VALUE ADDITION IN POULTRY: PRESENT STATUS & SCOPE IN INDIA

Compiled, & shared by-DR. RAJESH KUMAR SINGH, (LIVESTOCK & POULTRY CONSULTANT), JAMSHEDPUR Post no 1328 Dt 22/07//2019

JHARKHAND,INDIA 9431309542, rajeshsinghvet@gmail.com

Value addition. in poultry plays in important

role in increasing the profits. The value

addition may be through nutritional

manipulations, processing and transgenesis.

Omega-3 enriched eggs and meats are

available in the market for premium price

developed by nutritional approaches .

Feeding the chicks with rich sources of

omega-3 fatty acids will aid in increasing

the levels of omega-3 fatty acids in eggs

and meat of the birds. Experiments on

fortification of Zinc and Vitamin B12 in

chicken egg and meat through dietary

manipulation for enhanced value addition

and shelf life are going on and need

commercialization. The second one is

through biotechnological approaches,

where in the gene (inter species) responsible

for specific trait can be made through

transgenesis. However, this approach is still

in primitive stage where in research is being

carried out. The commonly utilized method

for value addition is processing of the

poultry products. By value addition low

valued meats and by products can processed

in to a highly nutritious finished products

adding to the returns.

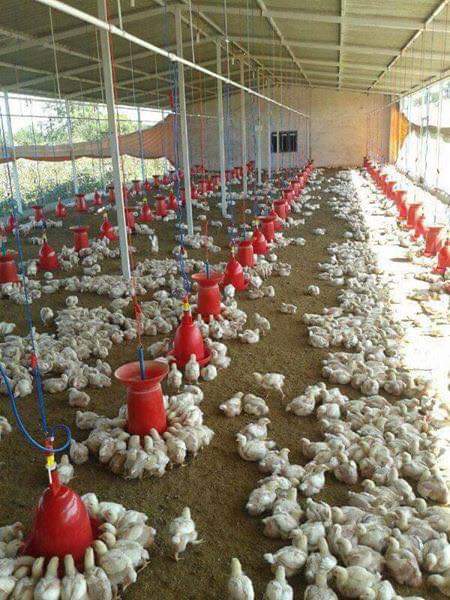

Poultry industry in India is a mega billion industry

having third position in egg production and fifth position in

broilers in the world. The total egg production accounts to

100 billion and broilers 3.8 billion. The average cumulative

growth rate in layer and broiler is 8% and 12 % respectively.

Even though production is in accelerated trend still

processing and marketing strategies are not in a well

defined manner which leads to overall moderate

profitability and less export promotion. This sector is

responsible for 0.45% of India’s Gross Domestic Product

(GDP) and 10% of livestock GDP. Poultry production in

India contributes to 5% of meat and 2.5 % egg of total

global output. Even though production is in faster rate, the

per capita consumption of egg and poultry meat is 62 eggs

and 3.4 Kg of meat. In India the consumption pattern varies

between urban and rural areas. In urban areas one third of

the population consumes two third of the poultry products

due to increased farm size, increased income and better

knowledge on health and nutritional benefits of poultry

meat. But in rural areas due to decreased knowledge on

nutritional benefits of poultry meat and poor families their

consumption is lower than urban people (Hai et al. 2008)

Irrespective of massive breakthrough in production front,

the processing sector is still in infantile stage and marketing

sector is mostly in disorganized way (Singh 2012)Currently

only 20 % of the chicken and 6% of the eggs are processed.

Among the dressed chickens, 70 % are sold as dressed or

chilled or frozen whole carcass, limiting remaining 30% to

cut up parts and further processed products. On the other

hand, in the industrialized countries, whole broiler sales recorded at 15%, cuts and boneless breast fillets 35%

further processed products 50%. Likewise 30% of the eggs produced are processed as pasteurized chilled-frozen liquid egg, dehydrated and ready to eat egg products. Right now, only dozen modern mechanized processing plants with capacity of 2000-4000 chicken per hour and three export oriented egg processing plants process the 4.5 million eggs per day (Singh 2012).

