TETRA PAK : A WONDERFUL INVENTION FOR MILK & MILK PRODUCT PACKAGING AND INNOVATION IN PACKAGING TECHNOLOGY

India is leading milk producing country in the world, accounting for 19 percent of the global market share and expected to grow at compound annual growth rate (CAGR) of 14.8% between FY 2018 – 2023. As per fiscal year 2019, milk production in India amounted to about 187 million metric tons. As per FY – 2018, around 81% of the Indian dairy and milk processing market comes under unorganized sector, where milk is processed in unhygienic infrastructure, which affects the overall quality of milk and milk-based products. Consumption patterns of liquid milk at the farm level and less infrastructure for processing is the main reason for low value addition of milk. The demand for value added products especially traditional dairy products is increasing day by day and the dairy industry of the country is trying to meet the present demand. Uttar Pradesh, Rajasthan and Gujarat are the major milk producing states in India. Uttar Pradesh is the largest milk-producing state, as it has the highest buffalo population and the second-highest cattle population in the country. Majority of the rural population in this state is engaged in livestock nurture and dairy farming. Gujarat holds several cooperative dairy unions, milk cooperative societies and private dairy plants, which play vital roles in the production of milk and milk-based products in the state.

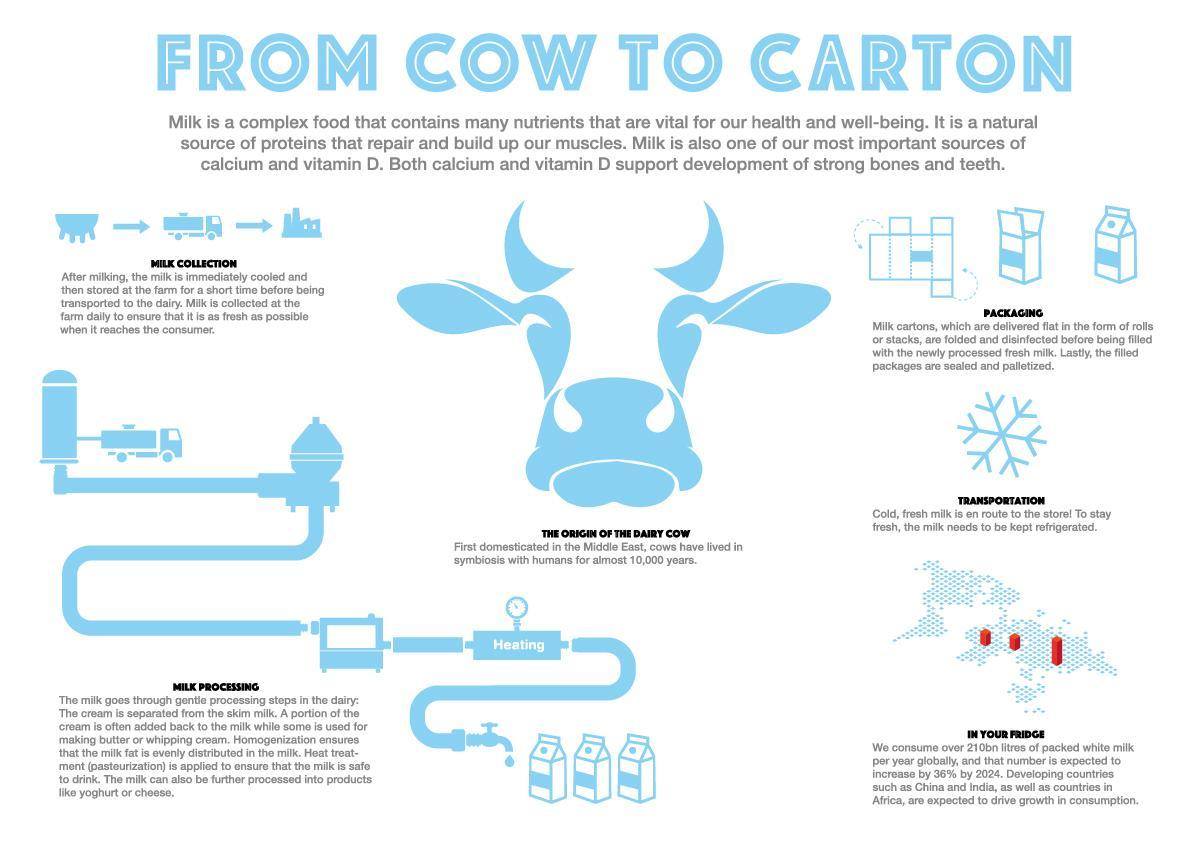

Nowadays, the popularity of tetra pak milk is increasing with more and more people moving towards this carton version. Carton milk, also called tetra pak milk is said to be the safest milk option and for all the right reasons. The packaging of tetra paks is usually done using UHT (ultra-high temperatures) method. In this, the milk is heated at a high temperature for a few seconds and then cooled down and immediately packed in tetra packs. This eliminates all the micro-organisms and pathogens present in the milk. Tetra Pak milk keeps well at normal temperatures for 15 to 30 days without refrigeration. The principle behind this is simple. Bacteria in fresh milk double every 20 minutes at normal temperatures.

So a million bacteria multiply to eight million in an hour and to 64 million in two hours, enough to curdle it. When temperature is brought down to within two to four degrees, the bacteria do not breed so fast.

But this is not possible without refrigeration. However, if the milk is chilled with all bacteria killed, and then sealed in airtight containers such as Tetra Pak, bacteria breeding can be kept under control and milk can be distributed at normal temperatures, unlike pasteurised milk, without refrigeration. Pasteurised milk will keep only when cold and has to be consumed quickly unless its life can be prolonged by keeping it in refrigerators which most Indian households don’t possess. Tetra Pak or asceptic milk will carry the white revolution further afield by roping in thousands – possibly millions – of households which are now outside the reach of the pasteurisation circuit. The Tetra Pak idea is not all that new but credit is due to Dr Verghese Kurien and his colleagues in the National Dairy Development Board for pushing the idea through the serried ranks of bureaucracy in New Delhi, which, like most bureaucrats everywhere, have difficulties for every solution.

