time data about their products to customers. This is done by putting a QR code on the packaging which customers can scan on their mobile devices to get information on the origin of the milk – how and where it was collected and packed, how old it is, what kind of transportation and cold milk chain facilities were used, etc.

The Kerala government in India is leveraging blockchain technology to streamline purchase and distribution of milk, fish and vegetable in the state. The international food giant Nestle has tied-up with Australian startup OpenSC to deploy blockchain technology in to improve its dairy supply chain. French supermarket Carrefour sells its micro-filtered full-fat milk in bottles with a QR code.

Some of the startups operating in food biotech are StaTwig, Ripe, AgriLedger, TE-Food and Foodcoin.

Milk Freshness

Milk is a highly perishable product. In spite of treating it with pasteurization, freezing and preservation processes, it has a tendency to go stale. Millions of tons of milk turns stale before timely consumption and goes waste. Efforts are also being consistently made to increase the shelf life of milk without adding additives or preservatives.

Technology is now making it possible to detect the freshness of milk and store it for a longer period of time. Australia-based food technology company Naturo has developed a technology that can keep natural milk fresh in the refrigerator for at least 60 days without using any additives or preservatives. US scientists have pioneered a new pasteurization technique which increases shelf life of fresh milk from 13 days to 40 days without changing its taste or nutritional value. Back home in India, IIT Guwahati scientists have developed a smartphone-app aided paper sensor kit that can test the freshness of milk and inform how well it has been pasteurized. This kit can come quite handy in large kitchens, milk collection centres and milk bars.

Automated CattleTraffic Management

It can be an extremely tedious task to manage and move cattle to milking stalls and back to barns. There is also a risk of injuries to the cattle. Automated cattle traffic management system has computer-controlled gates which opens and closes electronically. These gates can sort the livestock on the basis of their readiness to milk. The livestock ready to be milked is moved to the milking area while the others are either put in the waiting area or returned to the barns.

Companies like Delmer, Bump Gates, Fullwood Packo and Lely are known for their automatic cattle traffic systems.

Feed Management

The feed requirement of cattle depends on their health and weather. For example, a sick or pregnant cow may need more nutrition. Hot and humid weather means that cattle need more glucose in their feed.There are a number of feed technologies that produce formulated feed additives, supplements, premixes and base mixes to maintain optimal milk production throughout the year. For example, the National Dairy Development Board (NDDB) has developed bypass protein technology to produce specially treated protein supplements that can be fed to cattle to increase milk yield and quality.

Then, there are also digital feed monitoring solutions which can help farmers detect the quality of feed, manage feed inventory and understand cattle’s feeding pattern. In fact, feed monitoring solution can help design customized diet for each cow based on the assessment of their body weight, milk quality and yield, and thereby improve fertility and productivity per cow.

Some of the companies providing feed management solutions are Godrej Agrovat, DeLaval, Dairy Margin Tracker, etc.

Ecommerce Marketplaces

Several online B2B marketplaces such as AgroStar and Gold Farm have been launched in India to make modern equipment and advisory services available at the doorstep to farmers and dairy manufacturers on their smartphones. Many B2C platforms such as FreshVnF, WayCool and FarmLink have also emerged at a rapid pace – they pick fresh produce from farms and deliver them at the doorstep of retail customers, hotels, restaurants and cafes.

Supply Chain Technology

The Indian dairy industry supply chain is quite complex owing to its dependency on a number of factors such as storage temperature, cold chains availability, weather, perishability/shelf life, first and last-mile distance, packaging, etc. The fact that the Indian dairy industry is unorganized and fragmented also adds to the supply chain woes. However, a number of technological innovations are taking place in the dairy supply chain in India.

Take, for example, India-based supply chain startups such as Stellapps, MilkManApps and Trinetra Wireless.

Under supply chain, cold chain technology is expected to progress by leaps and bounds. The coming years will witness the rise of energy-efficient and cost-effective cold chain warehouses, cold boxes, Phase Changing Material (PCM) pads, temperature-controlled cold chain packing, refrigerated vehicles, cold chain pallet shippers, and other advanced cooling technologies. Tessol and Warehouse-India startups are making their mark in cold chain infrastructure in India.

Farm Management Technology

From accounting, finance and labour management to livestock and supply chain management, a dairy farm has to ensure that all its operations run seamlessly. Farm management software can help automate and digitize end-to-end production and operations activities. It can give a holistic view of all farm activities, manage records, generate reports and detect inefficiencies.

Stellapps, Milc Group, My Dairy Dashboard and Nedap are some of the smart farm management solutions that exist currently.

Biotechnology

Biotechnology is a relatively emerging field in the dairy industry. However, it is being touted as one of the most disrupting dairy technology of the future. The potential of dairy biotechnology lies in the areas such as increasing disease resistance in livestock, scientific feeding of cows, embryo transmit technology, artificial insemination, development of new molecules and vaccines for prevention and disease management of animals, dairy enzymes/proteins/probiotics, food-grade bio-preservatives, etc.

Some of examples of dairy biotechnology products that have made headlines are animal-free ice cream by Perfect Day, livestock disease diagnostic tools by Advanced Animal Diagnostics, bovine genetics breeding by Genus ABS India, etc.

The above list of technologies is inclusive but not exhaustive. Currently, most dairy technologies face adoption barriers in India because a large percentage of the Indian dairy industry still comprises of small-scale and unorganised players who lack financial means, accessibility and expertise to deploy the technology. The good news is that dairy technological revolution has already begun in India, and it’s only a matter of time that these technologies become common.

