Standard of Air Pollutants In Relation To Animal Production

Air pollution is a growing concern worldwide, impacting not only human health but also the well-being of animals. In the context of animal production, air quality plays a critical role in ensuring the health and productivity of livestock. Poor air quality can lead to a range of issues, including respiratory diseases, reduced growth rates, and decreased reproductive performance in animals. Therefore, establishing standards for air pollutants in relation to animal production is vital to safeguard animal welfare and optimize livestock productivity. In this comprehensive article, we will explore the key air pollutants that affect animal production, their sources, the impact on livestock, and the standards and regulations in place to mitigate these effects.

The effect of air pollutant on animal production system is well established but acceptable upper limits firmly exist (Wathes et al., 1983). The standard for protection of human being against occupational and industrial workplace has often been suggested as appropriate guidelines for housed animals. Very few report are available regarding air quality parameters to which animal are exposed in total confinement housing and their effect on animal health and production. The threshold limit value for time- weighted average concentration for a normal 8 h day/40–h week, or major gaseous contaminants are 5000, 25 and 10 ppm for CO2, NH3, and H2S respectively (American conference of Governmental Industrial Hygienists, 1984). However a recent report for the Commission Internationale du Geneie Rural by the Scottish Farm Building Investigation Unit (SFBIU, 1984) recommended maximum concentration for CO2, NH3 and H2S in animal housing of 3000, 20 and 0.5 ppm respectively. But H2S concentration level may be permissible to 5 ppm at the time of manure removal. To design environmental control system for animal housing to meet specific air quality standards requires information on the rates of production of the individual contaminants within them. However, data are not available at present on such rates and the effects of management’s practices and housing system (Scott et al., 1983).

CRITICAL TEMPERATURE

An optimal thermal environment is usually defined for each species in terms of its effects on production. There are a few specific recommendations in terms of disease. Several authors have discussed and reported the effects of temperature on the milk yield of dairy cows (Webester,1981; Neumann and Kliche, 1988), the performance of fattening pigs (Hann and Nienaber,1988) and the egg yield of laying hens (Charles,1984). The lower critical temperature (LCT) defines the lower limit of the range of optimal temperature. The upper limit is given by the upper critical temperature (UCT). LCT is affected by factors such as age, sex, breed (Henken et al., 1991) food energy level and intake, feathering (Macleod,1984), stocking density (Burmester,1986), bedding system (Bruce,1981) etc.

STANDARD OF AIR POLLUTANTS

Temperature

Ambient temperature as the only indicator of animal comfort, thermal indices has been developed to better characterize the influence of multiple environmental variables on the animal. The temperaturehumidity index (THI), first proposed by Thom (1959), has been extensively applied for moderate to hot conditions, even with recognized limitations related to air speed and radiation heat loads (NOAA, 1976). At the present time, the THI has become the standard for classifying thermal environments in many animal studies and selection of management practices during seasons other than winter (Hahn et al., 2003). The THI has further been used as the basis for the Livestock Weather Safety Index (LWSI; LCI, 1970) to describe categories of heat stress associated with hot weather conditions for livestock exposed to extreme conditions. Categories in the LWSI are alert (74 < THI < 79), danger (79 ≤ THI < 84), and emergency (THI ≥ 84). Additionally, THI between 70 and 74 is an indication to producers that they need to be aware that the potential for heat stress in livestock exists. Animal room should be design in such a way that in both winter and summer season temperature should be fully controlled and continuously maintained. It should be monitored by instrument at least once a day. The target should be to maintain the room temperature in a band width of 40C. If animal’s thermoregulatory ability has been affected by anesthesia or other scientific procedures, a higher room temperature or more bedding materials should be provided. But in some species shade or shelter will be required in the summer and additional food, heat as well as shelter in winter to maintain the constant temperature.

Relative humidity

The extreme variation in relative humidity can have adverse effects on the well-being of animals as well as affecting the rate of heat loss. So it can also influence activity and food intake. The RH in animal’s room should be maintained at 55% ±10%. Prolonged period below 40 % and above 70 % can adversely affect the animal’s performance. Chickens are more tolerant than mammals and a range of 30-70% is acceptable. Too low humidity in the air will cause irritation of the mucous membranes, while too high humidity may promote growth of fungus infections. High humidity may also contribute to decay in structures. If possible keep the relative humidity in the range of 40 to 80%.