About 52 years ago, in 1969, a private firm in Calcutta, Kant & Co, entered into a collaboration with Tetra Pak Development Limited of Switzerland for manufacturing laminated paper in the country. The company also received a letter of intent to set up a paper laminating plant and introduce Tetra Pak in India.

Since liquid milk business in the organised sector was almost entirely in the hands of the public and cooperative sectors, Dr Kurien argued and the Government agreed, that the paper laminating project should also be in the public sector. The Government cancelled the licence given to the private firm and asked the Indian Dairy Corporation to negotiate a new agreement with the Swiss company. There were, however, other problems. The Planning Commission suddenly discovered that 15-day-old milk would not be acceptable to the Indian consumer. Dr Kurien and others had in the meantime set up a Tetra Pak machine in Baroda for test marketing in Bombay and other places and the milk was reported to have met with wide acceptance by the general consumer. Some 40,000 packets of Tetra Pak milk were supplied for trial to the Indian army which carried it into battle at Barmer during the 1971 war with Pakistan.

What is a tetra pak?

Tetra Pak is a wonderful invention. The aseptic packaging can keep milk fresh for months without refrigeration. There are hundreds of products that are given extended shelf life with it.

A lot of people are unaware of the fact that consumption of fresh milk is always advisable, and just one boil is enough to retain the nutrients of milk. A recent survey conducted by Research Pacific India reveals that 60 per cent mothers are unaware about the nutrition loss in milk due to boiling. Even after the first boil, they continue boiling it for about seven minutes. If you’re buying milk from the milkman, the ideal way to consume it is to heat it at 100 degrees Celsius for less than 8 to 10 minutes.

Another great solution is to opt for tetra paks. With rampant adulteration and microbial contamination of milk causing varied health risks, the use of aseptic packaging is a boon for the white revolution. Using either UHT (ultra high temperatures) or HTST (high temperature short time), the milk is heated on a prescribed high temperature for only a few seconds and then cooled down and immediately aseptically packed in tetra paks. This not only prevents entry of any microbes but also helps retain the nutritional strength of the packaged product. Once you open the tetra pak, refrigerate it and consume the milk within two to five days.Apart from being environmentally friendly, aseptic packaging increases the shelf life of the product, eases its transportation and also prevents adulteration of any sort.There are many myths surrounding tetra paks. Tetra pack is the most common name for aseptic cartons used for liquid food items which have to be stored for up to one year without refrigeration. Aseptic here means “free from pathogenic micro-organisms, ” so this packaging process eliminates the food and packages from harmful elements. This type of packaging also blocks light completely to preserve vitamins A, B2, B6, B12, C and K, which are all photosensitive and would become damaged in the presence of light.

