Silage: A Promise Throughout the Year Availability of Fodder

Neelam Kumari and Nutan Chauhan

During monsoon and winter, we have an abundant supply of grass and other green fodder and during summer, green fodder availability is less. Traditionally, farmers use store-dried paddy as hay and maize stalks as kutty and it is used as dry fodder during the summer months. But due to drying nutritional value of fodder is decreased and it is unpalatable.

The conservation of surplus fodder during the flush season as hay or silage is a practical method to provide quality fodder supply to livestock throughout the year. Silage is the best way to preserve fresh fodder with the fewest losses considering the actual climatic conditions.

Silage can be defined as the product obtained by controlled fermentation of grasses, green fodder, crop residues or forages having high moisture (DM-28-34%) content under anaerobic conditions. The process of silage making is known as ensiling and the container which is used for silage making is known as silo. Silage has all the nutrients of green fodder and tastes good and stored silage can be used during summer. Silage quality can be improved by the incorporation of additives. eg.- fermentation stimulant, fermentation inhibitor etc.

Classification of silage

| S. No. | Quality Parameter | Very good quality silage | Good quality silage | Bad quality silage |

| 1. | pH | 3.5-4.2 | 4.4-4.6 | >4.6 |

| 2. | Ammonia Nitrogen (% of total nitrogen) | <10% | 10-20% | >20% |

| 3. | Butyric acid content | <1% | 1-3% | 3-6% |

Fermentation type

| S. No. | Good quality silage | Bad quality silage |

| 1. | Lactic acid is the product of fermentation | Butyric acid is the product of fermentation |

| 2. | In this water-soluble carbohydrate is used as a substrate | Protein is used as a substrate |

| 3. | Fruity odour | Bad smell |

| 4. | Colour of this type of silage is greenish brown | Colour of this silage is dark brown |

| 5. | Plant structure is maintained as such | Plant structure is lost |

Advantages of silage-making

- Better use of green fodder throughout the year.

- Silage retains all the nutrients of green fodder and the fermentation process improves silage tastes or makes it more palatable.

- Silage is the pre-fermented feed so it improves digestion and absorption of nutrients.

- Silage reduces the requirement for concentrate feeds and increases profitability.

- Silage retains up to 85 % of the nutritive value of the crop from which it is made.

- Silage can ensure the supply of quality forage in the lean period. When green production is in excess, it can be preserved for future use by silage making.

- Less space is required for storage and a cubic foot of silage contains about three times more dry weight of feed than a cubic foot of long hay stored in the heap.

Characteristics of the crop for silage making

- Crops have a good percentage of sugar and appropriate dry matter content (28-34% dry matter and water-soluble carbohydrate is 7-10%DM).

- Non-leguminous crops are more suitable for silage making. Eg.- maize, jowar, bajra, because of low buffering capacity.

- Crops should be harvested at the pre-flowering to flowering stage.

- High moisture crops can be dried in sunshine for 4 hours to reduce moisture content or some dry hay or straw up to 5-20% can also be added.

- If the crop is over ripe and too dry than add water during packing silo.

- If crop having low water-soluble carbohydrate, then add molasses @ 2-3% of weight of fodder.

- Cereal forages can be enriched for nitrogen (protein) content by spraying urea at the rate of 0.5 to 1.0 percent of fresh forage.

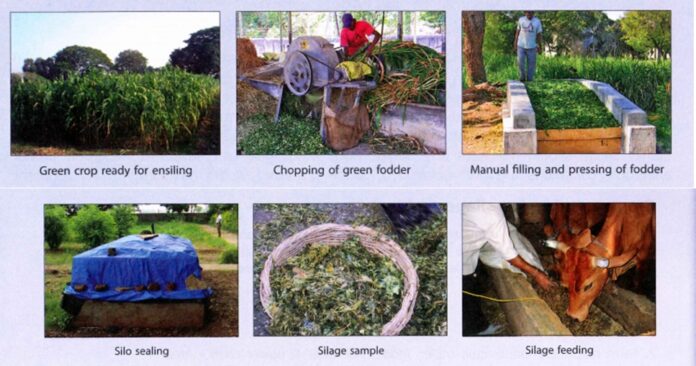

Silage making process

Firstly, a silage pit has to be dug for storing silage. The Size of the pit can be determined based on the amount of silage; you want to make. A pit having a dimension of 1-meter wide × 1-meter length ×1-metre depth can store 500 kilograms of silage. The pit must be located where water does not stagnate during rains. Surround the pit with thick plastic sheets or construct the pit using bricks and cement

Filling and sealing of the silo pit

- The filling process of the pit should be rapid with proper pressing using a tractor after each filling to remove air.

- Silo pit filling should be completed within 4-7 days.

- After thorough pressing, the top should be covered with polythene followed by a soil layer of 5- 6 inches in depth.

- Top of the silo pit after filling and compressing should be higher than the surrounding. Plug all possible areas of air or water entry.

Removing silage from the pit

- Silage should be ready within a period of 3-4 weeks of sealing.

- Once opened the pit should be fed completely.

- Silage may be fed from the top, layer by layer, daily.

- When silage is exposed to air for a longer period silage get spoiled. Hence, try to prevent entry of air.