Ventilation

Ventilation systems are required in animals housing for following purpose: To regulate the temperature and humidity in prescribed limit To reduce the levels and spread of odours, noxious gases dust and infectious diseases. To provide appropriate and sufficient air quality. The ventilation rate should be related to its stocking density and heat generated by animals and equipments in the rooms. In fully stocked room for rodents and lagomorphs, 15-20 changes of fresh or conditioned air per hour distributed throughout the room are normally adequate. For cats, dogs, and primates, 10- 12 changes per hour may be adequate. In general ventilation system can be used to create differential air pressure within the buildings as part of barrier system. Clean areas are generally maintained at higher pressure and hazards areas at low pressure than those adjacent to them to minimize the leakage of dirty air into cleaner areas and the escape of air borne hazards air outside the premises. Ventilation rates in enclosed facilities (MWPS, 1989, 1990) should increase from a cold-season minimum (to remove water vapor, contaminants, and odors as well as modify inside temperature) to a hot-season maximum (usually around 10 times the minimum rate, to limit the increase in temperature inside the house that is due to the solar radiation load and sensible animal heat). It is important to recognize the approximately 10-fold increase in ventilation rate from winter to summer that is required in a typical livestock or poultry house. Because the animals themselves are the major source of water vapor, heat, and (indirectly) odorous matter, ventilation rate calculated on the basis of animal mass is more accurate than that based on air exchange rate guideline. During cold weather, ventilation in houses for neonatal animals should maintain acceptable air quality in terms of water vapor and other pollutants without chilling the animals. Air speed should be less than 0.25 m/s (50 ft/min) past very young animals. There should be no drafts on young poultry or pigs. During hot, warm, or cool atmospheric conditions, ventilation of animal houses should maintain the thermal comfort of the animal to the extent possible. Ideally, the ventilation rate should be high enough to prevent indoor temperature from exceeding outdoor temperature (temperature rise limit; Curtis, 1983) by more than 3°C (5°F) when the atmospheric temperature is above 32°C (90°F) for small animals and above 25°C (78°F) for larger ones. In arid and semi-arid regions where the potential for evaporative heat loss is great, air temperature may peak at over 43°C (110°F) for 1 or 2 d or longer without affecting animal well-being if animals have been acclimatized by chronic exposure. So Ventilation system design should be based on building construction and the rates of water vapor and heat production of the animals housed (Curtis, 1983; Hinkle and Strombaugh, 1983)

Air Movements

Air movements will assist in heat loss by evaporation and by conduction/ convection as long as the air temperature is lower than the skin temperature. When the air temperature approaches the skin temperature rapid air movements are experienced as comfortable, but at low temperatures it will lead to excessive cooling of unprotected skin areas (cold draught). In addition air movements are required to remove noxious and toxic gases and to supply the animal with fresh air for breathing. A wind velocity of 0.2m/s is generally regarded as a minimum requirement, but it can be increased to 1.0m/s, when the temperature is nearing the upper critical, or more when it goes beyond that.

Lighting

Lighting system is more important for nocturnal and crepuscular mammals. The light intensity, wavelength, and photoperiod are important aspects for better performance of animals. The intensity of light should be range 350-400 lux in most of laboratory houses. The wavelength have little role on animal production and adverse effect has been reported. To regulate circadian rhythm and breeding cycles in animals, the light to dark ration should be maintained properly. The circadian clock of some species may be affected as much by light pulses of less than one second during the dark phase as by a long photoperiod.