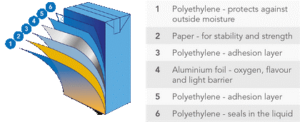

Structure of a Tetra pack:

A tetra pack is made of six layers i.e.

- Polyethylene – Contributes 15% of the total packaging; it protects from outside moisture.

- Paper – Contributes 80% of the total packaging for providing stability, strength and smoothness to the printing surface.

- Polyethylene – Polyethylene acts as an adhesive layer between other layers.

- Aluminum foil – Contributes 5% of the total packaging. It forms a barrier against light and oxygen, eliminating the need for refrigeration and preventing spoilage without using preservatives.

- Polyethylene – Acts as an adhesion layer.

- Polyethylene – Seals the Liquid from inside.

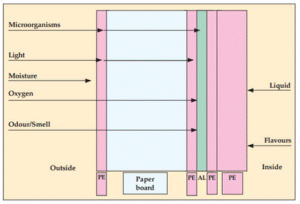

Diagrammatic Representation of Tetra pack acting as a Barrier.

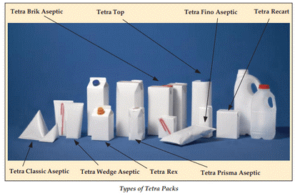

Types Of Tetra packs:

These packages come in various sizes and shape configurations. These packages also have a variety of openings and closures appropriate to product and consumer needs. Depending on the two points mentioned, following diagrams shows the types of tetra packs available.

A tetra pack comes under the category of aseptic packages. For a material to be aseptic, it should have the following features-

- The packaging material must be compatible with the product intended to be packed.

- The physical integrity of the package is necessary to assume containment of the product and maintenance of sterility.

- The packaging material must be able to withstand sterilization and be compatible with the methods of sterilization.

- The package must protect the product from oxygen; also, the package must retain the product’s aroma.

| PACKAGING CONTAINERS (FORMS) FOR MILK AND DAIRY PRODUCTS |

- Bottle

- The glass bottle still continues to be used for packaging of milk in some parts of the world. However in several developed countries and some of the developing countries it has lost ground to single service containers for packing milk.

- Carton

- The cartons are the preferred medium or form for packaging They are also used for packaging liquid, frozen and coagulated milk products. Cartons are commonly made of food grade paper coated on the inside with wax or plastics; or lined with paper, plastic films or aluminium foil; or made of laminates.

- The merits include maximum space utilization in vehicles, and storage; ability to carry attractive printing and convenience as a means for stacking milk at super market shelves.

- Retailers in the developed countries consider it the best available package for self-service selling. Cartons also play a role in the bulk packaging of milk. Cartons are commonly available either as preformed containers or as pre cut blanks ready to be formed in to containers. The carton systems in common use are as follows.

| Perga (preformed) | U.K |

| Pure pak (precut) | USA |

| Zupack, Blockpak (precut) | Germany |

| Tetra pak (precut) | Sweden |

- Sachet / Bag / Pouch

- Flexible waterproof plastic bags are commonly used for packagingmilk and liquid dairy products. Since it is difficult to pour from these, a jug is usually also provided. The popular laminate for such bag is black or dark brown (to exclude UV light) or white.

- The bags may be formed from either a reeled or flat film. Generally it is a form-fill-seal system. Generally, ultra violet light is used to sterilize the films. The bags are heat-sealed and cut, the common sequence being to bottom seal, fill, move down on sachet length, top seal and cut off.

- Can

- This is commonly used for packagingall types of solid, semi solid and powdered dairy products. Cans are traditionally made of soldered tin plate steel, generally lacquered on the inner surface to prevent corrosion.

- Aluminium cans have now become famous. Cans are the most convenient for gas packing.

- Box / Tub

- It may be made up of wood or paper board. White wooden boxes / tubs are used for bulk packing of butter and butteroil with butter paper / plastic liners, paperboard boxes are generally used as over-wraps.