Major constraints in our country for lack of processing is

less preference for frozen chicken by the consumer,

insufficient cold chain infrastructure facilities, lack of well

organized marketing system, less domestic demand for

value-added egg products, non-availability of adequate

technology, fluctuating export trade, high import duty and

strict sanitary and phytosanitory norms by importing

countries. However, India with so many limitations now

emerged as a leading exporter of shell eggs, frozen and

dehydrated egg products and frozen broilers accounting to

Rs.458 crores during 2011-12. Indian poultry Industrial

growth is accelerated by gains in real per capita income and

changes in poultry prices.

2. Commercial Poultry Meat Products

Chicken meat products prepared from ground meat are emulsion based technologies which have the advantages of improved palatability, nutritive value and lesser production cost. Application of processing technology depends on global competitiveness, energy conservation and socio-

economic benefits.

2.1. Emulsion Products

Emulsion products like chicken meat blocks, nuggets, slices and patties utilizes tough meat, trimmings and edible by-products. The common steps of processing include comminuting/mincing to reduce meat and fat particle size (grinding, mincing, chopping or flaking), mixing with ingredients, making into specific shape, thermal processing and finally packaging.

Chicken nuggets are produced by making the meat batter into blocks and cutting the steam cooked and chilled meats into nuggets of different slices. Burgers/patties which contain 70% meat are prepared by mincing the meat, blending with ingredients, forming batter into patties which are cooked at 180°C (Anjaneyalu et al. 2012).

2.2. Processing of Sausages

Sausages are made by cutting meat and fat into fine

pieces mixed with spices and stuffed into animal intestines

and cooked in hot water. Emulsion based sausages are

made by grinding, chopping, stuffing, linking, cooking,

peeling, slicing and packaging. They are categorized by United States Department of Agriculture (USDA) meat inspection system as fresh, uncooked smoked, cooked, smoked, dry and semidry sausages and luncheon meat, loaves and jellied products (Anjaneyalu et al. 2012).

2.3. Restructured/Low Fat Chicken Products

These are meat products having high protein and low fat made by restructuring dark and white meat from heavy broilers. Excessive fat is trimmed off and other connective tissues are chunked out and formed. Blade tenderization, flaking and bay tumbling are modern methods available to produce tender products. Prepared meats can be used as steaks, cutlets, chops and roasts or they can be freezing stored (Anjaneyalu et al. 2012).

2.4. Cured and Smoked Products

Curing process involves addition of curing agents like

salt, sugar, sodium nitrite, sodium ascorbate and sodium

polyphosphate to the primal chicken cuts for enhancement

of colour, flavour and preservation. Chicken is injected

with pickle and dipped in it for faster curing giving a juicy

texture. Smoking involves heating, drying, smoking,

steaming/ cooking showering, chilling and packaging

which give a distinctive flavour. Cured and smoked chicken

on the whole has a niche market (Anjaneyalu et al. 2012).

. Enrobed/ Coated Products

Enrobing involves applying an edible coating to the products forimproving their texture, flavour, nutritive value, juiciness and tenderness. They act as sealing agents to prevent excess oil absorption. Chicken parts can be enrobed using whole egg liquid (viscous liquid and good batter), curd, flours, corn flakes and bread crumbs which give crispy taste (Anjaneyalu et al. 2012).

2.6. Retort Pouched Products

Thermal processing of meat destroys microorganisms and enzymes responsible for food spoilage. Thermal processing in metal cans or retort pouches increases shelf life of products and decreases 50% processing time. Some products include traditional Indian curries, soups, Keemas etc. Retort packaged products could be stored for a period of 6 to 12 months (Anjaneyalu et al. 2012).