Dust particle

The dust in animal housing originates from the feed, the bedding material and from the animals themselves. A small amount enters the animal house with the incoming ventilation air. The dust particles are carriers for gases, microorganisms, endotoxins and various other substances such as skin cells and manure particles (Donham, 1989). Animal house dust consists up to 90 % of organic matter (Aengst, 1984).The amount of airborne dust fluctuates greatly both in the course of a day and according to the type of animal. Recent investigations carried out in 329 animal houses in four different EU countries revealed the dust concentrations. The results are given in 24 hours mean values for inhalable and respirable dust (TAKAI et al., 1998). The highest dust concentrations are found in poultry housing followed by pig and cattle. Most of this dust may leave the animal houses by way of the exhaust air and is distributed in the surroundings. Assuming a mean dust concentration of 2 mg/m3 in the exhaust air of a piggery housing 1000 fattening pigs and a mean ventilation rate of 200 m3 /LU per hour (1 LU- livestock unit= 500 kg live weight) throughout the year the total dust emission per year will be about 500 kg. The emission rate of respirable dust from piggeries is about 60 mg/LU/ hour. Presently it is unknown how far these fine particles are distributed in the environment of animal houses (Hartung, 1998).The health effects of dust particles depend very much on the nature of the dust (organic, inorganic), the compounds the particles are carrying (bacteria, toxins) and the diameter of the particles. Particles with aerodynamic diameters smaller than 5 µm can penetrate deep into the lung. The larger particles are deposited in the upper airways. High dust concentrations can irritate the mucous membranes and overload the lung clearance mechanisms. Together with the dust particles microorganisms can be transported into the respiratory system causing infections. Endotoxins can trigger allergic reactions in the airways of susceptible humans, even in low concentrations.

Bioaerosol

Under commercial production the airborne particles will contain a mixture of biological material from a range of sources. The chickens produce large amounts of dust as a result of epithelial desquamation, as well as from feed, manure, faeces and litter (Matkovic et al., 2009). This dust consists of a variety of airborne particles of biological origin, i.e. bacteria, fungi, endotoxins (lipopolysaccharide, LPS) of Gram-negative bacteria, 1.3-beta-glucan of fungi, fungal spores and mycelium fragments. The particles in a bioaerosol are generally 0.3 to 100 µm in diameter; however, the respirable size fraction of 1 to 10 µm is of primary concern. Bioaerosols, ranging in size from 1.0 to 5.0 µm, generally remain in the air, whereas larger particles are deposited on surfaces (Srikanth et al., 2008).

Microorganisms and endotoxins in animal houses

Microorganisms and endotoxins belong to the prominent aerial pollutants in farm animal housings which have been linked with several production diseases (Wathes, 1994;Hartung, 1994). It has been assumed to pose a risk for the health of farmers and workers in the farms (Donham, 1990) and to the neighboring residential areas around intensive livestock enterprises. Concentrations of airborne microorganisms are particularly high in pig and poultry houses (Clark et al., 1983; Cormier et al., 1990; Ewerth et al., 1983).Usually microorganisms and endotoxins (lipopolysaccharides, LPS) are associated with dust particles and present a biologically active aerosol (bioaerosol). The quantities of bacteria in animal house air can be very high at times but show vast variations which depend on daily and seasonal influences as well as on the animal species and on the keeping and management system (Müller and WIeser, 1987). Another crucial problem when measuring airborne microorganisms is the sampling method. At present there is no generally accepted standard sampling procedure available. Total counts of bacteria, Gram negative bacteria (Enterobacteriaceae) and fungi and yeasts were of general concern. The highest bacteria concentrations were detected in broiler houses. Concentrations of about 6.43 log CFU per m3 air on average were found during the day as well as during the night. In contrast to broiler houses, houses for laying hens had lower concentrations of between 4 and 5 log CFU per m3. For pigs, average concentrations of 5.1 log CFU per m3 and for cattle of 4.3 log CFU per m3 were detected. In all cases the concentrations were greater in the day than at night. This diurnal distribution was also observed for Enterobacteriaceae with the exception of layers. The overall concentrations differed during the day between 3 and nearly 4 log CFU per m3. Only fattening pigs and layers had higher yields of Enterobacteriaceae, ranging between 4.2 and 4.7 log CFU per m3. In cattle houses, concentrations of 2.3 log CFU per m3 and in pig and poultry houses 3.9 log CFU per m3 observed. The mean daily fungi concentration was 3.8 for cattle, 3.7 for pigs and 4.0 for poultry log CFU per m3, respectively. During the night, the mean fungi concentration was 3.6 for cattle, 3.8 for pigs and 3.7 log CFU per m3 for poultry. Based on the concentration of airborne microorganisms, the measurements were ranked by animal type. During the day and night, broiler houses had the highest concentrations of total bacteria and of fungi, while the highest concentrations of Enterobacteriaceae were recorded during the day in fattening pig units. The highest concentration was found during the night in houses for laying hens. Compared with pigs and poultry the ET concentration in cattle houses was low. For inhalable ET, mean concentrations ranged between 7.4 and 63.9 ng m3 and for respirable ET, concentrations ranged between 0.6 and 6.7 ng m3. Mean ET concentrations were higher for pigs. Inhalable ET concentration ranged between 52.3 and 186.5 ng m3with related respirable ET concentrations of between 7.4 and 18.9 ng m-3 . Concentrations were highest for poultry; mean values ranged between 338.9 and 860.4 ng ET m3 air in inhalable dust fractions and from 9.6 to 58.1 ng ET m3 air in respirable dust. The overall percentage of the RD/ID ratio differed between species, ie. 8.6 % for cattle, 8.8 % for pigs and 5.7 % for poultry. For the RN/IN ratio, values of 13.9, 12.2 and 9.0% were calculated, respectively. For the same dust fractions significant variations between the different housing types were estimated.