- Barrel / Cask

- Commonly made up of wood and coated with wax on the inner surface. Used for bulk packaging of sweetened condensed milk, semi solid butter milk / whey, butteroil etc.

- Cup

- They are generally made up of paper with wax or plastic coating on the inside. Used for packing frozen dairy products such as ice cream and coagulated milk products.

- Collapsible tube

- They are made up of aluminium and lacquered on the inside. Low cost, lightweight, ease of handling and dispensing, product protection are its advantages. Used for packing semi fluid products such as sweetened condensed milk, processed cheese spread etc.

A summary of packaging materials / containers used in Dairy Industry

| S.No | Product | Packaging Material |

| 1. | Liquid milk | Glass bottles (obsolete) LDPE film in combination with LLDPE or octane / butane based films. Paper laminates for tetra packs |

| 2. | Milk Powder | Tin plate containers, nitrogen packed, and lacquered from outside. Flexible laminates such as metallized PET / BOPP / Aluminium foil / Poly laminates. Refill packs; lined cartons laminated with BOPP / PET, varnished on the outside. Paper laminated film is also used. Bag-in-box; Powder filled in laminate and packed in cartons. |

| 3. | Butter | Duplex board with vegetable parchment paper Tin plate containers Aluminium foil |

| 4. | Cheese / Cheese spread | Tin plate containers lacquered from inside First packed in aluminium foil and then in duplex board carton Injection moulded PP / HDPE container |

| 5. | Ghee | Tin plate containers lacquered from inside Glass bottles HDPE film pouches |

| 6. | Ice cream | Thermoformed / Injection moulded plastic containers Duplex board carton (poly laminated) Laminates of BOPP(Biaxially Oriented Polypropylene) / PET |

| 7. | Indian Dairy Products | Injection moulded / thermoformed containers (shrikhand, gulab jamun) Stand up laminated pouches |

PACKAGING MACHINES FOR MILK

The Form Fill Seal(FFS) machines are a genre of filling equipment that can fill in a flexible packing material. The product should be free flowing type, either liquid or even granular. The equipment may be controlled electro-pneumatically or mechanically.

The process involves certain steps, which will take place cyclically in auto operation.

There is option for variation in size and quantity of the product packed. To a large extent, the market milk is now being sold by packing in these machines.

The following are the operations that go cyclically.

- Forming of tube of packing material from film in rolled state

- Simultaneous operation of filling and sealing

- Movement of film to form next package

- Simultaneous separation of filled and sealed packet while filling of next packet.

Sequence of Operation

With reference to the fig. the film roll is loaded at the backside of the filling machine on a sliding platform. The film edge is passed over end of role contact lever, dancer roller, UV tube and brought to the front side over to forming plates. The forming plates rolled the flat film in to tube a certain band of overlap. Within the tube is the fluid filling pipe enveloped. The tube then passes over to vertical seal jaws that are engaged and disengaged with the help of an air operated piston, or in machines by mechanical means. In between the jaws, the overlapped part of the film tube passes. The set of jaws have one stationary and one moving jaw. The moving jaw has a nichrome rod, supplied with variable voltage such that the heat is generated when the current passes intermittently. During the period when the current does not pass, when the jaws are disengaged, the cooling water being circulated in the moving jaw, cools it and prevents continuous over heating of the sealing rod. The film is supported by Teflon cloth and rubber cushion, as well as protected by Teflon cloth from sealing rod. This arrangement prevents electricity passing on to the film and other parts, while allowing only the heat to pass on to the film and partly melting and fusing the vertical joint.

Lower down the film tube, there are a pair of nip rollers giving a holding and pulling down action, when the jaws are disengaged, making the film to move to seal the next portion of vertical overlap.

Further lower down the film tube is engaged by horizontal jaws, at a sufficiently below the lower edge of fluid filling pipe. This arrangement allows the formation of lower seal of the packet, while the fluid is being filled to a known quantity. The quantity of flow is controlled by a valve operated by a rod which is lifted by a solenoid coil position at the top of machine, just at the feeding line from the over head tank carrying the fluid to be filled. While filling is taking place, a pair of flat blades operated by spring keeps the film perfectly flat at horizontal edge so that there is no folds and horizontal seal is perfect.