2.7. Heritage Products

Heritage chicken products include traditional fast foods such as meat balls, kebabs, tikka, chicken tandoori, haleem, curries, enrobed and battered products and pickles which are prepared from chicken breast, thigh, drumstick and gizzard muscles. Pickles preserved with vinegar are stable up to 3 months (Anjaneyalu et al. 2012).

. Value Addition to Edible by Products

Edible poultry by products like dressed whole chicken

carcass and giblets such as liver, heart, gizzard and neck have good marketing values which are sold as package stuffed into cavity of carcass. Minced skin, gizzard and heart are used in emulsion of chicken products. Ova collected during dressing of layer chickens are used in sausage formulations, patties and kebabs. Chicken soup is another nutritious food that is categorized as low fat food (Anjaneyalu et al. 2012).

3. Commercial Egg Products

Egg products at USDA may be classified under following ways

(a) Refrigerated (as liquid) e.g. Whole eggs, whites or

yolks, sugared egg yolks, salted egg yolk, scrambled

egg mix, extended shelf life whole eggs

(b) Frozen: e.g. Whole egg, white or yolk, scrambled egg

mix, salted whole egg, sugared egg yolk and whole

egg mix

(c) Dried: e.g. White egg or yolk solids, dried egg, whole

egg

(d) Specialty products: e.g. dried hard cooked, peeled egg,

whole hard cooked peeled egg, egg yolk, long egg

quiche mix, and ultra-pasteurized liquid egg products.

Certain commercialized egg product preparations are as

follows

1. Pickled eggs: A simple, cost-effective and efficient

technology developed for ready to eat pickling of quail eggs/ chicken eggs for storage and marketing at ambient temperature.

2. Salted chicken eggs: Preparation of salted chicken

eggs technology is so simple to be used by unskilled people.

3. Albumen rings: Albumen rings are egg snack food,

prepared by cooking blended egg albumen in ring moulds and battering and breading the coagulated albumen prior to deep fat frying.

4. Egg roll: It is a nutritious, tasty and convenience egg

product suitable for meals or as snack foods.

5. Egg crepe: Egg crepe is a thin, fat, circular product

and may be filled with meat or vegetables and rolled or folded.

4.Advantage of Poultry Products

Marketing

Encouraging the poultry product marketing ensures

steady flow of products to the consumer in an effective

manner, thereby increasing the economic activity. It further

maintains the steady price distribution for the sale of

product in much profitable manner due to high returns. It

also gives way to employment generation and income

generation activity. Marketing of the poultry product can

also enhance the nutritional security of the different target

groups. Marketing of the poultry products make the poultry

products available at the right time, right place in right

quantity and at right price. However in India major problem

in marketing is the lack of efficient and organized market network.

4.1. Production Cost

In general the average variable cost of production is

lowest in the south followed by west, east and north. The

feed consumption rate (FCR) based market is generally

higher in the north because of higher market weight, higher

mortality rate due to extremes of hot and cold temperature.

Projected global egg and meat production during 2020 are

77 million tons and 123 million tons to cater to the demands of 8 million of the human population.

4.2. Channels of marketing

Currently more than 75% of the poultry products are

reaching the consumers through various channels of

distribution leading the consumers to pay more and

producers to get fewer margins. Besides, major share of the

profit at present goes to the middlemen. At present poultry

products are marketed in the following four marketing

networks.

1. Producer-Consumer

2. Producer- Wholesaler- Retailer- Consumer

3. Producer- Collector- Assembly merchant- Consumer

4. Producer- Retailer

Channel 2 may account to marketing of major portion of

eggs to the consumers. Channel 4 is responsible for getting

12-15% of the total profit to the retailers. However in

channel 2 a middleman gets 22% of the profit. National

Egg Coordination Committee owned by private sector

organization and National Agricultural Cooperative

Marketing Federation governed by Government of India to

some extent streamline the marketing of major poultry

products.