BACTERIAL COUNTS

The research work carried out for the evaluation of microbiological air contamination in some barns (cow sheds, pig sties, poultry houses) and dairy buildings. The emission levels of bioaerosols from chosen farming objects into atmospheric air were also estimated. Air sampling was carried out in rural areas in Podlasie in January and February (Karwowska, 2004).

Two kinds of barns were taken into account:

Modern type — exploited for less then10 years, with mechanical ventilation, improved feeding systems, without or with thin-layer bedding (cow sheds I and II, pigsty IV) Conventional type — older ones, without ventilation systems (only natural ventilation), with traditional bedding and feeding methods (cowshed III, pigsty V, poultry houses VI and VII). Temperature of atmospheric air ranged between -2°C and +1°C; temperatures inside barns and dairy objects was 10-12°C and 7-13°C, respectively. Relative indoor air humidity was about 80-90%, and of atmospheric air 37%.It has been stated, that the number of microorganisms(as CFU/m3) in barns ranged between 1.7×103-8.8×104 for mesophilic bacteria, 3.5×101-8.3x102for hemolytic bacteria, 1.5×103-4.6×104 for staphylococci, 5×100- 2×102 for coligroup bacteria and 1.7×102- 2.4×104 for moulds.The most significant microbiological contamination has been detected at sampling point number IV (a modern pigsty). High amounts of mannitol+ staphylococci occurred in pigsties (IV, V), cow shed (II) and poultry house (VII). In some cases (II, V, VII) the number of staphylococci was higher than the number of mesophilic bacteria on MPA agar. Two cow-sheds (I, II), one pigsty (IV) and one poultry house (VII) were strongly contaminated with moulds.

Air Pollutants and Their Sources

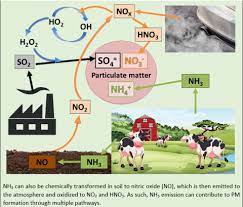

- Ammonia (NH3)

Source: Ammonia is primarily released from animal waste, including urine and feces. It can also originate from the application of manure and fertilizers.

Impact on Animal Production:

- Respiratory Issues: Ammonia can irritate the respiratory tracts of animals, leading to coughing and reduced lung function.

- Reduced Feed Intake: High ammonia levels may cause animals to reduce their feed intake, resulting in slower growth rates.

- Impaired Reproduction: In dairy cows, elevated ammonia concentrations have been associated with decreased fertility.

Particulate Matter (PM)

Source: Particulate matter consists of tiny particles or droplets in the air, which can originate from various sources, including combustion, dust, and agricultural activities.

Impact on Animal Production:

- Respiratory Distress: Inhaling particulate matter can cause respiratory distress and lung damage in animals.

- Reduced Weight Gain: Prolonged exposure to high levels of PM can result in reduced weight gain in livestock.

Volatile Organic Compounds (VOCs)

Source: VOCs are released from various sources, including manure, feed, and building materials in livestock facilities.

Impact on Animal Production:

- Respiratory Problems: VOCs can irritate the respiratory system of animals, leading to coughing and discomfort.

- Reduced Feed Efficiency: In poultry, exposure to VOCs can reduce feed efficiency, resulting in increased production costs.

Methane (CH4)

Source: Methane is primarily produced during enteric fermentation in ruminant animals like cattle and sheep.

Impact on Animal Production:

- Energy Loss: Methane production is associated with energy loss in ruminant animals, reducing their feed efficiency.

- Reduced Productivity: Elevated methane emissions can result in lower milk and meat production in cattle.