Smart Dairy Farming

Dairy farmers are in the era of precision farming which is considered to be more important for information provision and for capturing competitive market, hence the need for a variety of data sources that contain the dynamic and static cow data about feeding, calving, nutrition, insemination, and the process of milk production. Internet of things started influencing the milk production. This step should necessarily be taken to meet the demand for dairy for huge population of the world. These are almost the last decades when the milk demands are fulfilled without the help of the latest technology; after that it will not be possible to encounter the demands for dairy and dairy products without technology. It is always considered as a challenging task to decide the correct time for milking the cow. Lack of technology can cause the milk to be perishable and fragile. In this matter, IoT can support farmers with wearable sensor devices to keep them aware of the status of every cow. The sensor-based system can effectively and correctly detect the illness of the cow, before it effects the milk production. The farm owner can place the sensor onto the cow’s neck, tail, or leg for acquiring real time data to examine numerous factors like cow’s behavior, activity, health, feed consumption, milk production, and fertility management. These wearable sensors can spot cow’s illness and diseases such as mastitis or any other disease that can reduce milk production. The smart dairy farming includes real time sensors that collect data from cows with the help of wearable smart collars, machine learning data analysis, and cloud-based data centers that manage data and support the farmer in order to manage quality of dairy products. The use of hardware and package will increase the productivity of the farming trade to satisfy the challenges it faces by assembling completely different information points to boost the industry’s production. This technology is additionally harmless to the atmosphere and to the cows; thus it appeals to several completely different folks and teams, in contrast to the genetically changed hormones and alternative harmful and unnatural additives that are usually added to extend productivity. Smart farming is not just monitoring; it is also related to proper business management. By gathering raw data like insemination moment, pregnancy, or calving time, this data is used for value information and for applying some probability and statistics to plan the future work and manage dairy farm properly. In the example of a cow, technology can inform a farmer about the day of estrus, insemination, and parturition and can also calculate the age at initial parturition and the parturition interval between ordered parities.

Internet of things and data-driven techniques are creating greater opportunities for smart dairy farming. Different features and their benefits are described as follows-

1.Geofencing

Geofencing is an area-based technique in which an application or other programming techniques can utilize GPS, RFID, Wi-Fi, or cell information to trigger a premodified activity when a cell phone or RFID label enters or leaves virtual limit setup around a topographical area, known as a geofence.

In dairy farming, a farmer equips a herd of cattle with hardware device which consists of different sensors and GPS tracking unit. Sensors are used to track down animal health and other key behavior to increase output and overall animal wellness. Geofencing uses GPS network and other related means like Wi-Fi nodes and Bluetooth beacons to create a geofence around the farmer area; then the geofence is paired with animal collar and software application, and when the animal leaves that specific area, it triggers the alerts for the farmer.

- Automatic Disease Detection

In dairy farming animals can get various diseases due to numerous reasons. When there are a lot of animals, to check every animal daily is impossible and time consuming. It is a lengthy process and a difficult task to do individually and manually, and the animal’s disease is also contagious, so if not caught in time, the other animals can also be infected, causing loss. Yield of milk can also be monitored and controlled, and any minute change in animal behavior can also be recorded. Therefore, to cater for this situation and find automotive way of monitoring animals’ health, we move towards automatic disease detection.

An animal suffering from any disease changes its daily routine habits like lying down on different area, splitting itself from herd, or changing its eating habit. Sensors that detect changes in animal body make it easy for a farmer to detect and treat that animal. Mounted sensor can sense the behavior of an animal and keep record of it. These types of records help us in making future decisions like calling a doctor. Any abnormality in this pattern is easily detected with the help of sensors, and the farmer will be alerted through messages or other means. For example, the farmer can analyze any disease with the help of accelerometers measuring animal movement, and activities can be captured, for example, whether the animal is less active compared to its daily routine. Just like any other sensors (e.g., temperature sensors, load sensors, microphones, and heartbeat sensors), these sensors can record animal daily life behavior such as disease symptoms, temperature change, mooing, body weight changes, and pulse rate change.

3.Milking

Manual milking in a dairy farm is very time consuming and slow procedure. The preserving process of milk is also not hygienic. Manual process can cause bacterial infection in milk. IoT has solved this problem more efficiently, reducing cost and manpower, by introducing automilking. If the temperature is not favorable, the chances of milk getting spoiled are very high, but automilking can automatically preserve the milk by using different smart cooling tanks. Common automilking systems rely on two components: computer and special herd management software. Automilking is further divided into several tasks like collecting the animal, cleaning the animal before milking, attaching the milking equipment, extracting milk, removing the equipment, and routing the animal out of the special area. Milk production is dependent on the amount and quality of food given to the animals. Every cow in herd is different; some can be suffering from any disease, some are immature, or some can be pregnant. Each cow has its own amount of nutrients requirement. To ensure that required nutrients are given to the animal, this cannot be done by simply looking at fodder; rather it has to be processed through a mechanized system that will show the amount of carbs and proteins given to the cow.

4.Automatic Water and Food Supply

Water is an important nutrient for all animals. For the welfare and profitability of the animals, it is important that cows should have sufficient quality water. Milk contains almost 87% water. The water requirements are closely related to milk production, the moisture content of the feed, and environmental factors such as air temperature and humidity. The maximum cattle water supply network normally occurs during the highest feeding period. Automatic irrigation system is standard in most farms because it is practical and efficient. The system consists of an insulated floor and a heated bowl, which automatically fills with water from a pressure line. A float valve regulates the water level in the bowl. A thermostat set to 4 to 6° C regulates the water temperature in the bowl.

Food is necessary for nutrition because it determines the amount of nutrients available to the animal for health and production. Actual or valuable food prevents underfeeding or overfeeding of nutrients and promotes the effective use of nutrients . Underfeeding of nutrients limits production and may affect animal health. Overfeeding of nutrients increases feed costs, can lead to excessive nutritional load of the environment, and can be too toxic or dangerous to health.

Reference-On Request