Major Meat consumption pattern in India are towards

fish, mutton, bovine and goat meat as given in the figure 1

below:

4.3. Prospects of Poultry Marketing

Considering the fast growth of the poultry industry in the past further growth and marketing of the poultry industry are limited due to the following factors

• Demand for poultry meat is highly price sensitive among low and middle income groups

Major limitation is logistics and distribution network within India mostly due to limited demands for frozen products, high cost of transport infrastructure unreliable cold chain facilities and the quality of the products produced.

• Vertical integration encourages higher production,

better marketing efficiency with reduced consumer

prices

• In India marketing efficiency is important than the

production efficiency

• Competitive feed price results in competitive meat and

egg production

• Seasonal variation due to religious practices

4.6. Prospects of Future Poultry Products Marketing

4.6.1. Strength: Technology Identified

4.6.1.1. Chicken Meat

Countinuous research and development efforts lead to

generation of cost-effective and efficient technologies for

the processing and preservation of egg and poultry meat,

tenderization of spent hen meat, deduction of meat

adulteration, development of value added poultry products,

packaging systems, optimum storage conditions, utilization

of poultry by-products etc. Besides, thorough inbuilt

measures are established to detect hazardous residues like

pesticides, antibiotics, antibacterial, heavy metals,

mycotoxins and biopathogens.

Currently some of the processing techniques include hot/cold deboning, thermal hydrolysis, enzymatic and blade tenderization of tough meat, massaging and tumbling for increasing myofibrillar proteins solubility and meat particle binding, flaking and dicing for restructured products, chopping and emulsification for comminuted products, marinating/ battering and breading for enrobed products, canning, curing and smoking and hurdle technology for shelf-stable poultry products.

Some of the value added poultry products include

chicken essence, chicken whey soup mixes, tandoori,

barbecues, canned/retort processed chicken products in

flexible pouches, cured and smoked chicken, chicken meat

and skin snacks, gizzard snacks, cooked chicken stock,

enrobed thighs, drumsticks and wings, marinated chicken

breast fillets, chicken spread, shelf- stable spiced chicken

bits, wafers, freeze- dried chicken pulav, retort- processed

curried chicken, and intermediate moisture chicken meat

etc. Other restructured products like chicken sausages,

patties/ burgers, nuggets, rolls, loaves, balls, cutlets, steaks,

kebabs, croquettes and chunkalona are other quality

products developed from low value spent hen or culled

breeder meat, skin, gizzard, heart, ova yolk and adipose fat.

4.6.1.2. Egg

Almost two-thirds of the global egg production has

occurred in developing regions of Asia. Egg processing is

mainly dominated by industrialized countries where 35% of

table eggs are converted into processed products. Table

eggs and liquid egg products are traded within European

and Asian countries. Dehydrated egg products are better

traded in large amounts because of its long shelf- life and

low transport cost.

India has also ventured in this on a modest scale. India’s

combined egg processing plants capacity is at 12000 metric

tons per year. Major areas of research in egg processing in

India is on design and fabrication of a low cost, batch -type

immersion egg washing machine and development of egg

washing powder. Recent advancements in egg processing

technology include improved egg spray washers and egg coating oil for preservation which maintains the quality of eggs up to 4 weeks at ambient temperature (26°C). Further processes have been developed to control gelatin in frozen yolk/whole egg liquid by 0.02% pepsin, 0.5% trypsin, 5 to 10% common salt or cane sugar or 5% glycerol in the egg magma prior to freezing.

Manufacturing technologies for a number of value-

added products live as whole egg powder, yolk granules, albumen flakes, albumen rings waffles, canned curried eggs, scrambled egg, omelet premixes, egg patties, egg- chicken meat patties, egg pizzas, egg roll, sponge and pancakes, albumen yolk cubes, mayonnaise, egg- enriched biscuits, breads and egg milk beverages have been adopted.