Hydrogen Sulfide (H2S)

Source: Hydrogen sulfide can be released from animal waste, particularly in confined spaces with poor ventilation.

Impact on Animal Production:

- Respiratory Distress: Inhalation of hydrogen sulfide can lead to respiratory distress and lung damage in animals.

- Reduced Productivity: High H2S levels have been linked to decreased growth rates and egg production in poultry.

Carbon Dioxide (CO2)

Source: Carbon dioxide is a natural component of the atmosphere and is produced during animal respiration.

Impact on Animal Production:

- Ventilation Needs: High CO2 levels can necessitate increased ventilation in animal housing to ensure adequate oxygen supply.

- Heat Stress: Elevated CO2 concentrations may contribute to heat stress in animals.

Air Quality Standards and Regulations

Regulatory bodies and organizations around the world have established air quality standards and guidelines to address the impact of air pollutants on animal production. These standards aim to protect animal welfare, promote sustainable livestock farming, and minimize the environmental footprint of agriculture. Here are some of the key regulations and standards:

United States Environmental Protection Agency (EPA)

In the United States, the EPA has established regulations under the Clean Air Act that address emissions of ammonia and hydrogen sulfide from concentrated animal feeding operations (CAFOs). These regulations include the requirement for CAFOs to develop and implement air quality monitoring and management plans.

European Union (EU)

The EU has developed directives and regulations that set air quality standards for various pollutants, including ammonia and particulate matter, near livestock facilities. These standards aim to protect human and animal health while promoting sustainable livestock production.

World Health Organization (WHO)

The WHO provides guidelines on acceptable levels of various air pollutants, with a focus on safeguarding public health. While these guidelines are not specific to animal production, they indirectly benefit livestock by reducing potential health risks to farmworkers and nearby communities.

National and Local Regulations

Many countries have their own national regulations and standards related to air quality in the context of animal production. These may include emissions limits, setback distances for livestock facilities, and requirements for air quality monitoring.

Strategies for Mitigating Air Pollution in Animal Production

To meet air quality standards and regulations and improve the well-being of animals, several strategies can be implemented:

- Improved Manure Management

Implementing efficient manure management practices, such as proper storage, treatment, and application, can significantly reduce ammonia emissions and mitigate the release of other pollutants.

- Ventilation and Building Design

Optimal building design and ventilation systems can help dilute and remove air pollutants from livestock facilities. These designs should consider factors like animal density and environmental conditions.

- Nutritional Interventions

Modifying animal diets can reduce enteric methane emissions. For instance, the inclusion of feed additives or the adjustment of dietary components can improve feed efficiency.

- Alternative Housing Systems

Innovative housing systems, such as pasture-based and free-range systems, can help disperse air pollutants and reduce the concentration of emissions in confined spaces.

- Green Technology

The adoption of green technologies, such as anaerobic digesters and biofilters, can capture and treat air pollutants from livestock operations.

Conclusion

Air quality standards in relation to animal production are crucial for safeguarding animal welfare, promoting sustainable farming practices, and mitigating the environmental impact of agriculture. Understanding the sources and effects of air pollutants on livestock is essential for developing effective strategies to meet these standards. By implementing proper manure management, improving ventilation and building design, adjusting animal diets, exploring alternative housing systems, and adopting green technologies, the livestock industry can ensure that air quality standards are met, benefiting both animals and the environment.In recent years the increasing use of intensive livestock production systems has become a source of solid , liquid and air borne emissions that can be both a nuisance and environmentally harmful. The most important greenhouse gases are methane (CH4), nitrous oxide (N2O ) and carbon dioxide (CO2 ) . In spite of the low amount of CH4 in the atmosphere relative to that of CO2, its importance as a pollutant is considered to be 21 times greater than that of CO2 , while that of N2O is 310 times greater (Hartung, 2003).There are loads of dusts, microorganisms and endotoxins present in animal house air. These substances are emitted in considerable amounts from buildings and manure stores which lead to health risk for animal and man. Suitable abatement techniques for gases such as ammonia and particulates are available. But these should be employed in practice. There is still a considerable lack of knowledge on the distribution and health effects of airborne particulate emissions from livestock sources in the environment. For licensing new animal farms as well as residential areas in the farming environment more precise information on the travel distance of harmful particles and compounds are required.

Compiled & Shared by- This paper is a compilation of groupwork provided by the

Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.