When the filling of fluid and the horizontal sealing is complete, the horizontal jaws (as well as vertical jaws) get disengaged, and the nip rollers start rolling to bring the next length of film tube to be filled for next packet. While the second packet is being filled, the first packet already filled will be getting the horizontal seal of top portion of the filled packet. When the next time the jaws open, the first packet drops down by its own weight and weakened connection to the rest of the tube.

The above cycle of operation is repeated when the controls are in automatic operation, while single action takes place when in manual operation during initial adjustment of time and temperature combination for obtaining proper seal.

Controls

The Form Fill Seal Machine has various controls for the following operations.

- Adjusting the temperature of sealing rod by controlling the electric supply, to match to the thickness of the film to be sealed.

- Adjusting the timing for the jaws to be engaged and simultaneously filling operations to take place, with a known quantity of fluid.

- Adjusting the quantity of fluid to be filled when jaws are engaged

- Adjusting the timing for the jaws to be engaged and allow time for movement of film to the required length of package.

The other useful instrumentation are the end of film indicator (gives audio signal), so that the new film roll can be changed easily, fine adjustments for the quantity of fluid filled in few grams range, fine adjustment of timings, etc.

The equipment will require water for cooling the jaws at a fixed flow rate and of low temperature. Also, compressed air is required which is at required pressure and free of condensed moisture.

UHT milk packing machine

The UHT milk packing machine is different than the usual FFS machine in that the packaging material is multi layered, and the filling is done in an absolutely asceptic condition. The filling room is kept in a positive pressure, and the air inlet is through HEPA filters. Starting out from a reel of packaging material, the Tetra Brick Asceptic (TBA ) filling machine produces filled packages. The packaging material is first sterilized and then formed into a tube. The tube is filled with product and then shaped and cut into individual packages.

The package

There is a range of Asceptic packages , all deriving their origin from the same forming technique. In India, the commonly available Asceptic packaging machine is from Tetrapak company.

Package terminology

Creases are the folding instructions on the packaging material, to ensure the Creases package’s final shape. The creases are pressed into the material by the creasing tools in the converting process.

The longitudinal seal (LS) is accomplished when forming the packaging material seals into a tube. It seals the package along the side. A strip of laminated plastic, the LS-strip, covers the seal on the inside. The area of the overlap joint is called the longitudinal overlap.

The transversal seal (TS) is made when the tube is filled with product. It seals the package at top and bottom. The sealing takes place below the product level in the tube.

The fins are the areas, at top and bottom of the package, where it is sealed and Fins cut.

The flaps would be the corners of the package, if you flattened it out. When Flaps shaping the package, the flaps are folded down and in, and then sealed to the package body.

Machine introduction

Tetra Brik filling machines are built from so called modules or main groups with similar functions in the various machines. The machines may also have different additional equipment and accessories.

- ASU Automatic splicing unit(ASU): The automatic splicing unit splices reels of packaging material. This means that production can continue uninterrupted when one reel of packaging material comes to an end.

- During splicing though, the packaging material has to remain still in the splicing head. The magazine provides the necessary supply of material so that the machine does not have to stop.

PullTab unit

2.The PullTab unit is additional equipment, providing the packaging material with a PullTab opening before it enters the peroxide bath. The PullTab opening is created by punching a hole in the packaging material. The hole is sealed with plastic on the inside and aluminium on the outside.

- Strip applicator: The strip applicator applies a plastic strip, the LS-strip, along one edge of the packaging material. The strip is applied on the inside of the packaging material and is intended to prevent product from being soaked into the raw paper edge of the longitudinal seal. The strip will also support the seal. Only half of the LS-strip is sealed to this edge of the packaging material. The other half will be sealed to the other edge later, when the packaging material is formed into a tube.

- Peroxide bath: The packaging material will be sterilized in the peroxide bath. In machines with deep baths, as shown in the example, the packaging material will be immersed into warm peroxide and both sides will be sterilized. In machines with shallow baths the inside of the packaging material will merely be covered with cold peroxide and the sterilization will be finished in the tube heater.