Ultra-pasteurization-cum-aseptic packaging techniques are also available to extend the refrigerated shelf-life of liquid egg up to 4 and 24 weeks at 10°C and 4°C respectively for marketing in non-frozen form. Presently another advanced method of vacuum evaporation of liquid whole egg followed by quick freezing to produce frozen egg pellets has also been developed.

Poultry slaughter waste, hatchery waste and egg shell

waste are being generated to the tune of three lakh tons, 0.6

lakh tons and 0.34 lakh tons respectively in India.

Conventional methods are being employed to convert the

egg shell into egg shell meal by centrifugation to recover

residual albumin subsequently with autoclaving, oven

drying and grinding into coarse or fine powder. Extrusion

technology has also been attempted to utilize the poultry

by-products into extruded pet food. Unorganized disposal

of poultry offal could be easily transported using 2% formic

acid or 4 % acetic acid for the period of 10 days at 26± 2°C.

Projected global egg production and meat production

during 2020 are 77 million tons and 123 million.

4.6.2. Weakness

4.6.2.1. Need for Emerging Technologies to Encourage

Marketing

Marketing of any products depend upon its shelf life ,

maintenance of nutrient content, easy transport, eco-

friendly packing material, easy availability, aesthetic

acceptance of the consumers. Accordingly there is a

necessity to concentrate on the research and development

wing to come out with newer technologies on the following

lines.

Design of mini poultry processing units

Shelf-life extension of poultry products by application of hurdle technology and biotechnology means

Developing newer techniques for tenderization of

meats

Efficient processing techniques for extraction of lysozyme, avidin, lecithin and other biomolecules from eggs

Ultra-pasteurization cum aseptic packaging technology for liquid egg

Uniform processing technology for traditional poultry products

Improved packaging techniques like vacuum, MAB, CAP, retort and aseptic

Development of quick and sensitive methods for detection of pathogens and hazardous feed residues Application of bio- processing techniques for efficient disposal of poultry products

User-friendly transport system as per the food engineering norms

4.6.2.2. Opportunities

Rapid urbanization, industrialization, rising disposable

income, changing food habits towards processed products

and higher middle income group are major positive factors

to boost up processed food markets. Strict adaptation of

GMP and HACCP system can give major possible export of

frozen broilers in the European Union, Japan and Russia as

per Rabo bank report 2008. Major limitation factor for

export of poultry products is attributed to non-compliance

of quality norms prescribed by the codex alimentarius.

Following are the major elements need to be given due

attention to encourage the export of poultry products

Application of modern processing techniques Provision of logistic support

Production of quality products fit for export Policy changes in the government level

Developing the appropriate packaging technology

Effective R & D work to increase the shelf life of the

products

Harmonization of quality control norms Single window approach for export

Creation of database

Well trained techno graphs and skilled human resources

NABL accredited laboratories for certification of food products

Cost effective mini poultry processing units

4.6.3. Threats

4.6.3.1. Marketing System

At present poultry marketing is dictated by the private

traders and commission agents present in various cities and

towns. Most of the trading activity of the poultry meat and

egg is in the disadvantageous position to the farmers giving

lesser margins of profit than the traders’ profit margin.

Right now, organized marketing network need to encourage

positive trend for uniform profits to all the players in the

poultry industry.

Indian Poultry Industry is one of the fast growing markets in poultry production accounting to 3.8 billion

broiler and 100 billion egg production. Although poultry industry shows enormous growth, the poultry processing

sector is still underdeveloped due to less demand for the ready to eat and cook products and less acceptability of

processed poultry products. At present marketing of poultry

products has many hurdles such as, unstable market,

increased taxes on processed foods, competitive feed costs,

high transportation charges, lack of cold chain facilities and

non-compliance of food safety norms. However continuous

research and development leads to the development of low

cost and efficient poultry processing technologies and well

established quality control norms. Poultry marketing

system in India dominated by private traders and

commission agents needs to be transformed into an

organized system for uniform sharing of profits by all

players in the industry.