- Aseptic chamber: The packaging material will be dried with heated air. In machines with deep baths, as shown in the example, an aseptic environment around the sterilized packaging material is maintained with an overpressure of heat-sterilized air. This takes place in the aseptic chamber. Machines with shallow baths, which have no aseptic chamber, heat-sterilized air will be blown into the tight tube. This way a sterile area is maintained where the tube is to be filled with product. The packaging material will be formed into a tube and sealed longitudinally. Finally, the tube will be filled with product.

- Jaw system: In the jaw system the tube is sealed transversally and cut into separate packages. The sealing is made by induction heating, using the aluminum in the packaging material to melt the plastic. It is important that the package design, with the creases, appear in accordance with the jaws. This is controlled and corrected by the jaw system.

- Final folder: In the final folder the separate package gets its final shape. The fins are folded and the flaps are folded and sealed. Hot air is used to seal the flaps. The plastic outer coating on the package material is heated and the flaps are pressed against the sides and the bottom of the package. When the plastic gets cool the flap is sealed.

- Operator panel: The operator panel allows the operator to communicate with the machine. It is used to start and stop or make the machine take any other action.

- Electrical cabinet: In the electrical cabinet a great part of the electrical components are included, such as:

- Temperature regulators

● Control system

● Contactors

● Induction Heating unit, etc.

- Service unit: The service unit includes parts and supply systems needed for the machine function, for example:

- Water and air system

● Lubrication and hydraulic oil system

● Pneumatic and peroxide systems

- Drive system: The drive system includes motor, gear and cam. These parts run the jaw system and also the final folder on certain machines.

Processes for Packaging Fluid Milk

- Processes for single-use packaging

The pouch-filling machine is an integral part of a modern fluid milk plant. Several types of plastic materials are used in forming the pouches. The material generally comes in the form of rolls, which are loaded onto the machine. The layer of plastic is folded vertically and sealed. A horizontal sealer seals the bottom of the pouch.Simultaneously, milk from an overhead float tank is siphoned into the formed cylinder.It is then again horizontally sealed at the top and cut off to form a pouch filled with milk. These machines come with adjustable filling heads capable of filling several volumes of milk as the need be.

- Processes for Multiple-use Packaging

The filling of milk in glass bottles was an important operation in the fluid milk factory till recent times when the sachet-packing systems gained popularity for several reasons. However, inspite of the weight of the bottle and the problems regarding the return and cleaning of bottles before refilling, it has several advantages such as ease of cleaning and ease of visual detection of spoilage and impurities.

The bottle-filling process is a cycle of events that follow one another. Clean bottles are filled in the bottle-filling machine and capped (generally with aluminium foil caps). The filled bottles are stacked in crates and sent for cold storage/refrigeration.The crates of empty bottles, after selling the product are returned to the factory.The crates are emptied and cleaned separately. The bottles go to the bottle washer,where the broken/chipped bottles are discarded and the clean, disinfected bottles are returned to the bottle-filling machine.

Bottles require the following properties: The shape of the bottle should be such that it facilitates easy cleaning and allows brushes and jets (of water and detergents) to act on the entire inner surface. The neck of the bottle should be joined to the body smoothly with no sharp and protruding angle. The base should be concave so that the sediments and residues collect in the center of the bottle rather than on the periphery, thus making cleaning easier.

The resistance of the bottle to shocks is influenced by shape, consistency of quality and the thickness of the glass. The bottles should also be able to resist the high internal pressures and temperatures created during in-bottle sterilization.Optical defects such as irregularities in the composition of glass, presence of air bubbles, deformations and coarseness in the surface or extraneous matter in the glass also decrease the resistance to mechanical and thermal shocks.The capacity of the bottle should be constant and consistent and should match with the capacity of the filling machine. The most common volumes in the market are one litre, 500 ml and 200 ml.

iii. Processes for Bulk Supply

The milk for bulk supply is generally processed and filled in containers manually.These may be cans of PET containers. Bulk milk is also sometimes supplied in small tankers or vans fitted with SS tanks.In the modern dairying countries where the bag-in-box-type of containers is used,the bags, which have a separate bung with a flexible tube attached, are supplied to the producers. The dairy owners use semi-automatic filling machines to fill directly into the box. When delivered to the caterers the filled box fits into a custom-built refrigeration unit with a prefitted, simple on-off tap. The tube on the bag is fed around the tap and cut off to open the bag and permit the product to be dispensed.

- Processes for Long-life Milk

Long-life milk is that milk from which most of the spoilage bacteria are removed so that the milk could be stored for a longer period than normal milk. Specific processes such as bactofugation, microfiltration, ultra-pasteurisation and ultra-high-temperature (UHT) processing help to increase the shelf life of milk.

Bactofugation is a method by which the bacteria in the milk are removed by centrifugation. This uses the theory that bacteria have higher density than milk and thus will separate out into the outer orbit during centrifugation and can be removed after the process. The bacteria-rich portion is separately sterilized and added to the centrifugally sterilized bulk of the milk. Any packaging systems for fluid milk packaging may be employed to pack and market the product. However, the packaging system has to be clean and the seals preferably hermetic, in order to avoid recontamination during packaging and storage.

Microfiltration is a non-thermal, pre-pasteurization step that can extend the shelf life of milk up to 45 days. The microfiltration process uses a ceramic filter membrane to remove spoilage bacteria from milk, thus extending shelf life. Because it is a non-thermal process, milk is less susceptible to heat-related sensory defects with a 90-day shelf life. Packaging systems that prevail for fluid milk packaging may be used to pack and sell the product.

Aseptic packaging is a technology wherein the product and package are separately sterilized, and the product is then filled into the package and the package sealed in a sterile environment. The product is commercially sterile (meaning that any pathogenic or other spoilage microorganisms have been destroyed) and shelf stable(does not require refrigeration or freezing). Containers for aseptic filling have traditionally been aluminum cans, high-barrier pouches and multi-layer, foil barrier boxes. Aseptic packaging using flexible materials is also employed where extended shelf life is required. Many aseptic packaging systems are based on form-fill-seal technologies that eliminate the need to ship preformed containers to the processor.That is, the processor procures the packaging material in the form of rolls or stacks and they are formed (shaped) during the filling process.

Plastic materials used in aseptic packaging of milk products are polyethylene,polypropylene, polystyrene as tubes, bottles or plastic film laminates with paperboard or aluminum in the form of cartons. High-pressure steam is used to sterilize product lines and hydrogen peroxide with heat of UV radiation for container materials. The popular commercial systems available for aseptic packaging of milk are Tetra Pak,Tetra Brick, Brick Pack, Combi Block, Pure Pak, Hind Pak, etc. Tetra Pak/ Tetra Brick packs are used to pack UHT-treated milk into pre-sterilized package in aseptic conditions. The first aseptic carton was the ‘Tetra Classic’. It was made from a roll of packaging material that had been sterilized in hydrogen peroxide,formed into a tube, filled with liquid, sealed transversely and cut into tetrahedron-shaped containers. Tetra Pak uses paperboard laminated with 10m LDPE from outside and 70-75m LDPE from inside. The Tetra Brick uses aluminum foil of 7-9m in addition to above laminates. The machinery needed for this system is very expensive.

Ultra-pasteurized products are produced under slightly less extreme conditions than aseptic processing. However, heat processing and clean packaging still play important roles. Ultra-pasteurized milk beverages are usually packaged in barrier-coated paperboard cartons, or HDPE or PET bottles. To prevent light degradation, PET bottles, which are clear as compared to HDPE bottles that are opaque, can be tinted and/or covered with full-body labels. A window in the label allows consumers to see the product.

Ultra-pasteurized bottles include a hermetic foil seal on the bottle mouth. This prevents contamination and enables the product to achieve a 90-day refrigerated shelf life. Some processors who want to obtain a slightly longer shelf life than the standard 14 days, but do not want to ultra-pasteurize the milk, may opt for an intermediate thermal process referred to as higher-heat-shorter-time. The shorter heat exposure can leave the milk free from the sensory defects associated with aseptic and ultra-pasteurization temperatures. The refrigerated shelf life for such products is about 30 days.

DISADVANTAGE OF CONSUMING BEVERAGES IN TETRA PACK

Healthy eating is a way of life, so it’s important to establish routines that are simple, realistic, and ultimately liveable. Food and Natural drinks are an important part of a balanced diet.

What is Tetra Pack?

It is a form of packaging that cannot be completely recycled. Tetra pack products are not nutritious. Heating on high-temperature losses most nutrients. And hence the need to fortify.

Tetra pack is made from a layer of waterproof plastic paper and laminated. It also contains nano preservatives and aluminum. Tetra pack cartons are made from wood in the form of paperboard, as well as thin layers of aluminium and polyethylene. The main disadvantage of tetra pack packaging is that it can not be completely recycled. Tetra pack is not healthier or tastier or an economical option but you see a lot of Tetra pack as the manufacturing units offer co-packaging space for third party production and manufacture thousands of pack in one day with a one-year shelf life. Tetra pack milk, juices, cheese, etc are not safe and healthy to drink. Tetra pack food once opened must be consumed within 2 days.

Tetra Pack cartons are made up of six layers which help protect the milk, juice, or juice drink inside from germs, sunlight, and air. Non-aseptic cartons (for fresh products with shorter shelf lives) don’t need aluminium. Because of this multi-layer system, cartons have often been viewed as composite products difficult to recycle and are not environmentally-friendly.

Tetra pack is an alternative to fresh milk, drink, or food, as it comes with a longer shelf life and can be stored at room temperature. It’s a good alternative for those who do not want to go and buy groceries on a monthly basis as you can stock up tetra pack milk for a year.

Myths related to tetra packaging:

- Tetra packaged milk needs boiling

No, boiling of tetra pack milk is an unnecessary step. Tetra packaging involves UHT treatment of milk into pre-sterilized packages in a sterile environment, thus there is no risk of contamination and therefore no need to boil the milk before use.

- Tetra packages are Sustainable

Tetra packs are recycled, but the recycled part is not used for manufacturing of tetra packs, hence they are said as non-sustainable. It is unclear whether this is because their paperboard needs to come from virgin sources to avoid contamination, or whether the quality of the recycled paperboard isn’t high enough to make new cartons, or there is some other reason. Whatever the reason, it is turned into office paper.

MYTH#1

Tetra pak milk and dairy products have added preservatives: The use of high heat (75 degrees Celsius for 15-20 sec or 138 degrees Celsius for 23 seconds) helps remove all micro-organisms from the milk including bacterial spores. This process, followed by packaging, is conducted in a sterile condition. The packing technique further helps prevent spoilage of the milk. All this together aids preservation and hence no additional preservatives are added.

MYTH#2

Tetra pak products are not nutritious: Heating on a high temperature for a very short time prevents the loss of most nutrients – something that occurs in the conventional method of boiling. Many homemakers repeatedly boil milk for long durations to ensure that all microbes are destroyed but in doing so, there is in turn a loss of all water-soluble vitamins. This is the reason why aseptically packaged milk and milk products have better nutritive value than other forms of bottled milk.

MYTH#3

Tetra pak milk needs boiling: Boiling of tetra pak milk is an unnecessary step that causes loss of many B complex vitamins plus leads to wastage of time and resources. The aseptic packaging involves transferring the UHT treated milk into pre-sterilised packages in a sterile environment, thus there is no risk of contamination and therefore no need to boil the milk before use. You can have it directly or warm it slightly to have it as a hot beverage.

MYTH#4

Tetra pak is not suitable for children: With hygienic packaging of unparalleled quality, tetra pak milk is extremely safe for a child’s growth and development. Easy usability, convenient portability, and better nutrient strength – all these factors make it a preferred choice for kids.

The Food Safety Standards Authority of India (FSSAI) has confirmed that 70 per cent of the milk available in the country is adulterated with detergent, glucose and skim milk powder. Hence, though we consume milk for its protein and calcium which may be retained post boiling too, tetra pak is an ideal option for packaged milk as it eliminates the chances of adulteration due to its absolutely hygienic processing and packaging methods.

Structure of a Tetra pack:

A tetra pack is made of six layers i.e.

- Polyethylene – Contributes 15% of the total packaging; it protects from outside moisture.

- Paper – Contributes 80% of the total packaging for providing stability, strength and smoothness to the printing surface.

- Polyethylene – Polyethylene acts as an adhesive layer between other layers.

- Aluminum foil – Contributes 5% of the total packaging. It forms a barrier against light and oxygen, eliminating the need for refrigeration and preventing spoilage without using preservatives.

- Polyethylene – Acts as an adhesion layer.

- Polyethylene – Seals the Liquid from inside.

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.